Checking the fuel level in the float chamber

The position of the float in the float chamber is not adjustable. If a malfunction is detected, check the tightness of the float and the technical condition of the needle valve, replace the defective parts.

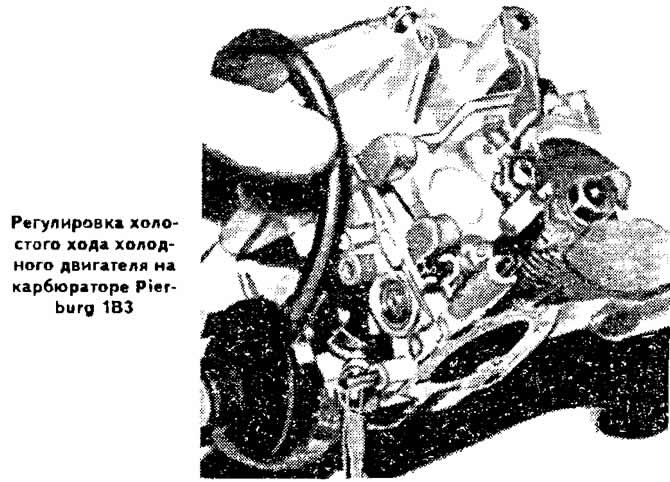

Cold idle adjustment

Warm up the engine.

Connect tachometer.

Stop engine.

Fully open the throttle valve by setting the profiled throttle slightly open cam to the appropriate position.

Start the engine without depressing the accelerator pedal.

Check the engine speed, which should be within 3500-3900 rpm.

Adjust, if necessary, the speed of the crankshaft with the throttle stop screw, which rests on the profiled cam of the throttle slightly opening.

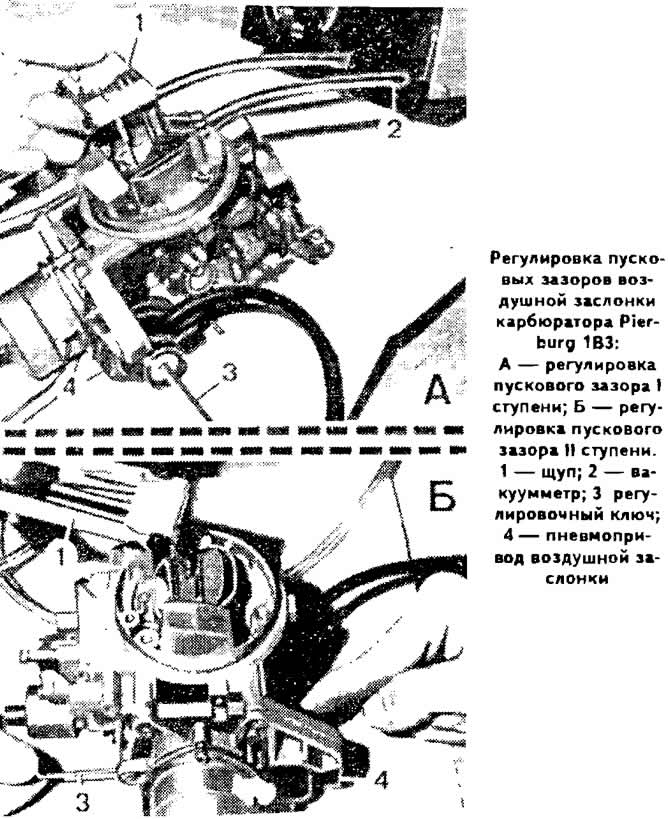

Air damper starting gap adjustment

Remove starter cover.

Fully open the throttle valve by placing the throttle valve opening cam on the corresponding profile.

Connect a vacuum gauge and a vacuum pump to the air damper actuator and create a vacuum of 100 mbar in the pneumatic actuator.

If the air damper actuator is sealed, the vacuum must not decrease by more than 5 mbar per minute and decrease to less than 40 mbar.

Bring the vacuum in the pneumatic actuator of the air damper to 200-300 mbar.

Use a set of feeler gauges to measure the starting gap of the first stage of the air damper, which for cars with a manual gearbox should be 2.0±0.15 mm, for cars with an automatic gearbox - 2.4±0.15 mm.

If necessary, set the required gap with the screw for adjusting the stroke of the pneumatic actuator diaphragm located on its cover (see photo).

Close the atmospheric opening of the air damper pneumatic actuator with a plug, create a vacuum of 200 mbar in the pneumatic actuator, which, if the pneumatic actuator is tight, must remain unchanged for at least 1 minute.

