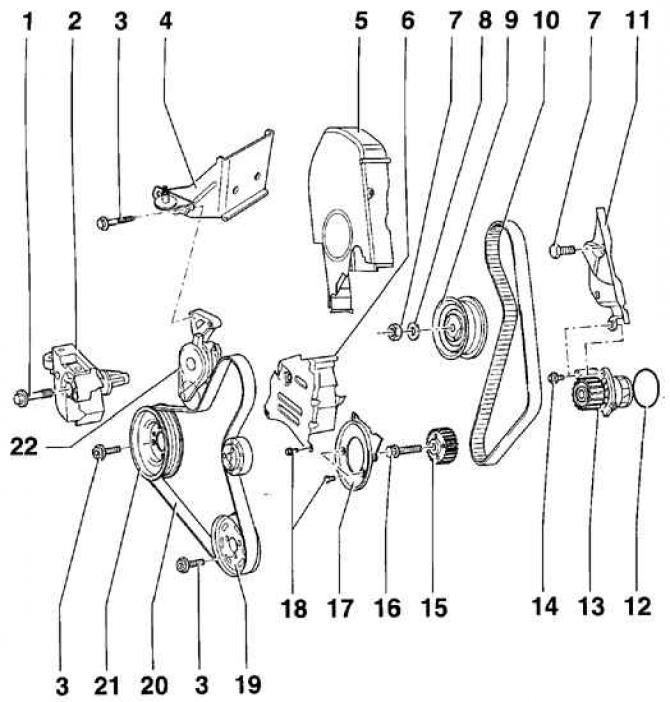

- 1 - bolt, 45 Nm;

- 2 - support of the power unit;

- 3 - bolt, 25 Nm;

- 4 - bracket;

- 5 - upper casing of the toothed belt;

- 6 - an average casing of a gear belt;

- 7 - nut, 20 Nm;

- 8 - washer;

- 9 - tension roller;

- 10 - toothed belt. Check the toothed belt for wear before installation. Before removing the toothed belt, note the direction of rotation. It is forbidden to bend the toothed belt;

- 11 - rear casing of the toothed belt;

- 12 - O-ring. When installing, use a new ring;

- 13 - water pump;

- 14 - bolt, 15 Nm;

- 15 - crankshaft toothed belt pulley;

- 16 - bolt, 90 Nm and tighten by 90°. When installing, a new bolt must be used. Turning the bolt 90°can be done in several steps;

- 17 - lower casing of the toothed belt;

- 18 - bolt, 10 Nm;

- 19 - belt pulley of the servo pump;

- 20 - V-belt. Before removing, note the direction of rotation of the belt;

- 21 - crankshaft belt pulley. Installation of the pulley is possible only in one position due to the displacement of the mounting holes;

- 22 - V-belt tensioning mechanism. To loosen the tension of the V-belt, use a wrench to move the tensioner to the side

Timing belt tension in four-cylinder gasoline engines is carried out by an automatic tensioner roller that maintains optimal belt tension, resulting in increased life and smooth running of the timing belt.

Order of execution

1. Remove the auxiliary V-belt.

2. Unscrew the auxiliary V-belt tensioner.

Visitor comments