Warning: The gas pressure in a new gas-filled shock absorber reaches 25 bar, so be careful when disposing of a gas-filled shock absorber and use safety goggles.

The shock absorber can be disposed of in two ways: either by drilling a hole, or by cutting the shock absorber body.

Drilling shock absorber

1. Secure the shock absorber in a vise with the rod down.

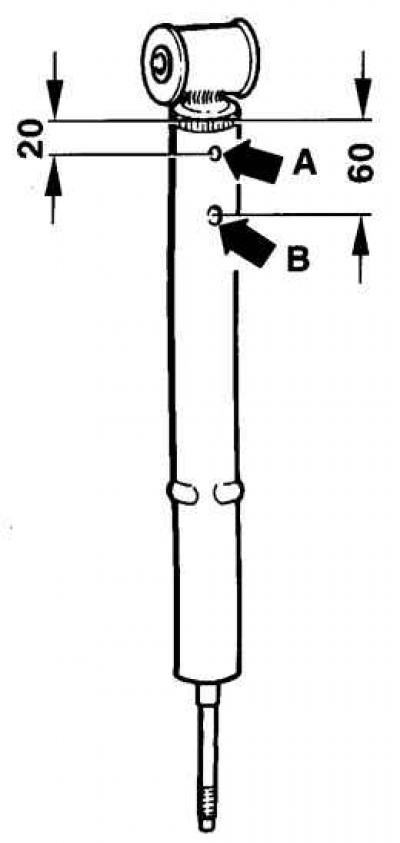

2. Using a 3 mm drill, drill hole A in the shock absorber housing.

Warning: When drilling a hole in the body of a gas-charged shock absorber, pressurized gas will escape. When gas escapes from the shock absorber, cover the hole with a rag.

3. Continuing drilling, drill the inner tube of the shock absorber (about 25 mm).

4. Using a 6mm drill bit, drill a second hole B in the shock body and inner tube (see fig. higher).

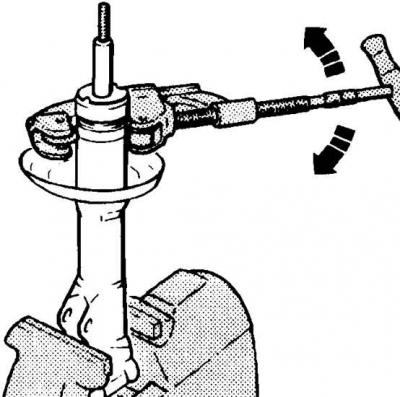

5. Install a suitable container under the shock absorber and, moving the shock absorber piston rod from stop to stop, squeeze the liquid out of the shock absorber.

6. After draining the fluid from the shock absorber, the shock absorber can be recycled.

Cutting shock absorber

1. Secure the shock absorber in a vertical position in a vise.

2. Install a pipe cutter on the top of the shock absorber body and cut the shock absorber body. In this case, no gas will escape from the gas-filled shock absorber.

3. Pull the damper rod up while holding the inner tube of the shock absorber in the shock body.

4. Remove the damper rod from the inner tube.

5. Drain the shock absorber fluid into a suitable container.

Visitor comments