Rocker rollers on needle bearings provide a soft transmission of the stroke of the shaft cams to the valves. Hydraulic tappets under the rocker arms equalize the valve clearance.

The intake camshaft is driven by the crankshaft via a toothed belt.

This camshaft in turn drives the exhaust camshaft via a separate toothed belt (see illustration 3.0).

The aluminum cylinder block contains non-removable cast iron cylinder liners. At the bottom of the cylinder block is a crankshaft mounted on five bearings. Bolts of fastening of support of a cranked shaft cannot be unscrewed. Otherwise, you will have to change the entire cylinder block along with the crankshaft to a new one.

The water pump is located at the front of the cylinder block and is driven by two toothed belts.

The oil pump is driven through a gear from the crankshaft.

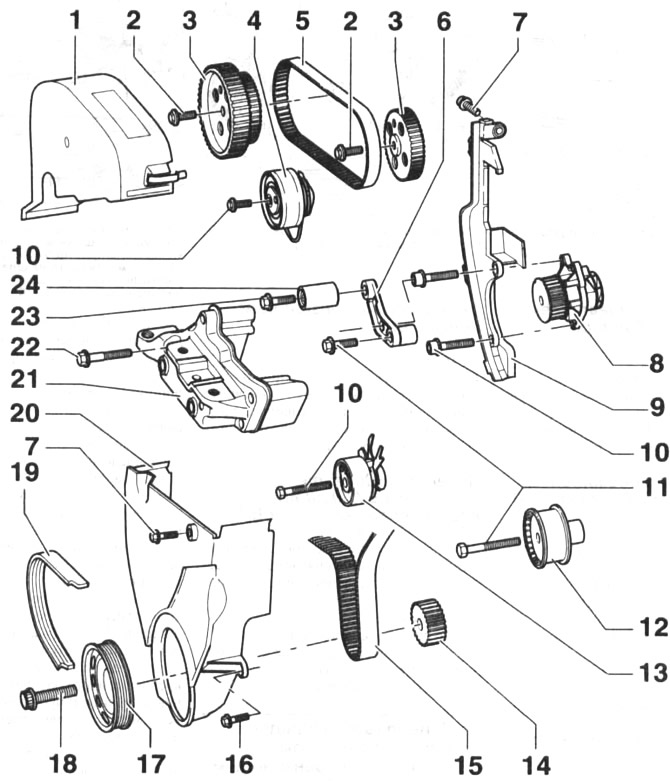

3.0 Timing gear drive. Cars with a 1.4 liter petrol engine with a power of 55 kW (75 hp.) BCA

1 - the upper part of the protective cover of the gas distribution mechanism

2 - bolt. Tightening torque 20 Nm + 90°turn (1/4 turn). The bolt should be replaced with a new one after each dismantling. To unscrew and tighten the bolt, a VW-T10016 head is required

3 - camshaft gear. The alignment hole on the gear must match the dowel pin hole on the camshaft flange

4 - tension roller for the timing belt of the exhaust camshaft drive

5 - toothed belt for the exhaust camshaft drive. Before removing the belt, mark the direction of its rotation, check the condition. Belt bending is not allowed

6 - bracket

7 - bolt. Tightening torque 10 Nm

8 - water pump. If damaged or leaking, the pump must be replaced as a set.

9 - rear cover of the gas distribution mechanism drive

10 - bolt. Tightening torque 20 Nm

11 - bolt. Tightening torque 50 Nm

12 - timing belt guide roller

13 - timing belt tension roller

14 - the drive gear of the toothed belt on the crankshaft. When the piston of cylinder No. 1 is at TDC, the turned tooth must match the reference mark on the oil pump housing

15 - toothed timing belt. Before removing the belt, mark the direction of rotation. Check the condition of the belt. The bending of the belt is not allowed.

16 - bolt. Tightening torque 12Nm

17 - crankshaft belt pulley

18 - bolt.

Attention! Two different bolts can be used. After dismantling, the bolt must be replaced with a new one. The mating surfaces of the pulley and head must be degreased. Before screwing in the bolt, its threads should be lubricated with oil.

Tightening torques:

- old-style bolt with a massive head 90 Nm + 90°turn (1/4 turn)

- new type drilled bolt 150 Nm + 180°turn (1/2 turn)

Bolt tightening can be done in several steps. The desired angle of rotation can be controlled using a conventional protractor, for example, HAZET 6690

19 - ribbed belt. Before removing the belt, mark the direction of rotation. Check the condition of the belt. The bending of the belt is not allowed.

20 - lower part of the cover of the gas distribution mechanism

21 - engine mount bracket

22 - bolt. Tightening torque 50 Nm

23 - bolt. Tightening torque 25 Nm

24 - guide roller

Visitor comments