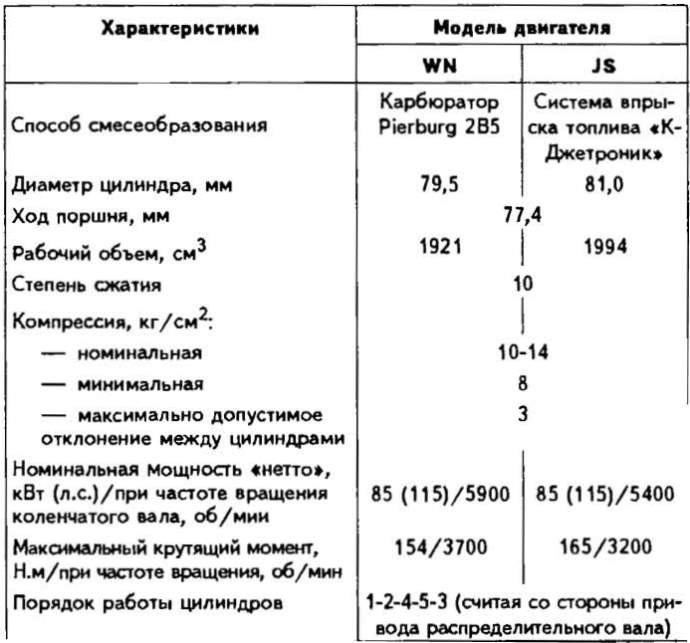

Main technical characteristics of five-cylinder engines

Cylinder head

The cylinder head is cast from aluminum alloy. Seats and valve guides are pressed into the cylinder head. There are no special inscriptions on the cylinder head gasket for orientation. Install the gasket with marks in the direction of the plane of the cylinder head.

Warping of the mating plane of the head with the cylinder block, not more than, mm: 0.1.

Permissible height of the cylinder head after grinding, not less than, mm: 132.7 5.

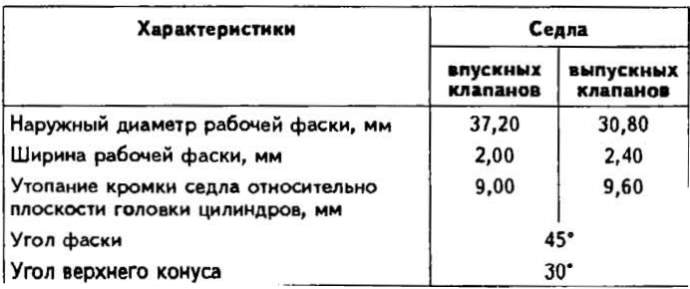

Valve seats

Valve seats are non-removable. If there are signs of burning or wear that cannot be removed by grinding, replace the cylinder head.

Valve seat specifications

Valve guides

The valve guides are made of special brass and are pressed into the cylinder head.

Maximum allowable limit clearance (when worn) between valve stem and guide sleeve (measurement procedure see page), mm:

- for inlet valves: 1.0;

- for exhaust valves: 1.3.

Hole diameter in valve guide bushings, mm: 8.013-8.035.

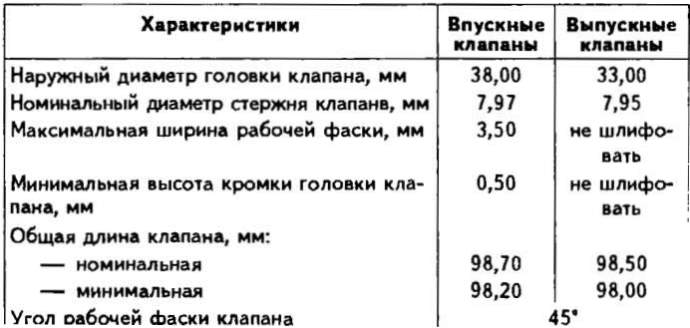

Valves

The valves are located in the cylinder head in a row and are actuated directly by the camshaft lobes through the tappets. Exhaust valves are not subject to grinding.

Valve characteristics

Clearances in the valve drive mechanism

WN engine and JS engine prior to MY 1986

The gap between the camshaft cams and shims at a coolant temperature above 35°C should be 0.25±0.05 mm for intake valves and 0.45±0.05 mm for exhaust valves, on a cold engine, respectively 0.20±0.05 and 0.40±0.05 mm.

The gap is adjusted by selecting the thickness of the shims mounted on the upper ends of the pushers. Spare parts are supplied with shims with a thickness of 3.00 to 4.25 mm at intervals of every 0.05 mm.

JS engine from MY 1986

The gaps in the valve drive mechanism are compensated automatically by hydraulic tappets.

Valve springs

Each intake and exhaust valve has two springs. The springs are the same for both intake and exhaust valves.

Pushers

The valve lifters are located directly in the cylinder head. Adjusting washers of various thicknesses are installed on the upper ends of the pushers to adjust the thermal clearances of the valves.

Visitor comments