Remove the bearing caps No. 5, 1 and 3 of the camshaft, then unscrew the nuts of the studs securing the bearing caps No. 2 and 4 alternately crosswise.

Remove the camshaft from the cylinder head bearings and remove the valve lifters.

Install a device for compressing valve springs or a special device VW 541 for removing and installing valve crackers on the cylinder head and, using pliers with pointed ends, release the valves from crackers, after pressing the lever of the special device.

Remove valve springs with poppets.

Remove valve stem seals and spring washers using pliers.

Take out the valves.

Clear details.

Check the degree of wear of the valve guide bushings and the clearance between the bushings and valve stems.

Insert the new valve into the guide bush so that the end of the valve stem is flush with the edge of the guide bush, and determine the gap between the valve stem and the guide bush using tool VW 387 with an indicator, resting its foot on the valve head.

Replace the guide bushings if the clearance exceeds the maximum allowable limit of 1.0 mm for intake valves and 1.3 mm for exhaust valves.

Check that the flatness of the mating surface of the cylinder head is not broken using a metal ruler and a set of feelers.

Grind, if necessary, the mating surface of the cylinder head within acceptable limits (see subsection «Design and specifications»).

Check the condition of the valves and valve springs.

Check the condition of the valve seats and grind them if necessary. Grinding is carried out with a special tool in compliance with the allowable limits (see subsection «Design and specifications»).

Grind, if necessary, the working chamfers of the intake valves. The working chamfers of the exhaust valves are not subject to grinding, grinding of the exhaust valves is allowed, in other cases they must be replaced.

Thoroughly clean the cylinder head before assembly and after grinding the valve seats and lapping the valves.

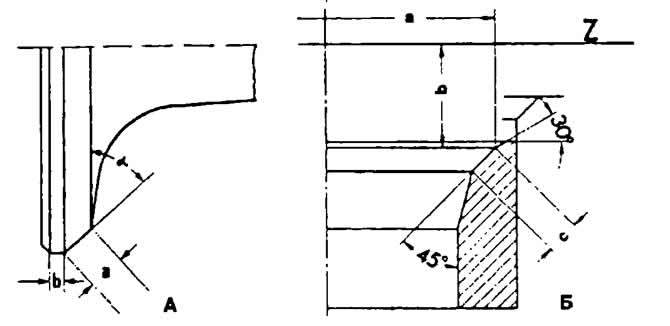

Main dimensions for grinding valves and valve seats:

A - inlet valve;

α - angle of the working chamfer (45°);

a - the width of the working chamfer;

b is the height of the edge of the valve head;

B - valve seat (inlet and outlet);

Z is the plane of the cylinder head;

a - outer diameter of the working chamfer;

b is the distance from the end face of the working chamfer of the valve to the plane of the cylinder head;

c is the width of the working chamfer of the valve seat.

Visitor comments