Warning: When installing a new cylinder head, remove the plastic plugs to protect the open cylinder head valves.

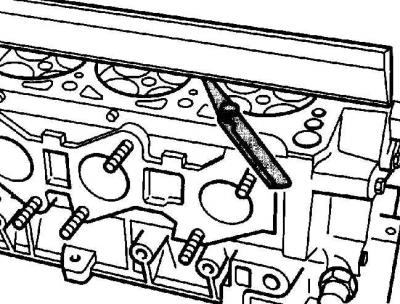

1. The mating surfaces of the head and cylinder block must be perfectly clean. Use a hard plastic or wooden scraper to clean them. Be careful when cleaning as aluminum alloy is very easy to damage.

2. Check that carbon deposits do not get into the oil and water channels. This is especially important for the lubrication system, as deposits can block the oil supply to engine components. Clean channels if necessary.

3. Using a metal ruler and feeler gauge, check the flatness of the mating surfaces.

4. The deviation from flatness should be no more than 0.1 mm.

5. Check the mating surfaces of the cylinder head and block for nicks, deep scratches or other damage. If the defects are small, they can be removed by machining.

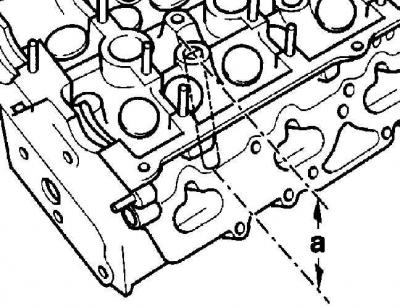

Measure your height (A) cylinder head in the specified location. The height of the cylinder head after machining should be 1.8 l = 139.2 mm for the engine, and 132.6 mm for the 1.6 l engine.

6. Clean the bolt holes in the cylinder block. Screwing a bolt into an oil-filled hole can rupture the block due to hydraulic pressure.

Warning: When installing the cylinder head, it is necessary to use new cylinder head bolts and a new cylinder head gasket.

Visitor comments