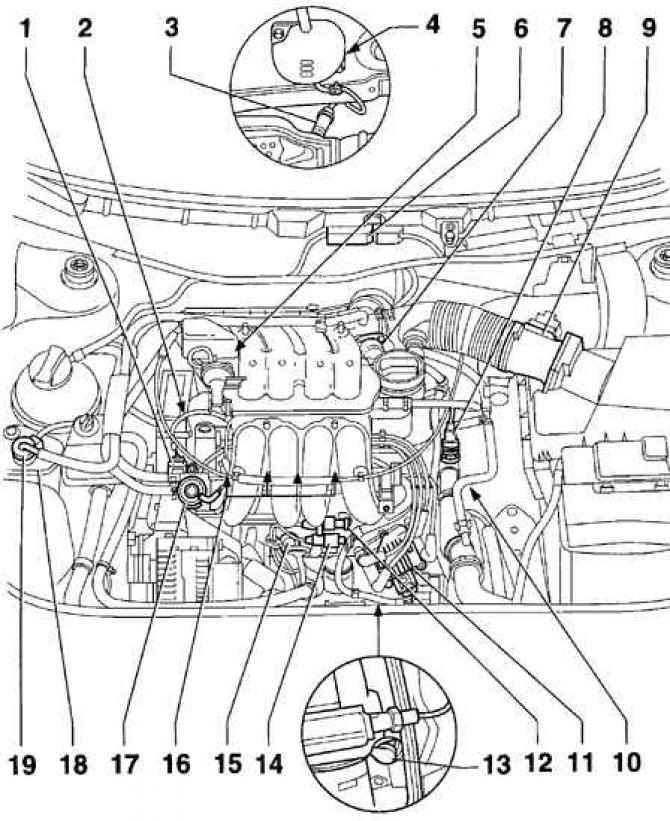

Location of elements of the SIMOS engine management system in the engine compartment with a 1.6-I engine

- 1 - Hall sensor electrical connector (black);

- 2 - Hall sensor. On the upper casing of the toothed belt;

- 3 - lambda sensor, 50 Nm. Mounting position with automatic transmission in the exhaust manifold;

- 4 - electrical connector of the lambda sensor. On the underside of the car, on the right;

- 5 - intake manifold switching valve;

- 6 - SIMOS control unit;

- 7 - throttle body;

- 8 - coolant temperature sensor;

- 9 - air flow meter. With a temperature sensor for air entering the engine;

- 10 - the place of connection of the ground bus to the gearbox;

- 11 - ignition coils. With ignition control unit;

- 12 - electrical connector of the knock sensor;

- 13 - engine speed sensor;

- 14 - electrical connector of the engine speed sensor (grey);

- 15 - knock sensor;

- 16 - fuel injectors;

- 17 - fuel pressure regulator;

- 18 - canister with charcoal;

- 19 - magnetic valve of the charcoal canister

On vehicles with gasoline engines, various engine management systems are installed.

| Engine | Engine management system |

| Engine 1.4-I | AHW/ AKQ Magneti Marelli 4AV |

| Engine 1.6-I | AEH/ AKL Simos 2 |

| Engine 1.8-I | AGN Motronic 3.8.5 |

| Engine 1.8-I | Turbo AGU Motronic 3.8.3 |

| Engine 2.3-I | AGZ Motronic 3.8.3 |

The use of an electronic engine management system has the following advantages:

- provides optimal fuel supply to the engine in all operating modes, resulting in reduced fuel consumption while maintaining the dynamic characteristics of the car;

- due to more complete combustion of fuel, as well as the use of a catalyst, the emission of harmful substances along with exhaust gases decreases;

- since the electronic engine management system determines and records faults in the memory, the search and detection of faults is significantly accelerated;

- the engine management system in all operating modes sets the optimal ignition timing, the moment and the amount of fuel supplied to the engine. Also, the engine management system interacts with other vehicle systems, in particular, with the automatic transmission control system or with the anti-theft system.

Engine management components are very reliable and virtually maintenance free. During maintenance, it is only necessary to replace the air filter and spark plugs. Since it is necessary to use complex expensive equipment to check, adjust and repair the engine control system, this work must be done at a specialized service station.

During the operation of the car, it is not required to adjust the idle speed and the CO content in the exhaust gases.

Warning: When working on the ignition system with the ignition on, care must be taken, as you can get an electric shock from the high-voltage part of the ignition system. People with cardiac stimulants are not recommended to check and repair the engine management system. Switch off the ignition before disconnecting or connecting any element of the ignition system or tester probes.

Warning: The fuel system is under constant pressure even after the engine has been switched off, so any work on the fuel system must be relieved of pressure.

Warning: To prevent the possibility of accidental short circuits and damage to the electronic components of the engine control system, always remove the ground wire from the battery.

Before performing any work on the engine management system, recall the malfunctions recorded in it. Also check the tightness of the fuel system and the air supply system to the engine.

Normal operation of the engine management system is possible only if the voltage in the vehicle network is not lower than 11.5 V.

If, after working on the engine management system, the engine starts and stops after a short time, the engine may be switched off by the anti-theft system. In this case, recall the malfunctions recorded in the memory and, if necessary, adjust the engine management system.

Visitor comments