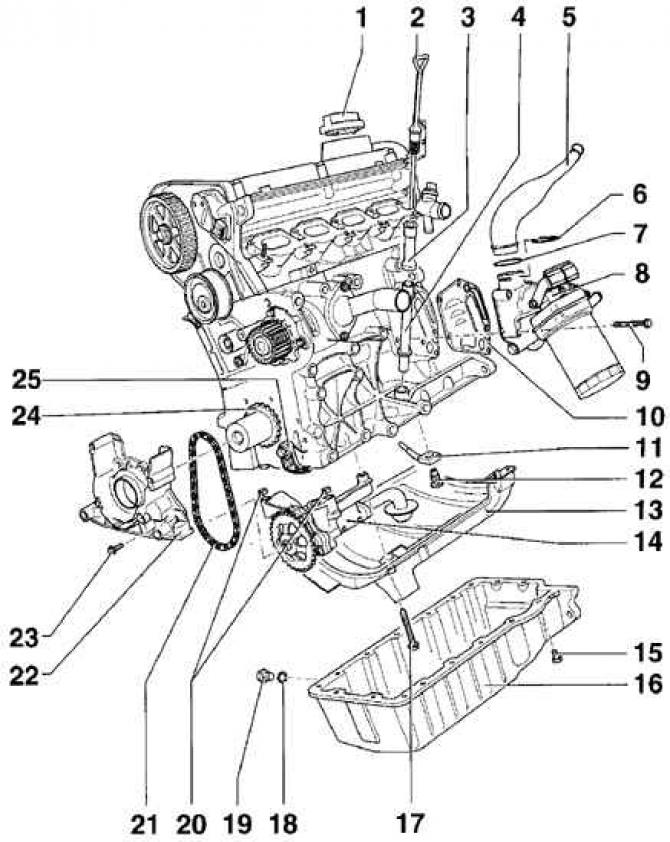

Elements of the lubrication system of a four-cylinder engine 1.8-I

- 1 - oil filler cap. If the cover seal is damaged, it must be replaced;

- 2 - dipstick for measuring the oil level;

- 3 - return funnel;

- 4 - guide pipe;

- 5 - connecting pipe. To the air intake sleeve. Only engines 1.8-I;

- 6 - fixing bracket;

- 7 - O-ring. If damaged, use a new ring;

- 8 - oil filter bracket with heat exchanger and oil filter. Tighten the oil filter by hand;

- 9 - bolt, 25 Nm;

- 10 - corrugated seal (sheet metal). When installing, use a new seal;

- 11 - oil spray nozzle. Designed for piston cooling;

- 12 - safety valve; 27 Nm. Valve opening pressure 2.5–3.2 bar;

- 13 - oil deflector;

- 14 - oil pump with chain sprocket;

- 15 - bolt, 15 Nm. Unscrewing the bolts must be done with a wrench with a hinge;

- 16 - oil pan. The oil pan is installed without a gasket on the sealant D 176 404 A4;

- 17 - bolt, 15 Nm;

- 18 - sealing ring. At installation it is necessary to use a new sealing ring;

- 19 - oil drain plug, 40 Nm;

- 20 - adapter sleeve. Designed to center the oil pump;

- 21 - oil pump drive circuit. Before removing the chain with paint, mark the direction of rotation of the chain;

- 22 - gasket. The gasket is installed on the sealant D 176 404 A2;

- 23 - bolt, 15 Nm;

- 24 - asterisk;

- 25 - chain tensioner, 15 Nm

If the oil pressure warning light comes on and the horn sounds while the engine is running, this may be due to the following reasons:

- the oil level is below normal;

- the presence of a malfunction in the electrical circuit of the pressure sensor and the control lamp;

- unsatisfactory operation of the oil pump;

- too much clearance in the crankshaft bearings.

If the oil pressure warning light comes on with the engine running, turn off the engine immediately. Using the dipstick to measure the engine oil level, check the oil level and top up if necessary. Run the engine at idle and check that the oil pressure warning light is no longer on. In this case, you can continue driving.

If the engine oil level is normal and the oil pressure warning light is on, do not drive on your own, but have the vehicle towed to a workshop to have the oil pressure checked.

If the oil pressure is normal, check the oil pressure sensor and sensor circuit.

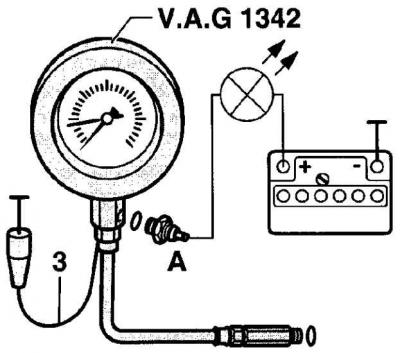

To check the oil pressure and the oil pressure sensor, you must use a special pressure gauge into which the oil pressure sensor can be screwed.

Order of execution

1. Check the engine oil level and top up if necessary.

2. Warm up the engine to normal operating temperature.

3. Unscrew the sensor from the oil filter holder (A) oil pressure and screw it into the pressure gauge (3 - pressure gauge ground wire).

4. Screw the pressure gauge adapter in place of the oil pressure gauge into the oil filter holder.

5. Connect the pressure gauge ground wire to the vehicle ground.

6. Using additional wires, connect the control LED to the positive terminal of the battery and the contact of the oil pressure sensor. The LED should be on.

7. Start the engine and gradually increase the engine speed. With an overpressure in petrol engines 1.4-I - 10.3-0.7 bar and engines 1.6-/1.8-/2.3-I - 1.2-1.6 bar, the LED should go out. Otherwise, the oil pressure sensor is defective.

8. Increase engine speed to 2,000 rpm. At an oil temperature of +80°C, the excess oil pressure must be at least 2.0 bar. Less oil pressure indicates worn crankshaft bearings.

9. Continue increasing engine speed further. The oil pressure must not exceed 7.0 bar. Otherwise, the bypass valve has failed and it is necessary to replace the oil pump cover with the bypass valve.

10. Reinstall the oil pressure switch with a new O-ring and tighten to 25 Nm.

Visitor comments