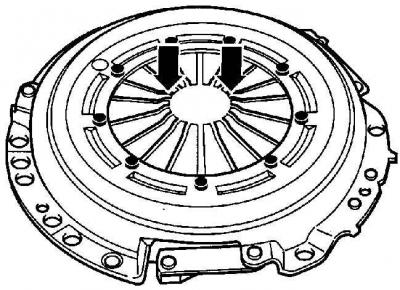

1. Check the condition of the clutch pressure plate (checkpoints are indicated by arrows). The traces of wear at the ends of the pressure spring should be no more than 0.3 mm.

2. Check the tightness of the spring connection between the pressure plate and the clutch drive housing. Scratches and missing or damaged rivets are not allowed.

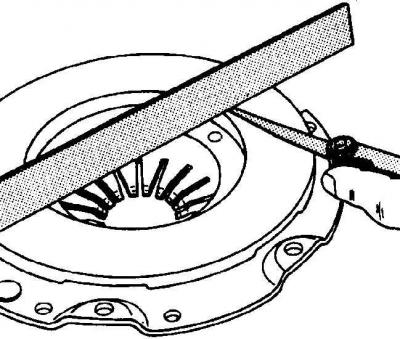

3. Check the pressure plate for cracks, burn marks and surface wear. Using a steel ruler and a feeler blade, check the flatness of the working surface of the pressure plate. The flatness of the pressure plate must not exceed 0.2 mm.

4. Check the condition of the friction surface of the flywheel for cracks, burn marks and surface wear.

5. Check the condition of the friction linings of the clutch disc and if there are traces of oil or mechanical damage on them, replace the clutch disc.

6. Measure the thickness of the clutch disc linings. If their thickness is less than acceptable or if the rivet heads are close to the working surface, replace them or the clutch disc.

7. Check the end play of the clutch disc, which at a distance of 2.5 mm from the outer diameter should be no more than 0.8 mm.

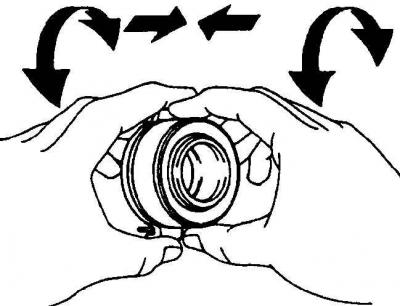

8. Check the condition of the release bearing, which should rotate easily, evenly and silently, there should be no play in it.

9. The working surface of the bearing acting on the pressure spring must be smooth, without cracks, local corrosion or wear (the arrows indicate the directions in which it is necessary to check the condition of the release bearing).

10. A faulty release bearing can be determined without removing it from the vehicle, for which it is necessary to press the clutch pedal with the engine running. If there is additional noise when you press the clutch pedal, then the release bearing is defective and needs to be replaced.

Visitor comments