Due to the fact that a VW scan tool is needed to obtain an accurate oil temperature (tester), then this work is recommended to be entrusted to the workshop.

The transmission oil level in the automatic transmission is checked and topped up only as part of maintenance.

A sufficient amount of gear oil in the gearbox is essential for the normal functioning of the automatic transmission.

With a low oil level, as well as with an overestimated one, the performance of the automatic transmission is reduced.

Required fixtures and tools:

- butter dish;

- protective glasses;

- container for collecting gear oil;

- instrument for measuring oil temperature.

Required consumables:

- transmission oil VW specification G 052 025;

- sealing ring for the threaded plug of the filler hole;

- protective cap for the threaded filler plug.

Attention! Do not start the engine if oil is drained from the automatic transmission. The car cannot be towed if there is no oil in the box.

When performing all work, carefully observe cleanliness.

The slightest contamination that has entered the automatic transmission can cause it to fail.

Checking the oil level

Attention! The transmission oil temperature must be less than +30°C or less before checking the level. This oil temperature is reached almost immediately after starting the engine. Volkswagen car repair shops use a diagnostic tool to monitor oil temperature, which is connected to the diagnostic socket on the car. Without a diagnostic tool, the transmission oil temperature can only be determined approximately.

Attention! Transmission oil may escape during work. Wear safety goggles.

1. Make sure that the transmission control unit has not entered into an emergency program.

2. Move the automatic transmission control lever to position P, and turn off the air conditioner and heater.

Attention! Jacking up a vehicle or placing it on jack stands is dangerous. Therefore, it is recommended that you familiarize yourself with the safety precautions outlined in chapter «car jacking».

3. Park the vehicle horizontally on jack stands.

4. Start the engine and leave it to idle.

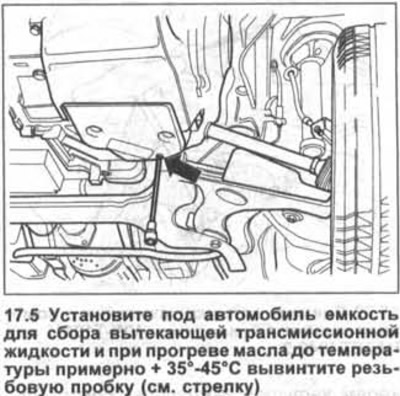

5. Place a container under the car to collect the leaking transmission fluid and, when the oil warms up to a temperature of approximately + 35°-45°C, unscrew the screw plug (see arrow in illustration). In this case, the transmission oil accumulated in the bypass tube will flow out.

If the gear oil level is normal, then at a temperature of approximately +35°...45°C, it will begin to flow out of the bypass tube in the form of drops.

As the oil temperature rises, approximately one drop per second should flow out. In this case, it is not necessary to replenish the volume of the transmission small.

Screw in the screw plug with a new O-ring and tighten it to 15 Nm. The old sealing ring on the plug must be cut with side cutters and removed.

If, when the transmission oil is heated to the temperatures indicated above, it does not flow out through the bypass tube or almost does not flow out, then the oil volume in the gearbox should be replenished.

To do this, screw the plug with the old sealing ring tightly by hand and immediately turn off the engine so that the transmission oil does not heat up unnecessarily.

Gear oil filling

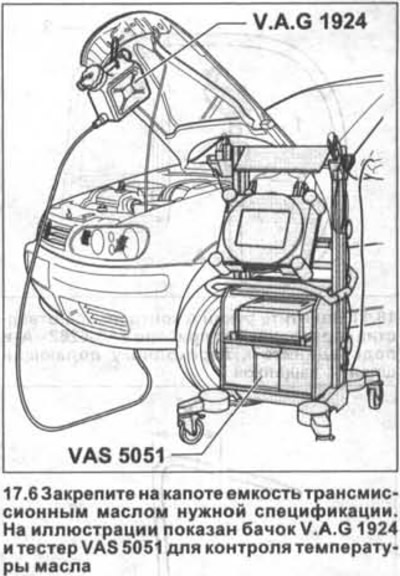

6. Attach a container to the hood with gear oil of the correct specification (see illustration).

7. Remove the vacuum pump along with the bracket to provide access to the oil filler neck. Place the vacuum pump with the bracket away from the place of work so that it does not get into the impeller of the radiator blower fan.

8. Remove the safety cap from the filler plug by prying it with a screwdriver (see illustration). The cap is damaged in this case and therefore it should be replaced with a new one. The cap secures the fit of the cork.

9. Remove the plug from the filler neck.

10. Insert the tube of the VAG 1924 filling container into the filler neck and fill in the transmission fluid (see illustration). Fill with liquid until it starts to flow out of the control hole (bypass tube).

11. Screw plug 1, replacing its old sealing ring with a new one, into the control hole (bypass tube) and tighten the plug with 15 Nm (see arrow in illustration).

12. Turn off the ignition and disconnect, if used, the diagnostic tester.

13. Install plug 3 on the filler hole, put on it the safety cap4 (see illustration 17.11) and fix the stopper.

Attention! The safety cap must be replaced without fail, because it locks the plug.

14. Reinstall the vacuum pump bracket over the filler neck.

15. Lower the car on wheels.

Visitor comments