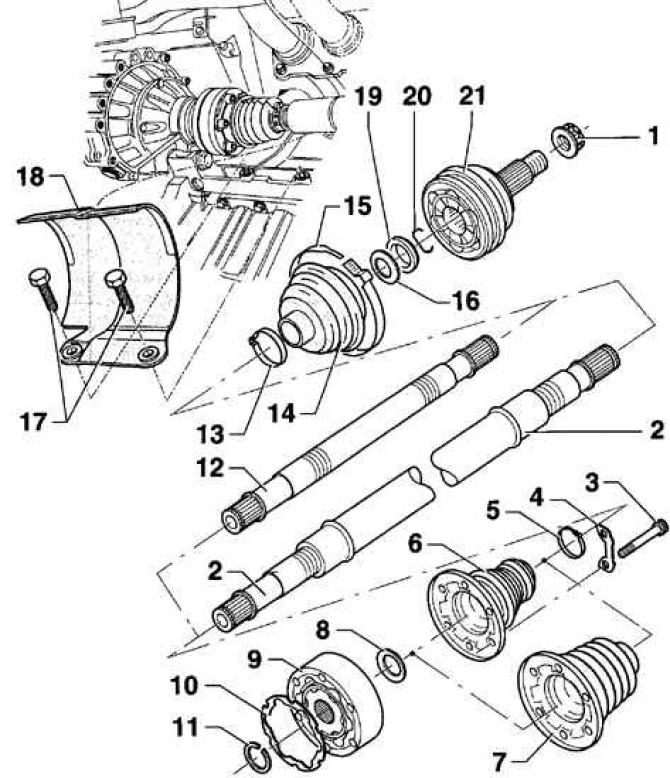

Drive shaft with constant velocity ball joint

- 1 - self-locking twelve-sided nut. At installation it is necessary to use a new nut;

- 2 - right drive shaft;

- 3 - bolt with an internal shaped recess, 40 Nm;

- 4 - plate;

- 5 - collar;

- 6 - protective cover. The inner cuff is made of plastic without ventilation holes;

- 7 - inner protective shell of the hinge. The inner cuff is made of rubber with a hole for ventilation;

- 8 - disc spring;

- 9 - inner hinge of equal angular velocities. The hinge is replaced only as an assembly;

- 10 - seal. When installing, a new seal must be used. Remove the protective film from the seal and stick the seal to the hinge;

- 11 - retaining ring;

- 12 - left drive shaft;

- 13 - collar;

- 14 - protective cover of the external hinge;

- 15 - clamp;

- 16 - disc spring;

- 17 - bolt, 35 Nm;

- 18 - protective cover;

- 19 - thrust ring;

- 20 - retaining ring;

- 21 - external constant velocity joint

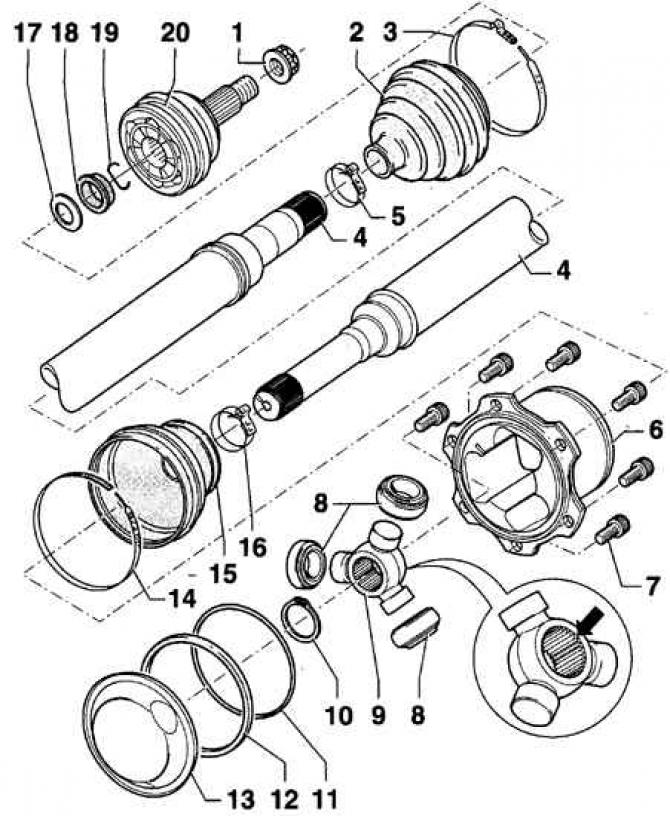

Drive shaft with three-arm joint (tripoid)

- 1 - self-locking twelve-sided nut. At installation it is necessary to use a new nut;

- 2 - protective cover of the external hinge;

- 3 - clamp;

- 4 - drive shaft;

- 5 - collar;

- 6 - hinge body;

- 7 - bolt with an internal shaped recess, 40 Nm;

- 8 - roller;

- 9 - three-arm roller holder. The chamfer on the slots of the roller holder must be directed towards the drive shaft;

- 10 - retaining ring. At installation it is necessary to use a new lock ring;

- 11 - o-ring of circular cross-section. If there is damage, a new O-ring must be used.;

- 12 - sealing ring;

- 13 - cover;

- 14 - large clamp;

- 15 - protective cover of the inner hinge;

- 16 - small clamp;

- 17 - disc spring;

- 18 - thrust ring;

- 19 - retaining ring;

- 20 - inner hinge of equal angular velocities. In case of failure, it must be replaced. When installing on the drive shaft, press the CV joint with a plastic hammer until it is fixed with a retaining ring

Warning: After removing the drive shaft from the car, do not lower the car to the ground and move it, otherwise it is easy to damage the hub bearing.

