Attention! The CV joint drive shafts VL 90 and VL 100 have an identical design.

Attention! Drive shafts with internal CV joint «tripod» AAR 3300i have an identical design.

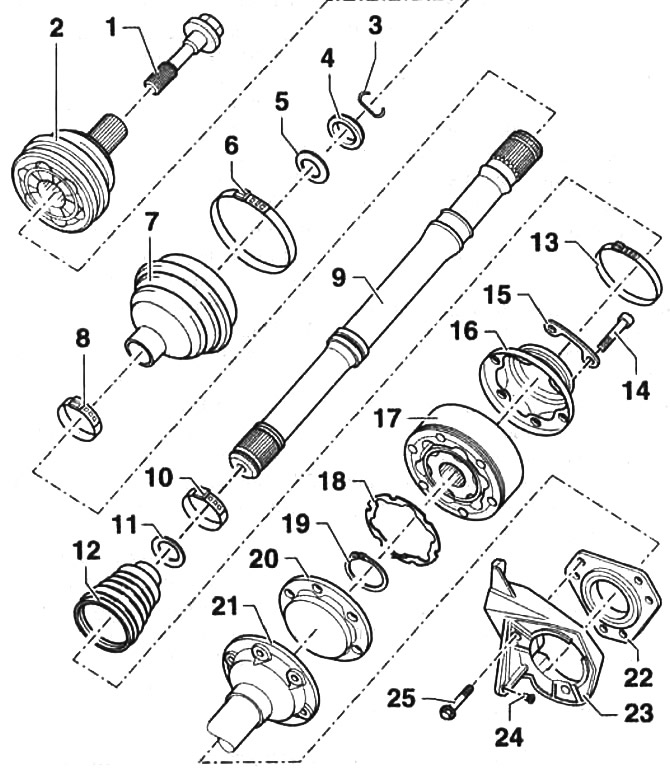

6.0. Drive shaft with constant velocity joint VL 107

1 - hub bolt*. The bolt is self-locking. Its pre-tightening is carried out with a force of 200 Nm, and then the bolt must be tightened by 180°

2 - outer CV joint. Replaced as a set

3 - retaining ring. Inserted into a groove on the shaft

4 - thrust ring. The larger ring diameter must face the Belleville spring when installed

5 - poppet (disk) spring. The larger diameter of the spring must face the CV joint

6 - clamping collar on the landing belt of large diameter *

7 - cuff of the outer CV joint. When installing, inspect the cuff for damage

8 - clamping collar on the landing belt of small diameter *

9 - half shaft

10 - clamping collar on the landing belt of small diameter *

11 - poppet (disk) spring. The larger diameter of the spring must face the CV joint

12 - cuff of the inner CV joint. When installing, inspect the cuff for damage

13 - clamping collar on the landing belt of large diameter *

14 - bolt. First, it should be tightened with a force of 10 Nm. The final tightening is carried out with a force of 40 Nm for M8 bolts and 70 Nm for M10 bolts

15 - gasket

16 - CV joint housing cover. The lid is knocked down with a punch. When installing the cover, its inner surface should be lubricated with sealing mass (sealant). The surfaces to be bonded must be cleaned and degreased.

17 - inner CV joint. Replaced as a set

18 - sealing gasket. The surfaces to be bonded must be cleaned and degreased.

19 - retaining ring*. Inserted into a groove on the shaft

20 - cover*. Only available for CV joints VL100/107. Breaks down with a punch.

21 - intermediate shaft

22 - supporting bearing of the intermediate shaft. It is located on the right side of the gearbox. Only for shafts with CV joints VL107. Can be removed from the intermediate shaft using a suitable puller

23 - intermediate shaft support bracket. Only for shafts with CV joints VL107

24 - three bolts for securing the intermediate shaft support. Pre-tightening 5 Nm, final tightening 35 Nm

25 - three bolts for securing the intermediate shaft. Tightening torque 20 Nm

* to be replaced after dismantling

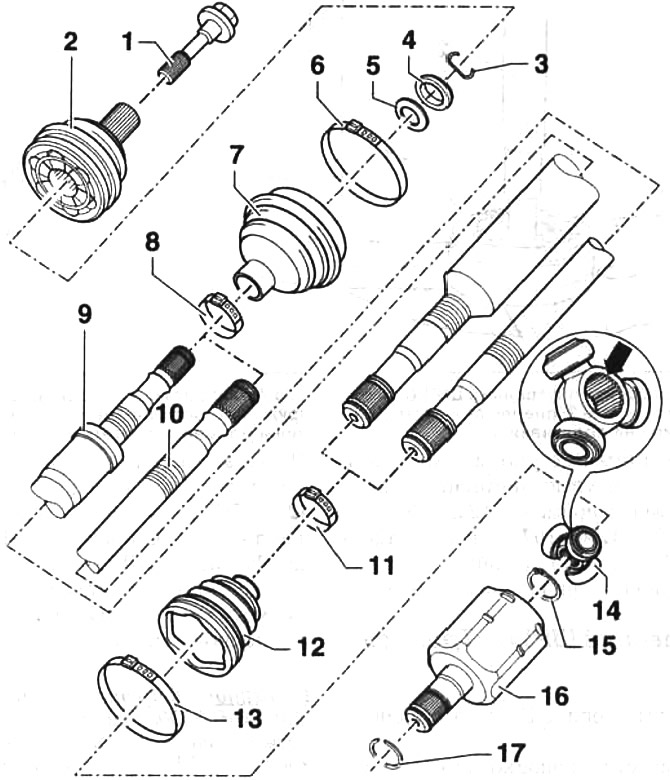

6.0a. Drive shaft with internal constant velocity joint «tripod» AAR 26001

1 - hub bolt*. The bolt is self-locking. It is pre-tightened with a force of 200 Nm. and then the bolt should be tightened by 180°

2 - outer CV joint. Replaced as a set

3 - retaining ring. Inserted into a groove on the shaft

4 - thrust ring. The larger ring diameter must face the Belleville spring when installed

5 - poppet (disk) spring. The larger diameter of the spring must face the CV joint

6 - clamping collar on the landing belt of large diameter *

7 - cuff of the outer CV joint. When installing, inspect the cuff for damage

8 - clamping collar on the landing belt of small diameter *

9 - right half shaft

10 - left half shaft

11 - clamping collar on the landing belt of small diameter *

12 - cuff of the inner CV joint. When installing, inspect the cuff for damage

13 - clamping yoke on the landing belt of large diameter '

14 - clutch with a roller. The coupling is installed on the splines of the drive shaft with a chamfered side

15 - retaining ring. Inserted into a groove on the shaft

16 - hinge body «Tripod». Only CV joint AAR 2600i. The CV joints of the right and left drive shafts are inserted into the splined holes in the gearbox. CV joint AAR 3300i of the right shaft is connected to the intermediate shaft, and the left - to the flange on the gearbox

17 - retaining ring. Inserted into a groove on the shaft

* to be replaced after dismantling

Visitor comments