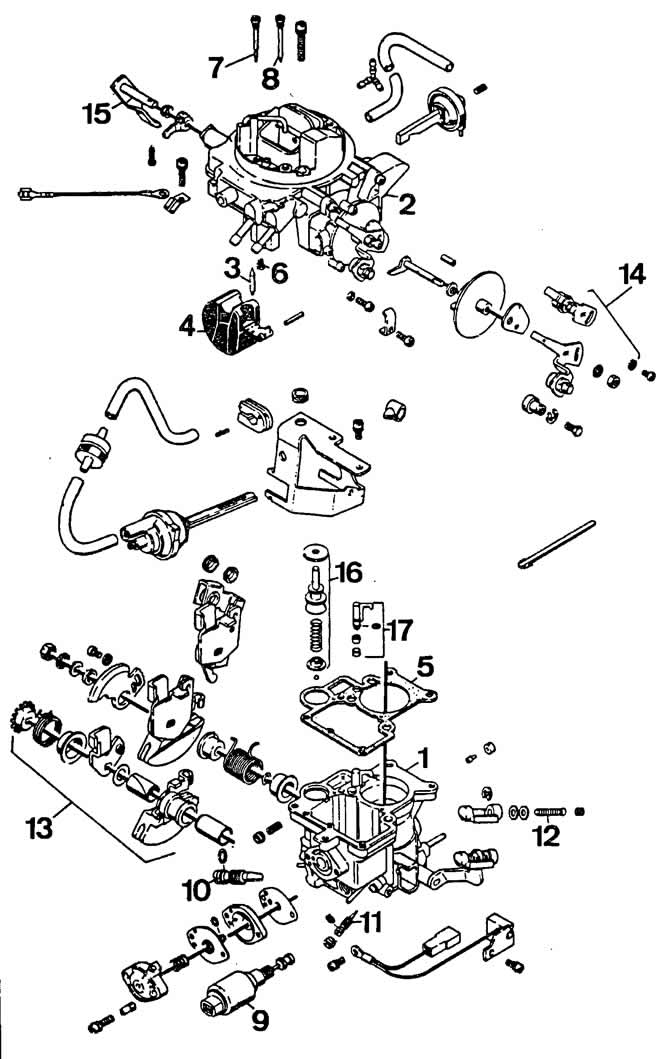

Pierburg 1B1 carburetor details:

1 - carburetor body;

2 - carburetor cover;

3 - needle valve;

4 - float;

5 - float chamber gasket;

6 - fuel jet of the main metering system;

7 - idle fuel jet;

8 — fuel jet econostat;

9 - electromagnetic shut-off valve;

10 - adjusting screw for the amount of idle mixture;

11 - quality screw (composition) idling mixtures;

12 - adjusting screw for slightly opening the throttle;

13 - throttle control levers;

14 - air damper control levers;

15 - accelerator pump drive lever;

16 - accelerator pump piston;

17 - spray accelerator pump

Carburetor adjustment

Adjusting the fuel level in the float chamber

Remove the carburetor cover.

Set the carburettor cap at a 45°angle and check the distance between the float and the plane of the float chamber, which should be 27 mm.

To adjust, bend the float arm slightly behind the needle valve fulcrum. The float must rest on the valve needle at a right angle; at the same time, the elastic pusher should not be sunk.

Air damper starting gap adjustment

Pull out the choke control knob completely. At the same time, the air damper actuator lever must reach the stop.

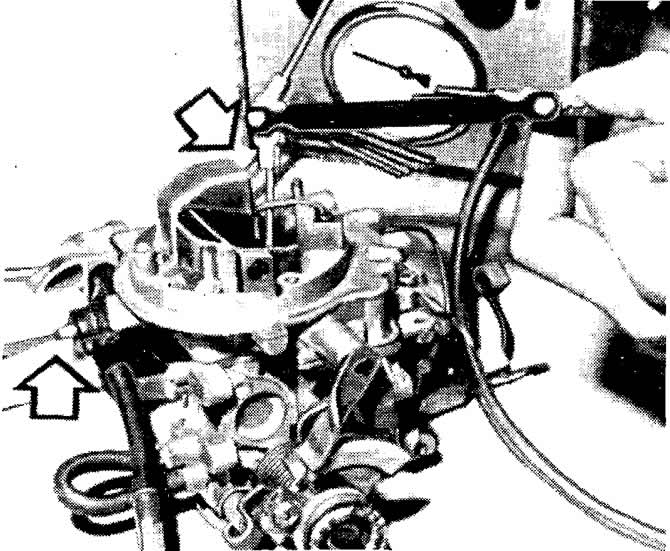

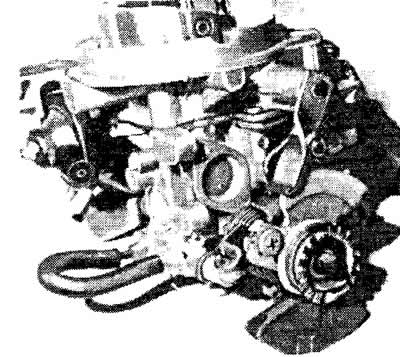

Connect the vacuum pump hose to the air damper actuator (see photo).

