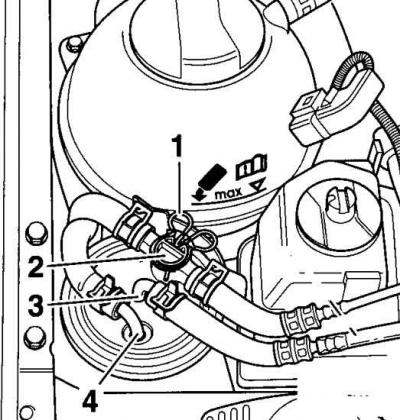

Fuel filter for diesel engines

- 1 - spring clip;

- 2 - valve;

- 3 - fuel pipe;

- 4 - fuel pipe

The engine together with the gearbox is removed from the car down from the engine compartment. When removing the power unit, a crane must be used. Also, the power unit can be lowered using a special lift with engine holders.

In order to provide sufficient working space under the vehicle, it is necessary to use four jack stands or a car lift with a platform or a viewing hole.

Depending on the course of manufacture and vehicle equipment, electrical wires, pipelines and hoses may be located in the engine compartment in different ways. Therefore, before disconnecting electrical connectors and disconnecting pipes or hoses, it is recommended to mark them with adhesive tape.

Necessary special tools and aids:

- crane for lifting the engine;

- collet for tape clamps;

- lifting grip;

- lubricant based on molybdenum disulfide;

- torque wrench providing tightening torques of 5–50 Nm;

- torque wrench providing tightening torques of 40–200 Nm;

- clamp.

Removing

Warning: All clips and clamps that are unscrewed or cut when removing the engine must be installed when assembling the engine in the same places, so their mounting position can be marked with adhesive tape. When disconnecting the electrical connectors, release the fixing wire and then disconnect the electrical connector.

1. Remove the ground wire from the battery.

Warning: Disconnecting the battery will erase the contents of the memory locations, such as the radio code. Without a code, the radio can only be reconnected by the manufacturer.

2. Remove the battery.

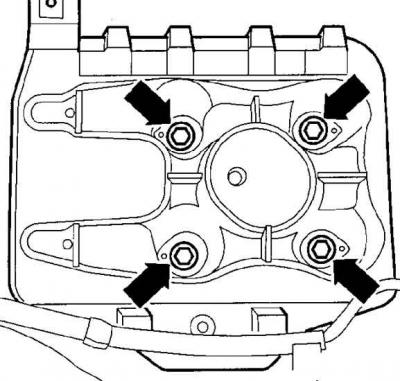

3. Unscrew the battery holders and remove them (the arrows indicate the nuts for fastening the battery holder).

4. Remove the starter.

5. Remove the lower mudguard of the engine compartment.

6. Unscrew the left and right drive shafts from the gearbox flange. Using soft wire, tie the ends of the drive shafts to the anti-roll bar or body.

7. Drain the coolant from the cooling system.

TDI engine

8. Remove the pipe connecting the charge air cooler and the intake manifold.

SDI engine

9. Remove the pipe connecting the charge air cooler and the air filter.

10. Release the tension and remove the V-ribbed belt.

Remove the starter.

11. Unscrew the power steering pump from the bracket and, using a soft wire, hang it from the body. Do not disconnect hoses from pump or kink hoses.

Vehicles with air conditioning

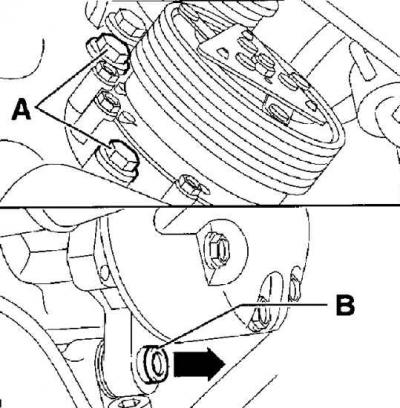

12. Unscrew the screws securing the air conditioning compressor and, without disconnecting the hoses from it, move the compressor to the side and secure it with soft wire (A - top bolt, B - bottom bolt).

Warning: Do not disconnect the air conditioning piping.

