Coolant circulation

To cool the engine, the coolant constantly circulates in the circuit, pumped by the water pump. While the engine is not warmed up, the coolant circulates only in the cylinder head, in the cylinder block and in the heater core.

As the temperature rises, the liquid-cooling thermostat opens a large circuit and directs coolant flow to the radiator.

The coolant moves through the radiator, while being cooled by air passing near the radiator fins.

For additional cooling of the liquid, a radiator fan is installed, driven by an electric motor. The electric fan turns on and off depending on the temperature of the coolant (see illustration 1.0).

Attention! The electric fan, under the influence of heat accumulated in the engine compartment, can automatically turn on even when the ignition is off. Before working in the engine compartment, especially near the radiator fan, it is recommended to disconnect the electric fan power plug.

Attention! When working on the cooling system, do not allow coolant to get on the timing belt. Ethylene glycol, which is part of the coolant, can damage the belt base so much that it breaks after a while. This, in turn, is fraught with serious engine damage.

Attention! During installation, the cooling system hoses must be laid without tension, and they must not come into contact with adjacent parts and assemblies. If the ends of the pipelines and hoses of the cooling system are marked or have arrows on them, then the marks or arrows at the connecting joint must be located opposite each other.

Double cooling system. Vehicles with 1.4-/1.6-litre FSI petrol engine

The FSI petrol engine has a dual-circuit cooling system that provides separate circulation of coolant with different temperatures through the cooling jacket of the cylinder block and the cylinder head.

The coolant flow is controlled by two thermostats, one of which controls the cylinder block cooling circuit and the other controls the cylinder head cooling circuit.

The advantages of a dual-circuit cooling system are:

- accelerated heating of the cylinder block, since the coolant remains in the cooling jacket of the block until it reaches a temperature of + 105°C;

- a higher temperature of the cylinder block reduces the friction of the connecting rod and crank mechanism;

- better cooling of the combustion chambers is ensured due to the lower temperature in the cylinder head.

Control of the cooling system on vehicles with a 2.0 liter FSI engine

The control elements of the cooling system are a distribution block with a thermostat, a thermostat heater, as well as springs for mechanically closing holes in the coolant circulation channels.

The coolant temperature is maintained by the engine control unit (microprocessor) with an electrically heated thermostat.

The control unit contains parametric data covering all possible situations of engine operation, and the unit selects the parameter that best suits the current operating load on the engine.

If, for example, the load on the engine is such that the electric heater of the thermostat spring is switched on, then in this case there is an additional extension of the spring and, accordingly, the thermostat stroke increases.

'This in turn leads to a decrease in the temperature of the coolant and cooling of the combustion chambers. Cooler combustion chambers provide an earlier ignition angle, which increases engine torque.

Coolant

The cooling system is filled all year round with a mixture of water, antifreeze and anti-corrosion agent. This mixture protects against damage caused by freezing, corrosion, lime deposits and, in addition, increases the boiling point of the coolant.

In the cooling circuit, when the liquid is heated, as a result of its expansion, excess pressure arises, which also contributes to an increase in the boiling point of the coolant.

Due to the heating of the coolant and its expansion, pressure is formed in the cooling system, which also contributes to an increase in the boiling point of the coolant.

The pressure in the system is regulated by a valve installed on the cap of the expansion tank. The valve opens at a pressure of 1.4-1.6 bar. A high boiling point of the coolant is necessary for the perfect operation of the engine cooling system.

Too low a boiling point of the fluid can lead to heat lock, which impedes the circulation of the coolant and impairs engine cooling. For this reason, the cooling system must always be filled with a mixture of cooling concentrate throughout the year.

When filling or changing the coolant, use purple G12 Plus antifreeze (full designation G 012 A8F) or otherwise, if it meets the technical requirements «TL VW 774F», e.g. Glysantin-Alu-Protect-Premium/G30.

Attention! To top up the coolant, even during warmer months, use only a mixture of lime blossom G12 Plus antifreeze and clean water with a low lime content. Even in summer, the proportion of antifreeze in the coolant should not be less than 40%. For this reason, when pouring water into the cooling system, add antifreeze immediately.

In our latitudes, the concentration of the coolant should provide protection against freezing at temperatures down to about -25°, and even better - up to -35°. The content of antifreeze in the coolant should not exceed 60%.

With this percentage of antifreeze and water, frost protection is provided at temperatures down to -40°C. This ratio should not be exceeded, because with an increase in the antifreeze content, the frost resistance of the coolant decreases, as well as its cooling capacity.

Attention! Refueling volumes, depending on the vehicle equipment, may differ from the values given in the table.

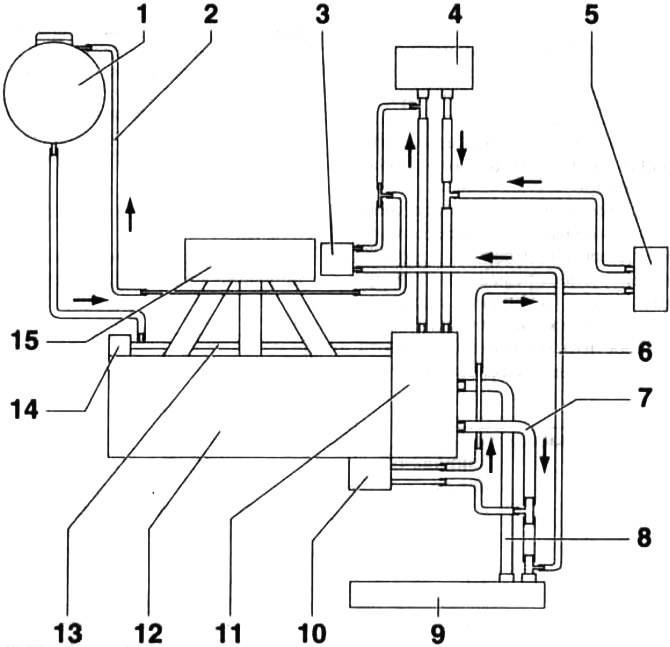

Coolant circulation. Vehicles with 1.4-/1.6-litre FSI petrol engine, 66/85 kW (90/115 hp.)

1 - expansion tank

2 - hose of the cooling system. From the recirculation valve

3 - recirculation valve

4 - heater radiator water pump / thermostat

5 - transmission oil cooling radiator Only for cars with automatic transmission

6 - cooling system hose. To recirculation valve

7 - upper hose of the cooling system

8 - lower hose of the cooling system

9 - radiator

10 - oil cooler. Only vehicles with 1.6 liter engine

11 - thermostat housing

12- cylinder head/cylinder block

13 - pipeline of the cooling system

14 - water pump

15 - intake manifold

Visitor comments