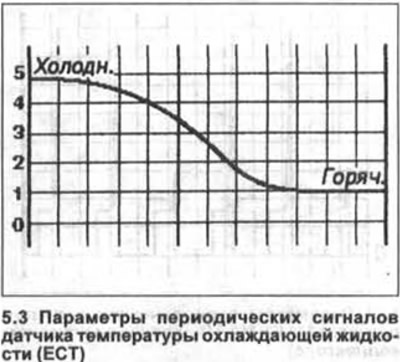

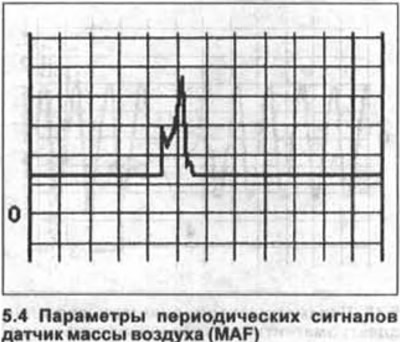

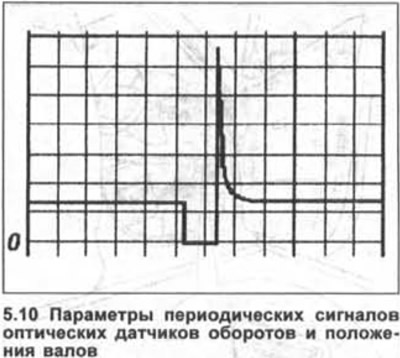

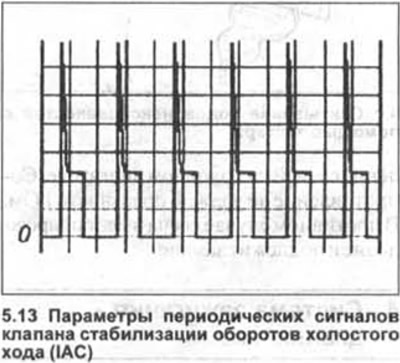

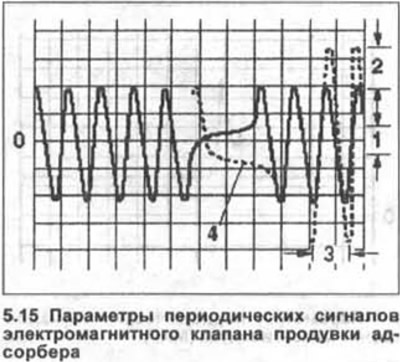

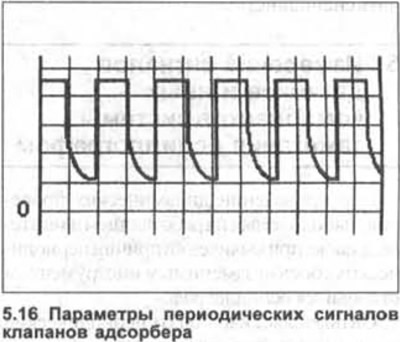

It allows you to observe periodic signals and measure the characteristics of rectangular pulses, as well as the levels of slowly varying voltages (see illustrations 5.0-5.20).

Modern oscilloscopes are usually equipped with two signal wires with a variety of probes that allow you to connect the instrument to almost any device.

The red wire is attached to the positive pole of the oscilloscope and is usually connected to the control unit terminal. The black wire must be connected to a reliable «mass (-).

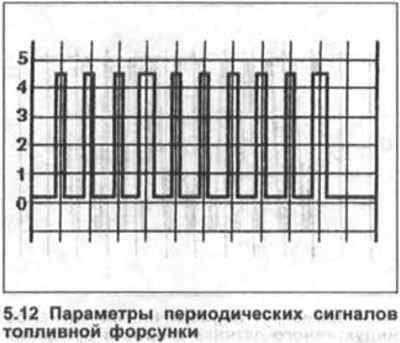

The management of the composition of the air-fuel mixture in modern automotive electronic fuel injection systems is carried out by timely adjustment of the duration of the opening of electromagnetic injectors.

