- Warping of the mating plane of the head with the cylinder block, not more than, mm: 0.1.

- Permissible height of the cylinder head after grinding, not less than, mm: 167.30.

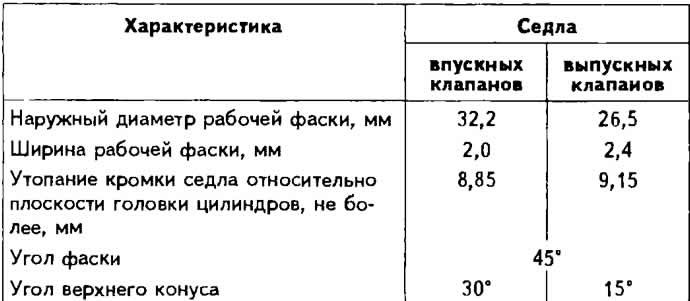

Valve seats

The valve seats are made from powder metallurgy steel and are non-replaceable. If signs of burning or wear are found that cannot be removed by grinding, replace the cylinder head.

Valve seat specifications

Valve guides

The valve guides are made of special brass and pressed into the cylinder head, which was previously heated to a temperature of 80-100°C in an oil bath or electric furnace.

Maximum allowable limit clearance (when worn) between valve stem and guide bush (measurement technique, see subsection «Dismantling and assembly of a head of cylinders»):

- for inlet valves: 1.0;

- for exhaust valves: 1.3.

Hole diameter in valve guide bushings, mm: 8.013-8.035.

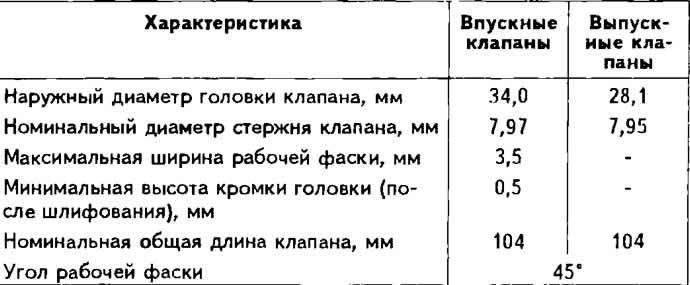

Valves

The valves are arranged in a row in the cylinder head and are actuated by the camshaft cams through levers. Exhaust valves are not subject to grinding.

Valve characteristics

Clearances in the valve drive mechanism

Normal clearance between the camshaft cam and the lever, measured with a feeler gauge, on a hot engine (coolant temperature over 35°C) is 0.20 mm for intake valves and 0.30 mm for exhaust valves; on a cold engine (after repair) - 0.15 mm for intake valves and 0.25 mm for exhaust valves.

Valve springs

Each intake and exhaust valve has one spring. The intake and exhaust valve springs are the same.

Valve levers

Steel levers. The lever rests with its spherical recess at one end on the spherical head of an adjusting bolt with a micrometric thread, designed to adjust the gaps in the valve drive mechanism. The return of the lever to the end of the valve stem and its retention on the spherical head of the adjusting bolt are provided by a lamellar steel spring.

Visitor comments