Removing

1. Raise the car and remove the front wheel.

2. Unscrew the dodecagonal nut securing the drive shaft to the hub. To keep the hub from turning when unscrewing the nut, the assistant must press the brake pedal.

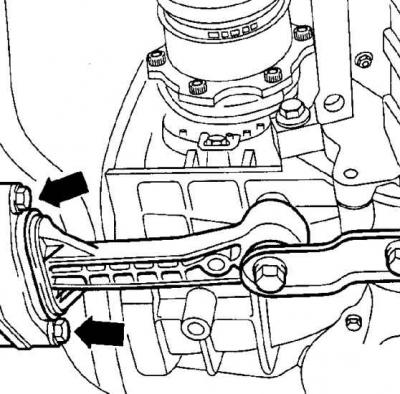

3. Remove the socket head bolts securing the drive shaft to the gearbox flange. To loosen the bolts, you can use an internal multi-tooth wrench, eg HZ 990 Lg-8.

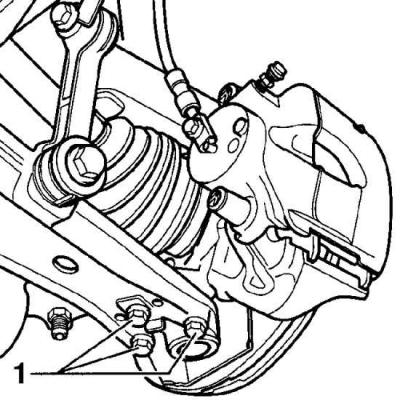

4. Using a scriber, mark the mounting position of the bolts (1), securing the front suspension lower ball joint to the wishbone. Unscrew the bolts.

5. Tilt the shock strut outward from the vehicle and remove the drive shaft from the steering knuckle.

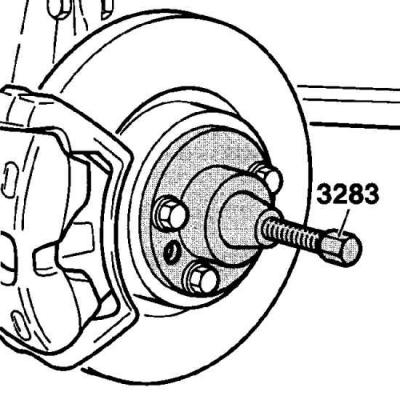

6. If the drive shaft is very tight in the hub, use the VW-3283 puller to remove it.

Vehicles with automatic transmission

7. Unscrew the two bolts securing the power unit pendulum support to the beam.

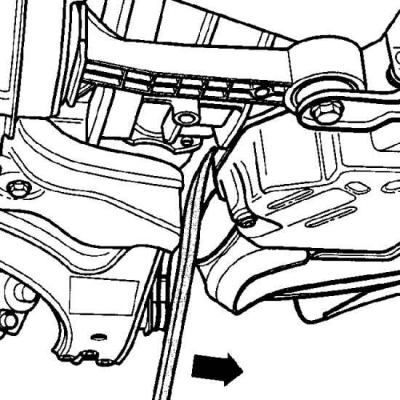

8. Insert a pry bar between the beam and the engine block and move the cylinder block forward while removing the tripod type hinge.

Installation

1. Before installing the drive shaft, clean the splines on the drive shaft and in the wheel hub.

2. Align the splines and insert the drive shaft into the wheel hub.

3. Clean the hex nut bearing surface and lubricate it with a thin film of oil.

4. Screw in new hex nuts.

5. Insert the outer joint of the drive shaft into the wheel hub as far as it will go.

6. Using new bolts, screw the lower joint of the front suspension to the transverse arm and tighten the fastening bolts to 20 Nm, then tighten them by 90°.

7. Screw the drive shaft to the gearbox flange and tighten the mounting bolts to 40 Nm.

Vehicles with automatic transmission

8. Screw in and tighten the bolts of the pendulum support of the power unit to the beam with a torque of 25 Nm.

9. Screw on the dodecagonal nut of the drive shaft and tighten it to a torque of 300 Nm. To keep the hub from turning, the assistant must press the brake pedal.

10. Loosen the hex nut one turn.

11. Tighten the dodecagonal nut to 50 Nm, then tighten by 30°.

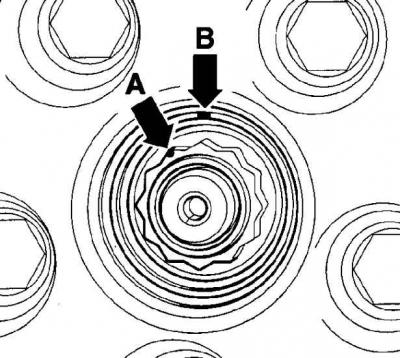

12. To turn a hex nut 30°further, apply one mark on the teeth of the nut (arrow A), and the second mark on the hub opposite the adjacent tooth (arrow B) and, turning the nut, align the marks.

13. Install the front wheels, then lower the vehicle and tighten the wheel nuts.

14. Install the wheel trim.

Visitor comments