The opening period of the injectors is determined by the duration of the electrical impulses generated by the control unit and supplied to the injectors. The duration of the pulses usually does not go beyond the range of 1+14 ms. A typical oscillogram of the pulse that controls the operation of the injector is shown in illustration 5.12.

Often, a series of short pulsations can also be observed on the oscillogram, following immediately after the initiating negative rectangular pulse and keeping the nozzle open, as well as a sharp positive voltage surge accompanying the closing of the nozzle.

The operation of the engine control unit can be easily checked using an oscilloscope by visually observing changes in the shape of the control signal when the engine loads change. So, the duration of the pulses when the engine is running at idle should be slightly higher than when running at low speeds. An increase in engine speed should be accompanied by a corresponding increase in the time the injectors stay open.

This dependence is especially well manifested when opening the throttle with short presses on the accelerator pedal.

1. Connect the red wire probe of the oscilloscope to the injection terminal of the control unit.

Ground the probe of the second black oscilloscope wire securely.

2. Analyze the waveform read by the oscilloscope when the engine crankshaft rotates.

3. Start the engine and check the shape of the control signal at idle.

4. Increase engine speed to 3000 rpm.

The duration of the control pulses should increase noticeably, and then stabilize at a level slightly less than or equal to the idle speed level.

Closing the throttle quickly should cause the waveform to straighten out, confirming that the injectors are closing.

When starting a cold engine, it needs some enrichment of the air-fuel mixture, which is ensured by increasing the injectors in the open position.

As the duration of the control pulses on the oscillogram warms up, it should continuously decrease, gradually approaching the value typical for idle speeds.

In injection systems that do not use a cold start aid, additional control pulses are used, which appear on the oscillogram as variable length pulsations.

The table below shows a typical dependence of the duration of the control pulses for opening the injectors on the operating state of the engine.