Adjustment of the starting gap of the air damper. The upper arrow shows the probe for measuring the starting gap, the lower arrow shows the adjusting screw of the air damper actuator rod.

Create a vacuum of 500 mbar in the pneumatic drive and measure the starting clearance of the air damper, which should be within 3.2±0.15 mm. If not, turn the adjusting screw of the air damper rod to set the required clearance.

After adjustment, make sure that the marks on the starting device cover and the carburetor body are aligned.

Throttle valve adjustment

This adjustment is made without removing the carburetor from the vehicle.

Fully push the choke control knob in.

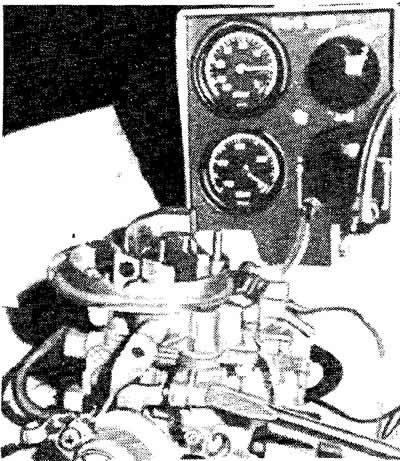

Connect the vacuum gauge hoses to the ignition distributor vacuum regulator and the carburetor.

Start the engine.

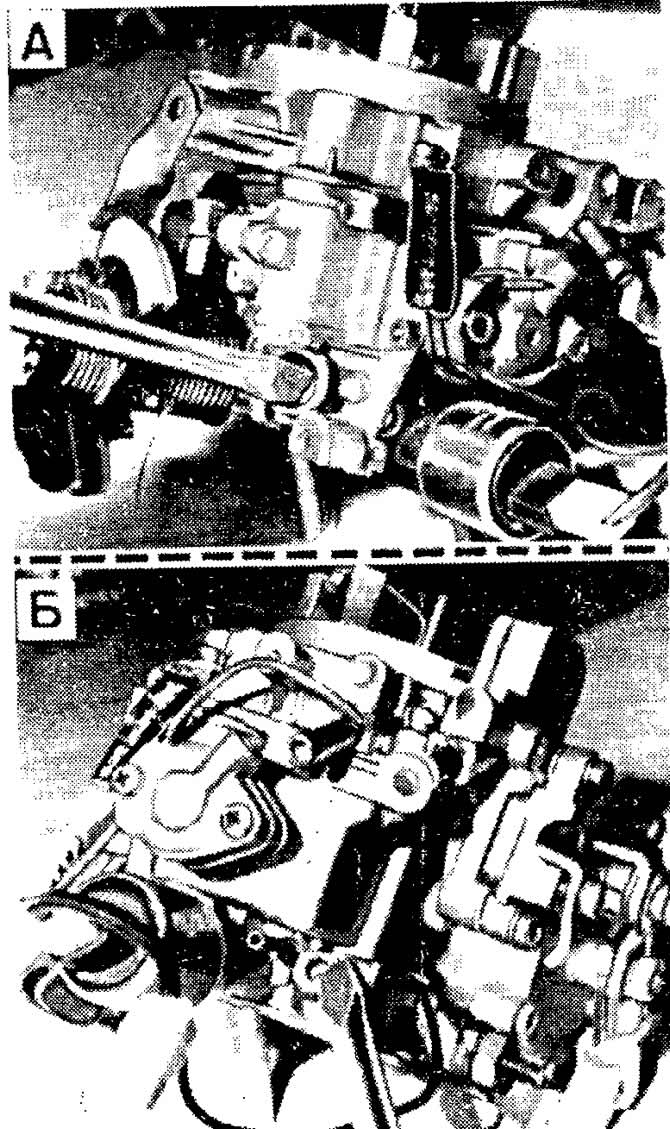

Turning the adjusting screw (see photo) slightly open the throttle, increase the throttle opening until the increase in vacuum stops.

Unscrew the adjusting screw until the minimum vacuum is obtained, then unscrew it another ¼ turn.

Install a new plug on the throttle adjusting screw.

