2. Remove the transmission pan and oil pickup.

3. Mark the mounting position of all sensors and solenoid valves, as well as the corresponding wiring (see illustration).

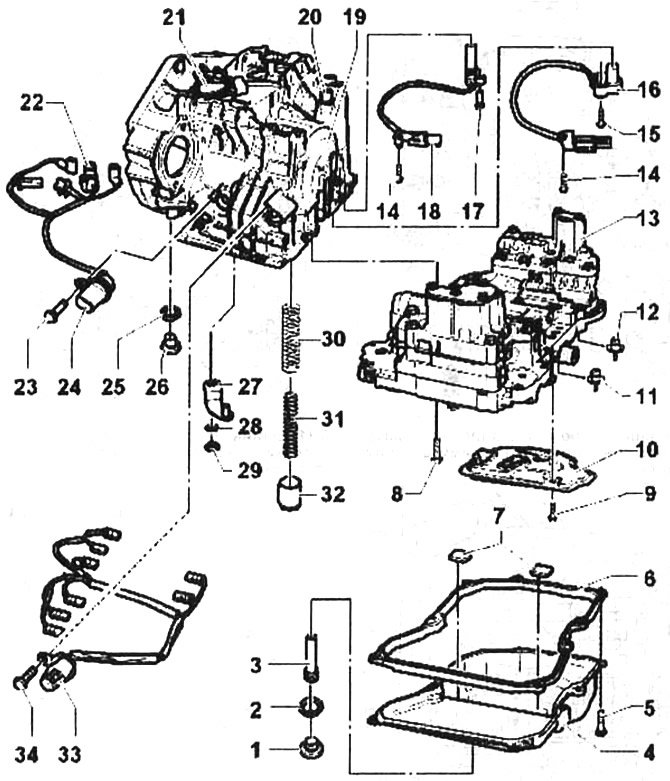

5.3. valve body

1 - plug of the transmission oil level control hole. Tightening torque 27 Nm

2 - sealing ring. To be replaced after each disassembly

3 - bypass tube

4 - pallet

5 - bolt. Tightening torque 7 Nm

6 - gasket. To be replaced after each disassembly

7 - magnets

8 - bolts, 12 pcs Tightening torque 8 Nm + 90°turn. Bolts must be replaced after each disassembly

9 - bolts, 3 pcs. Tightening torque 11 Nm

10 - oil intake

11-12 - transmission oil pressure sensors

13 - valve body

14 - bolt. Tightening torque 7 Nm

15 - bolt. Tightening torque 6 Nm

16 - input shaft speed sensor

17 - bolt. Tightening torque 7 Nm

18 - output shaft speed sensor

19 - crankcase

20 - breather cover

21 - multifunction switch

22 - transmission oil temperature sensor

23 - bolt. Tightening torque 6Nm

24 - harness with 8-pin plug and O-ring. The ring must be replaced after each dismantling

25 - sealing ring To be replaced after each dismantling

26 - drain plug

27 - shift shaft lever

28 - puck

29 - nut Tightening torque 10 Nm

30 - big spring

31 - small spring

32 - compression buffer

33 - harness with 14-pin plug and O-ring. The ring must be replaced after each dismantling

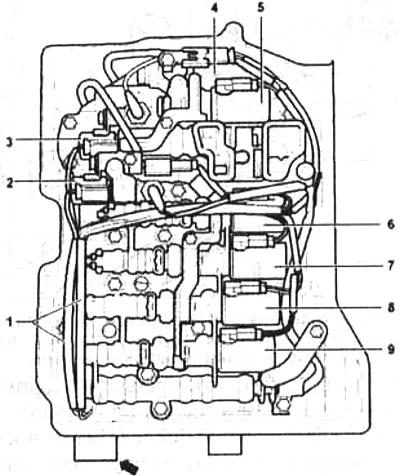

4. Use a small screwdriver to pry out the leads of the plugs of the solenoid valves 2-9 (see illustration) and disconnect the plugs.

If any plug is damaged, replace valve wiring harness with valves.

5.4. Use a small screwdriver to press the leads of the solenoid valve plugs 2-9 and disconnect the plugs

1 - harness with 14-pin plug

2 - solenoid valve 1

3 - solenoid valve 2

4 - solenoid valve 4

5 - solenoid valve 6

6 - solenoid valve 5

7 - solenoid valve 9

8 - solenoid valve 10

9 - solenoid valve 3.