| Engine condition | Control pulse duration, ms |

| idle | 1-6 |

| 2000-3000 rpm | 1-6 |

| Full throttle | 6-35 |

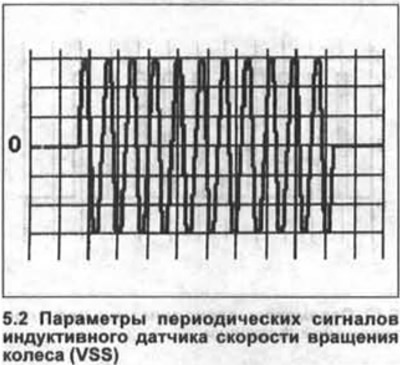

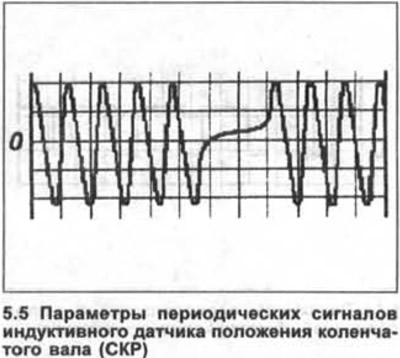

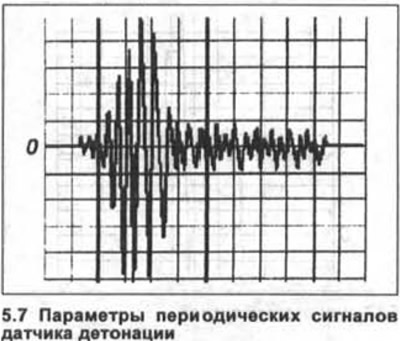

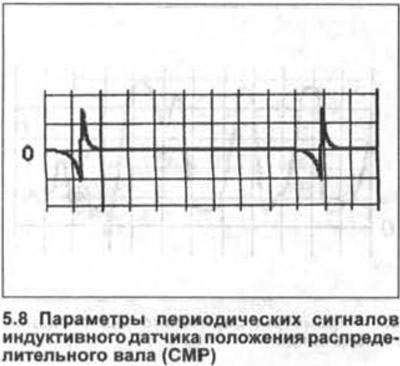

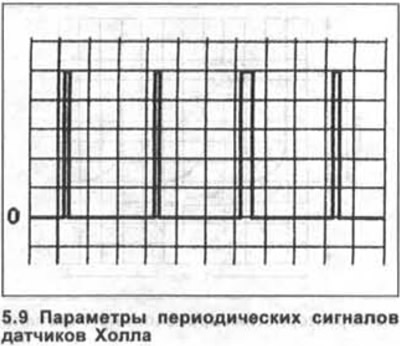

Inductive sensors

5. Start the engine and compare the oscillogram taken from the output of the inductive sensor with the reference one shown in the illustration.

An increase in engine speed should be accompanied by an increase in the amplitude of the pulse signal generated by the sensor.

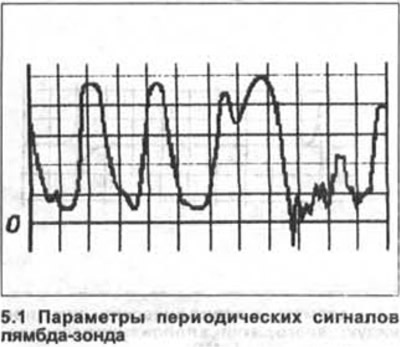

Lambda probe (oxygen sensor)

Attention! Oscillograms are given that are typical for the most commonly used zirconium-type lambda probes in cars, which do not use a reference voltage of 0.5 V. Recently, titanium probes have become increasingly popular, the operating signal range of which is 0 + 5 V, and a high level voltage is produced during the combustion of a lean mixture, and low - enriched.

6. Connect the oscilloscope to the lambda probe terminal on the control unit and to «mass» (-).

7. Make sure the engine is up to operating temperature.

8. Compare the oscillogram displayed on the screen of the meter with the reference one shown in the illustration. If the recorded signal is not wavy, but is a line, then, depending on the voltage level, this indicates excessive over-depletion (0+0.15 V), or reenrichment (0.6+1 V) air-fuel mixture.

If there is a normal waveform at idle, try depressing the accelerator pedal hard several times.

Signal fluctuations should not go beyond the range of 0 + 1 V.

An increase in engine speed should be accompanied by an increase in signal amplitude, a decrease - by a decrease.

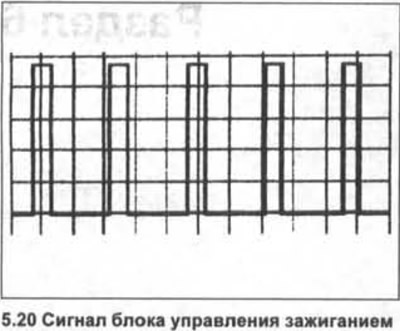

Ignition output

9. Connect the oscilloscope to the ignition block terminal on the engine control unit and «mass» (-).

10. Warm up the engine to operating temperature and leave it to idle.

On the screen of the oscilloscope, rectangular DC pulses should appear in sequence.

Compare the waveform of the received signal with the reference (see illustration).

With an increase in engine speed, the frequency of the signal should increase in direct proportion.

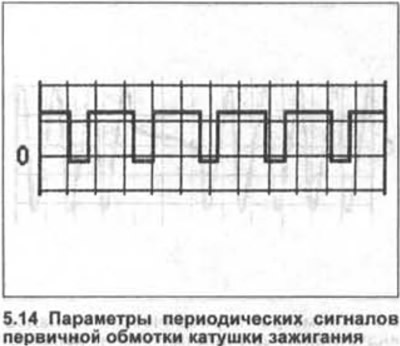

Primary winding of the ignition coil

11. Connect the oscilloscope to the ignition coil terminal and «mass» (-).

12. Warm up the engine to operating temperature and leave it to idle.

13. Compare the shape of the received signal with the reference one in the illustration. Positive voltage spikes should have a constant amplitude.

Uneven spikes can be caused by excessive secondary resistance, as well as a faulty coil wire.

Visitor comments