13. Remove the exhaust pipe and catalytic converter.

14. Loosen the clamps, mark and disconnect the vacuum hose and the air intake pipe from the turbocharger.

15. Disconnect all electrical connectors from the engine and transmission.

16. Release the spring clip (1) (see fig. Fuel filter for diesel engines) and remove the hose assembly from the valve (2). Loosen the clamps and remove the fuel hoses from the fittings (3 and 4). Cover the ends of the fuel hoses with foil or suitable plugs to prevent dirt from entering them.

17. Disconnect the coolant supply hoses to the heater core from the bulkhead of the engine compartment.

18. Disconnect the hoses going to the expansion tank from the engine and body and move them to the side.

19. Disconnect the pipes of the cooling system from the radiator.

20. Lift and secure the expansion tank together with the bracket.

Vehicles with manual transmission

21. Disconnect the shift mechanism and clutch slave cylinder from the transmission.

Warning: After removing the clutch slave cylinder, do not depress the clutch pedal.

Vehicles with automatic transmission

22. Unscrew the brackets securing the power steering pressure pipe to the gearbox. Disconnect the automatic transmission control cable from the transmission lever.

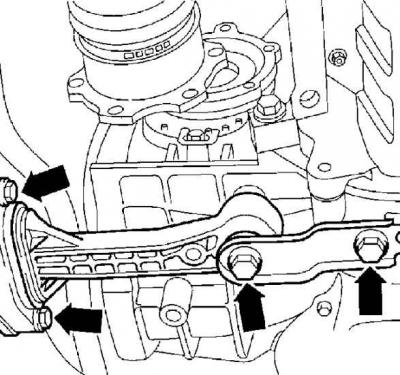

23. Unscrew the bolts at the bottom of the engine compartment (indicated by arrows) and remove the pendulum support supporting the engine and transmission.

24. Raise the vehicle so that the distance between the vehicle and the ground is at least 60 cm.

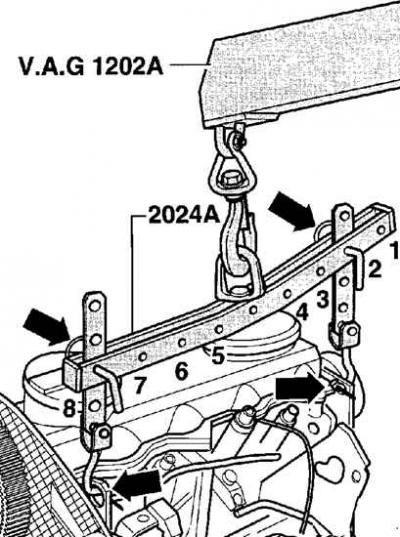

Removing the power unit with a crane

1. Place a 30 x 40 cm wooden deck about 15 cm thick under the engine oil pan.

2. Using the special tool, hook the power unit on the lifting eyes to lift the power unit.

3. If special tools are not available to support the engine, use a chain.

4. Raise the load handler until the weight of the power package is supported by the load handler.

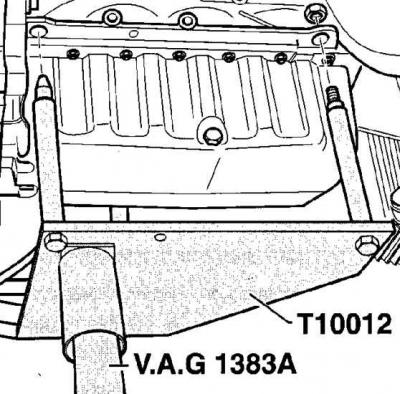

Removing the engine with a special holder

The special holder is a VAG 1383A hydraulic lift with a T10012 engine holder.

1. Install the special engine holder from below into the hole near the oil pan and secure the engine with nuts, tightening them to a torque of 25 Nm. Raise the engine holder just enough so that the weight of the power package is supported by the holder.