Adjust engine idle.

Throttle valve adjustment

Throttle valve adjustment

Pull out the choke control fully.

Make sure the label (see photo) on the throttle control sector is opposite the end of the throttle restrictor screw.

Check the starting clearance of the throttle valve, which should be within 0.8±0.05 mm. If not, set the proper clearance with the throttle stop screw resting on the throttle control sector.

Install the carburetor in place and check the mode of accelerated idling of the engine at a coolant temperature of at least 60°C, which should be 4300-4700 rpm.

Throttle start gap adjustment

Checking and adjusting the performance of the accelerator pump

Place a funnel with a beaker under the carburetor.

Fully push the choke control knob in.

Slowly press the accelerator pedal ten times to failure.

Measure the amount of fuel in the beaker: for ten cycles, the accelerator pump must supply 15±2 cm of fuel.

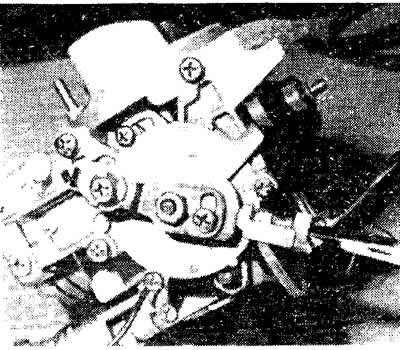

If necessary, adjust the performance of the accelerator pump by moving the cam of the pump drive lever on the bracket, after loosening the locking screw.

Adjusting the performance of the accelerator pump

Idle system adjusting screws:

A - mixture quantity screw;

B - quality screw (composition) mixtures

Engine idle adjustment

Idling adjustment must be carried out on a warm engine with adjusted clearances in the valve drive mechanism, with the ignition timing correctly set.

Connect the tachometer and gas analyzer in accordance with the operating instructions.

Adjusting screw for the amount of mixture (see photo) set the crankshaft speed within 900-1000 rpm.

Adjusting screw quality (composition) mixture to achieve carbon monoxide content (SO) in exhaust gases within 0.5-1.5%.

If necessary, restore the crankshaft speed within 900-1000 rpm, then adjust the CO content again. Carry out these operations until the idle speed and the CO content simultaneously correspond to the data.

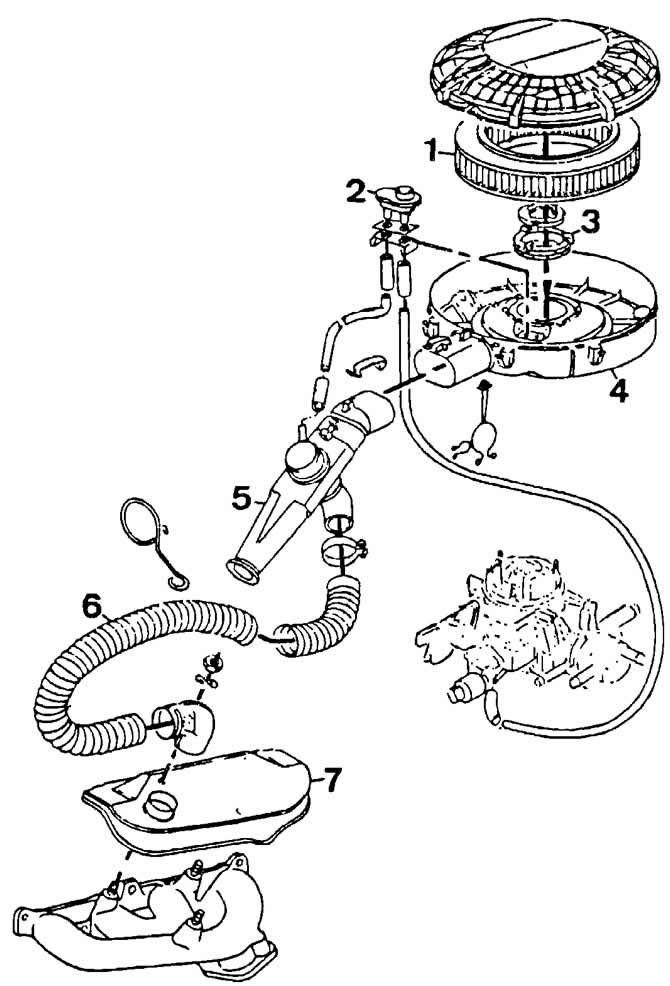

Air filter details:

1 - filter element;

2 - thermostat for heating the carburetor body;

3 - sealant;

4 - body;

5 - air intake pipe with thermostat;

6 - heated air intake hose;

7 - heated air intake shield

Visitor comments