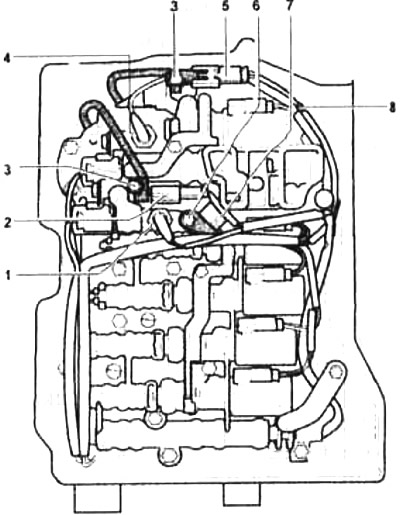

5. Disconnect plugs of gauges 1 and 2 of pressure of transmission oil (see illustration).

5.5. Disconnect plugs of gauges 1 and 2 of pressure of transmission oil

1 and 4 - transmission oil pressure sensors

2 and 5 - input / output shaft speed sensor plug

3 - bolts

6 - a bolt of fastening of the gauge of temperature of transmission oil

7 - transmission oil temperature sensor

B - wiring harness with 8-pin plug

6. Disconnect plugs 2 and 5 and unscrew screws 3 (see illustration 5.5). If any plug is damaged, replace the harness or input/output speed sensor.

7. Unscrew bolt 6, carefully remove the transmission oil temperature sensor together with the bracket from the valve body, and also release the wiring harness 8 from the holder (see illustration 5.5).

8. Remove lever 1 from the shift shaft.

In this case, hold the lever with an adjustable wrench 2 so that no force is transmitted to the multifunction switch.

Do not damage the spool valve 3 (see illustration).

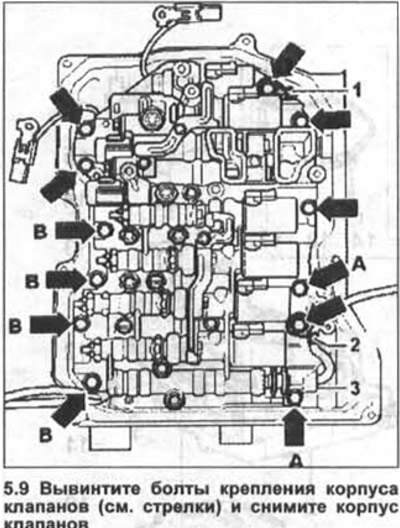

9. Unscrew the bolts of the valve body (see arrows in illustration) diagonally and carefully remove the valve body.

Arrows without designation in the illustration indicate M6x21 bolts, arrows A - M6x16 bolts, arrows B - M6x28.

10. Fix the compression buffer so that it does not fall out or remove it together with both springs.

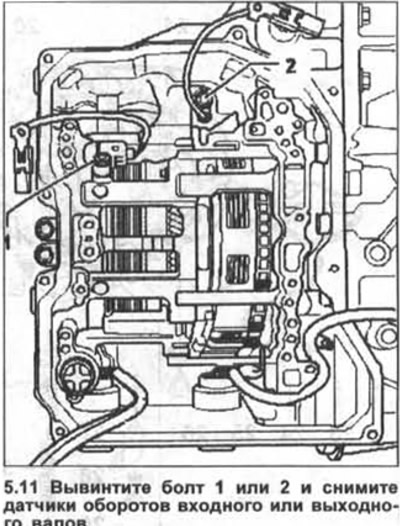

11. Unscrew bolt 1 or 2 (see illustration) and remove the input or output shaft speed sensors, if necessary.

The valve body is installed in the reverse order.

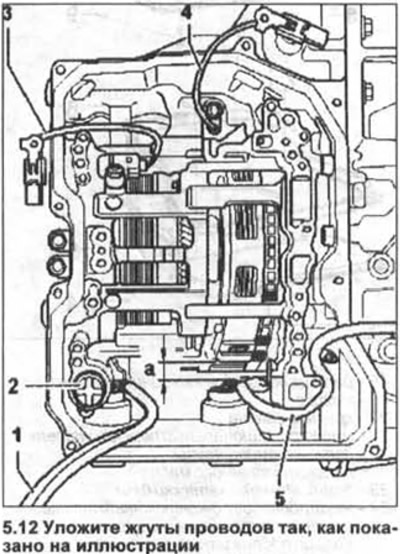

12. Route the wire harnesses as shown in the illustration so as not to pinch them.

Please note that the mounting bolts have different lengths.

After installing the valve body, fill the gearbox with transmission fluid.

13. Contact the workshop to enter the basic settings of the automatic transmission.

The procedure for removing and installing an automatic transmission is similar to removing and installing a manual transmission.

Additionally, it is required to remove the transmission oil cooler and disconnect the shift cable.

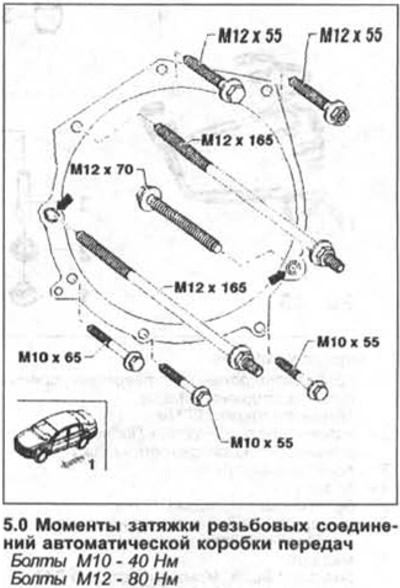

The tightening torques for threaded connections are shown in illustration 5.0.

Visitor comments