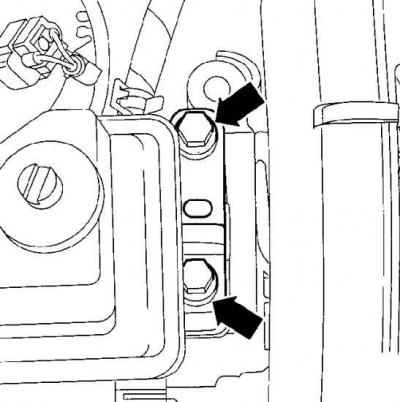

2. Unscrew the bolts securing the right upper support of the power unit (indicated by arrows).

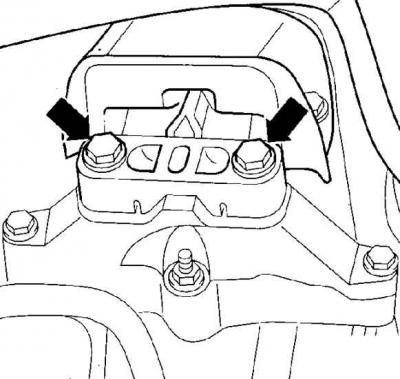

3. unscrew the bolts (indicated by arrows) and remove the left power unit support.

4. Check that all electrical connectors and hoses connecting the engine and gearbox to the body are disconnected.

5. When removing the engine using a crane, move the power unit forward and carefully lower it onto a wooden stand. Secure the power unit in such a way as to prevent it from tipping over.

6. If necessary, disconnect the gearbox from the engine.

Installation

1. Check the condition of the power unit supports and hoses for cracks or wear and replace if necessary.

2. If the gearbox has been disconnected from the engine, check the condition of the clutch.

3. Install the power unit in the engine compartment and align it as follows.

4. Install the right power unit mount with new bolts, hand-tight at this point.

5. Secure the power unit pendulum support with new bolts, finger-tight at this stage.

6. Torque tighten power unit mounts (see table. Tightening torques).

Warning: Unless specified, standard bolt torques are: M8 - 20 Nm, M10 - 45 Nm and M12 - 60 Nm.

7. If the compressor was removed, fix it with bolts, tightening them with a torque of 45 Nm.

8. Install the servo pump.

9. Install starter.

10. Install the V-ribbed belt and adjust its tension.

TDI diesel engine

11. Install the pipe connecting the charge air cooler and the intake manifold and secure it with clamps.

SDI diesel engine

12. Install the pipe connecting the intake manifold and air filter.

13. Install the exhaust pipe and catalytic converter with new gaskets.

14. Install the right and left drive shafts.

15. Connect the coolant supply hoses to the heater core on the bulkhead of the engine compartment and secure them with clamps.

16. Install the radiator fan.

Vehicles with manual transmission

17. Connect the shift rods to the gearbox. Install the clutch slave cylinder.

Vehicles with automatic transmission

18. Install and secure the power steering pressure pipe bracket to the transmission. Connect the control cable to the gearbox and adjust it.

19. Connect the disconnected electrical connectors and pipelines to the power unit, securing them with clamps.

20. Connect fuel hoses to nozzles (3 and 4, see fig. Fuel filter for diesel engines) fuel filter. The arrow on the fuel filter indicates the direction of fuel flow.

21. Reinstall and secure the battery holder.

22. Reinstall the battery, but do not connect the ground wire to it at this stage.

23. Install the valve (2) and secure it with a spring clip (1, see fig. Fuel filter for diesel engines).

24. Check that the electrical connectors and piping are properly connected to the power unit.

25. Check the oil level in the engine and gearbox and top up if necessary.

26. Fill the cooling system with coolant.

27. Install the engine top cover.

28. Install the lower engine compartment mudguard.

29. Connect ground wire to battery.

Warning: Activate the power windows and also set the clock and enter the code into the radio.

30. Start and warm up the engine to normal operating temperature.

31. Check oil and coolant levels and all connections for leaks.

32. Visually check that the adjustments are correct.

Tightening torques

| Connection points | Tightening torques |

| engine to bracket | 60 Nm + tighten by 90° |

| Gearbox to bracket | 60 Nm + tighten by 90° |

| Pendulum support to gearbox | 40 Nm + tighten by 90° |

| Pendulum support to the body | 20 Nm + tighten by 90° |

Visitor comments