As part of maintenance, only the condition of the ribbed belt should be checked and, if damaged, replaced with a new one.

Special tools and fixtures are not required.

To replace a worn or damaged belt, you will need a ribbed belt that matches the type of engine installed in your vehicle.

Examination

1. Engage neutral gear.

Attention! There is a risk of injury when the vehicle is jacked up or placed on jack stands. Familiarize yourself with the safety precautions outlined in the chapter «car jacking».

2. Jack up the vehicle and place it on jack stands.

3. Chalk on the belt 1 mark in the form of a transverse line (see illustration).

4. Turn the engine in the direction of its rotation, acting from under the car. To do this, install the socket head on the bolt of the belt pulley.

Rotate the motor clockwise until the belt has completed a full turn and the chalk mark is visible.

While turning the motor, carefully inspect the belt to check its condition.

This check should reveal the absence or presence of the following damage to the ribbed belt:

- traces of oil and grease;

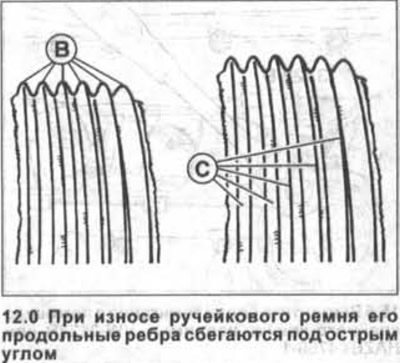

- belt wear. When the belt is worn, its longitudinal ribs converge at an acute angle (see B in Figure 12.0). The ribs of the new belt are trapezoidal in shape. The ribs of the belt move away from the cord and it is noticeable due to the lighter color (see C in Figure 12.0);

- hardened or glassy edges.

Other damage to the ribbed belt are:

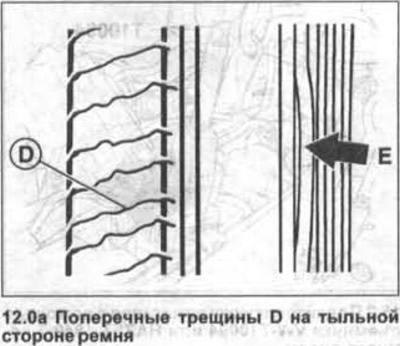

- A) transverse cracks D on the back of the belt (see illustration 12.0a);

- b) detachment of the E part of the ribs (see arrow in illustration 12.0a);

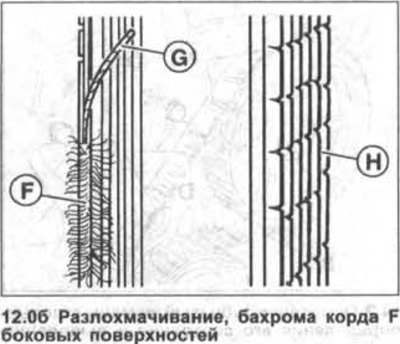

- V) fraying, F cord fringe on side surfaces (see illustration 12.0b);

- G) cord breaks G (see illustration 12.0b);

- d) transverse cracks H on several ribs (see illustration 12.0b),

- e) broken belt ribs;

- and) transverse cracks on the ribs;

- h) deposits (stones) between the ribs of the belt;

- And) rolling of the belt base rubber.

If there is at least one or more of the above damages, the ribbed belt must be replaced, see the relevant chapter.

Visitor comments