Use a set of feeler gauges to measure the starting gap of the second stage of the air damper, which on cars with a YN engine should be within 4.3±0.15 mm, on cars with a WV engine with a manual gearbox - 3.5±0.15 mm, with an automatic gearbox - 3.3 + 0.15 mm.

If necessary, set the proper clearance with the adjusting screw on the end of the air damper rod.

Throttle valve adjustment

The throttle position is adjusted at the factory, but if it is out of adjustment, it can be restored as follows:

- remove the plug of the throttle stop screw;

- connect a vacuum gauge in parallel to the vacuum ignition timing sensor of the ignition distributor;

- start and warm up the engine;

- take the throttle control sector away from the idle stop;

- screw in the throttle stop screw so that the vacuum begins to increase;

- unscrew the throttle stop screw until the minimum vacuum is obtained, then unscrew it another half a turn;

- adjust the idle speed of a warm engine, as indicated below;

- install a new plug on the throttle stop screw.

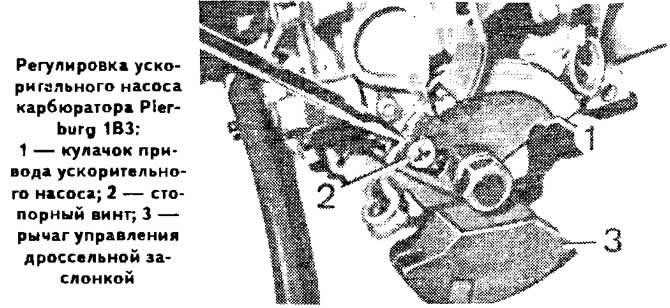

Accelerator pump adjustment

Remove carburetor.

Fill the float chamber of the carburetor with fuel and place a beaker with a funnel under the carburetor.

Move the throttle control sector away from the idle stop.

Slowly move the throttle ten times from lock to lock, spending about 3 seconds each time, thereby activating the accelerator pump.

Measure the amount of fuel in the beaker: for one cycle, the accelerator pump should supply 0.9 + 0.15 cm3 fuel.

If necessary, adjust the performance of the accelerator pump by moving the cam of the accelerator pump drive lever on the bracket, after loosening the lock screw.

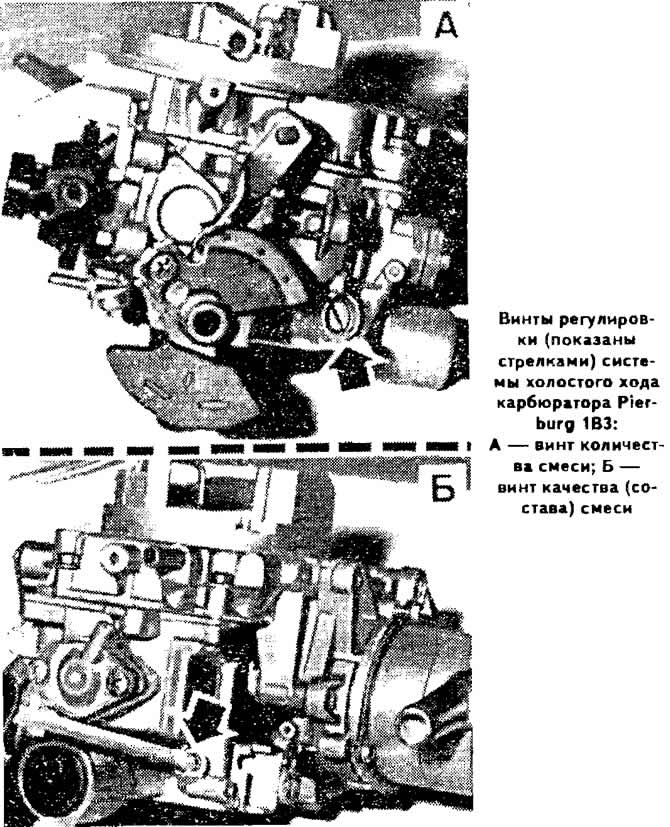

Warm engine idle adjustment

The idle speed adjustment of the engine must be carried out on a warm engine with adjusted clearances in the valve drive mechanism, with the ignition timing correctly set.

Connect the tachometer and gas analyzer in accordance with the operating instructions.

With the adjusting screw for the amount of the mixture, set the crankshaft speed within 900-1000 rpm.

Adjusting screw quality (composition) mixture to achieve carbon monoxide content (SO) in exhaust gases no more than 0.5-1.5%. Restore the crankshaft speed to 900-1000 rpm. If necessary, restore the specified CO content.

Visitor comments