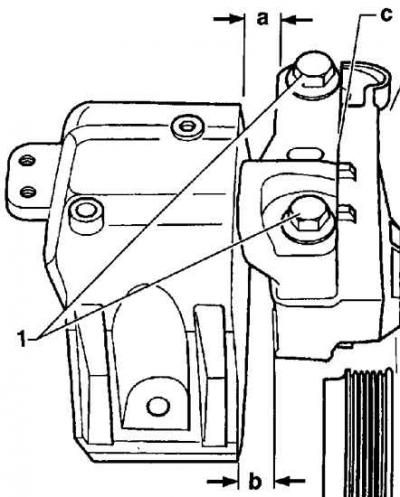

Alignment of the right support of the power unit

- 1 - bolt;

- A = 14 mm;

- B = at least 10 mm;

- C - bolt head flange alignment

Order of execution

1. Check the condition of the power unit supports and hoses for cracks or wear and replace if necessary.

2. If the gearbox has been disconnected from the engine, check the condition of the clutch.

3. Install the power unit in the engine compartment and align it as follows.

4. Install the right power unit mount with new bolts, hand-tight at this point.

5. Secure the power unit pendulum support with new bolts, finger-tight at this stage.

6. Align the right support of the power unit in accordance with fig. Alignment of the right support of the power unit.

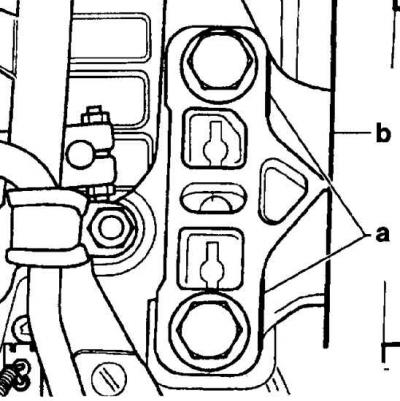

7. Align the left power unit support so that the ends (A) And (b) were parallel to each other.

8. Torque tighten power unit mounts (engines 1.4-/ 1.6-/ 1.8-/ 2.3):

- motor to bracket: 60 Nm + tighten by 90°;

- gearbox to bracket: 60 Nm + tighten by 90°;

- pendulum support to gearbox: 40 Nm + tighten by 90°;

- pendulum support to body: 20 Nm + tighten by 90°.

Warning: Unless specified, standard bolt torques are: M8 - 20 Nm, M10 - 45 Nm and M12 - 60 Nm.

9. Install the servo pump.

10. Install starter.

11. Install the V-belt and adjust its tension.

12. Install the air intake duct.

13. Install the air filter housing.

Engine 1.8-I-Turbo

14. Install the connecting pipes connecting the turbocharger to the charge air cooler, air filter and secure them with clamps.

15. Install the exhaust pipe and catalytic converter with new gaskets.

16. Install the right and left drive shafts.

17. Install the accelerator cable and adjust it.

18. Connect the supply and return fuel hoses to the fuel line and secure them with clamps.

19. Connect the coolant supply hoses to the heater core on the bulkhead of the engine compartment and secure them with clamps.

20. Install the radiator fan.

Vehicles with manual transmission

21. Connect the shift rods to the gearbox. Install the clutch slave cylinder.

Vehicles with automatic transmission

22. Install and secure the power steering pressure pipe bracket to the transmission. Connect the control cable to the gearbox and adjust it. Connect the disconnected electrical connectors and pipelines to the power unit, securing them with clamps.

23. Reinstall and secure the battery holder.

24. Reinstall the battery, but do not connect the ground wire to it at this stage.

25. Check that the electrical connectors and piping are properly connected to the power unit.

26. Check the oil level in the engine and gearbox and top up if necessary.

27. Pour coolant into the cooling system.

28. Install the engine top cover.

29. Install the lower engine compartment mudguard.

30. Connect ground wire to battery.

Warning: Activate the power windows and also set the clock and enter the code into the radio.

31. Start and warm up the engine to normal operating temperature.

32. Check oil and coolant levels and all connections for leaks.

33. Visually check that the adjustments are correct.

Visitor comments