Disconnect the negative battery cable. In case a radio device with an anti-theft device is installed. you need to know the code before disconnecting the battery.

Place a jack under the gearbox. It is even better if, with the help of a cable and a lifting mechanism, it is possible to raise the engine, removing it from the suspensions.

Disconnect the clutch cable from the gearbox as described above.

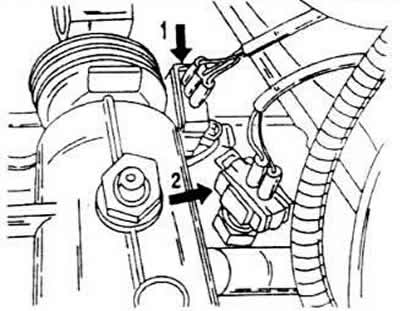

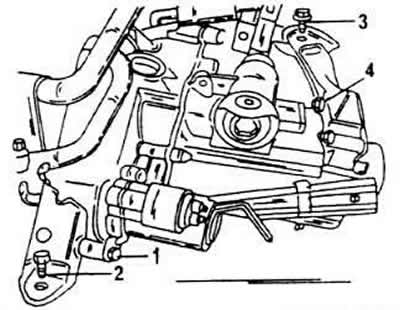

Disconnect all cables connected to the gearbox. One plug is connected to the tachometer sensor 1, the second is connected to the reversing light switch. Pull out both plugs.

Remove the top screws between the engine and gearbox.

Remove the screw from the right side of the engine mount (in the steering area). Depending on the version, there may be a plug attachment in this location. In this case, dismantle it.

After pulling out the locking segment keys, disconnect the front end of the lever and the end of the short shift lever from the shift handle.

Open the clamping element, and then disconnect the shift lever 1 from the intermediate lever.

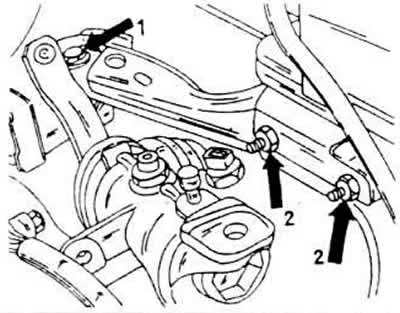

Turn out both top screws of a suspension bracket of a transmission from the left side of a transmission.

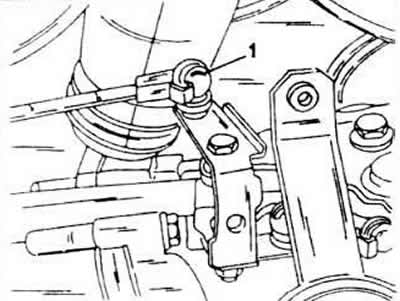

Disconnect the hex head screw 1 on the left side of the gearbox mount, and then unscrew both hex nuts.

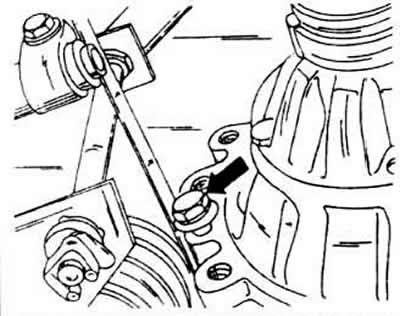

From the engine mount, unscrew the middle screw of the clamp used to mount the engine.

Use a cable and hoist to lift the engine and transmission out of the engine compartment until the drive is tensioned.

Remove the lower mudguard from under the car, if any.

Disconnect the starter and completely dismantle it.

Remove the front suspension.

Remove the fixing screws of the left engine mount.

Unscrew the large shield under the clutch and remove the small shield located behind the right flange on the drive side.

Disconnect the third gearbox suspension screw (arrow) and remove the hanger.

Adjust the lifting device to lower the gearbox slightly and remove the screws on the left gearbox bracket. Take out the bracket.

Unscrew input shafts from output elements of a transmission. Be sure to use a suitable set of wrenches, as there are screws with multi-toothed heads that resemble an internal hexagon. Tilt the steering gear to the left as far as possible and properly tighten the shafts with wire or cord to get them out of the way.

Move the engine and gearbox forward and lean to the right behind the suspension.

Check that the jack secures the gearbox perfectly and that the engine is secured with a cable and hoist. Remove the screws located on the underside between the engine and gearbox. This work must be done together. Now the gearbox must be pressed from the dowel pins, and the gearbox, together with the flange mounted on the right side of the drive, should be held next to the flywheel, and the drive shaft - next to the suspension.

The gearbox is mounted in sequence. reverse dismantling, subject to the following requirements.

Clean the finely splined profile of the clutch shaft well and lightly lubricate it with graphitized grease. Firm "Volkswagen" uses grease G 000 100 for this.

Before installing the gearbox, check that the intermediate plate fits perfectly on the engine guide bushings.

Check that the dowel pins are seated in the cylinder block and not in the gearbox. Otherwise, remove them from the gearbox and drive them into the cylinder block.

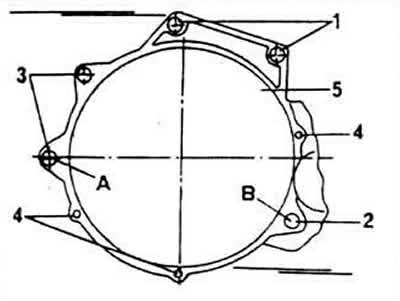

Tighten the individual screws connecting the engine and gearbox to the required tightening torques:

- 1 - M12 x 55, 80 Nm;

- 2 - M12 x 64, 80 Nm;

- 3 - M10 x 140, 60 Nm;

- 4 - M7 x 12, 10 Nm;

- 5 - Mb x 8, 10 Nm.

Tighten the starter screws to a torque of 60 Nm. flywheel cover screws - up to 10 Nm.

Before tightening the engine and transmission mounts, align the mounts until they are tight as described in the engine mounting section. In doing so, the following points must be observed:

- connection of the left suspension with the gearbox - 35 Nm;

- connection of the right carrier clamp of the engine with a subframe - 60 Nm;

- connection of the engine support with the subframe - 50 Nm;

- horizontal screw next to the starter - 45 Nm;

- engine mount screw (next to the starter, inserted vertically from above) - 60 N;

- screw 3 - 45 Nm;

- nuts 4 - 40 Nm.

After installing the gearbox, check the transmission oil level. The oil must be filled up to the lower edge of the oil fill hole. Otherwise, fill in the oil indicated in the table of dimensions and adjustment parameters to replenish the oil level.

Visitor comments