Disassembly

Unscrew the adjusting bolts of the clearances in the valve drive as far as possible so that the valve drive levers can be removed.

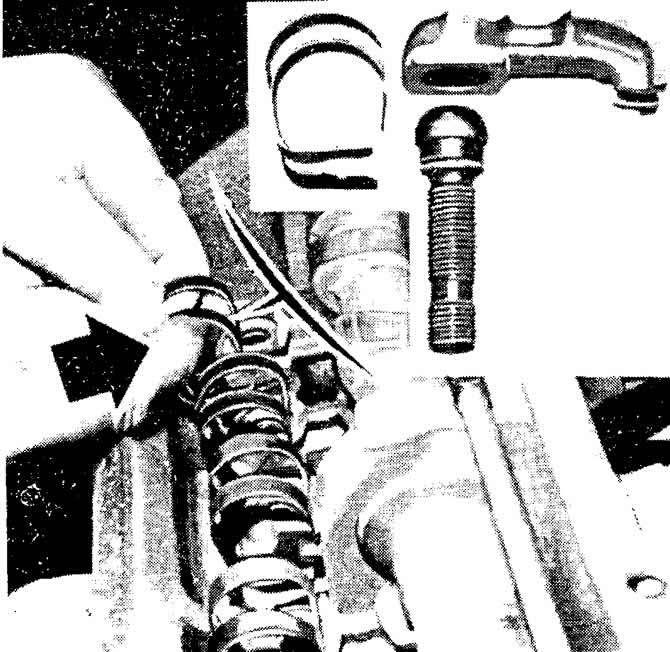

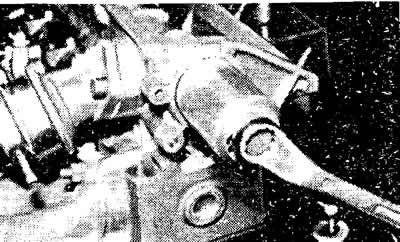

Remove the retaining springs of the levers and the levers themselves (see photo).

Removing the valve lever retaining spring

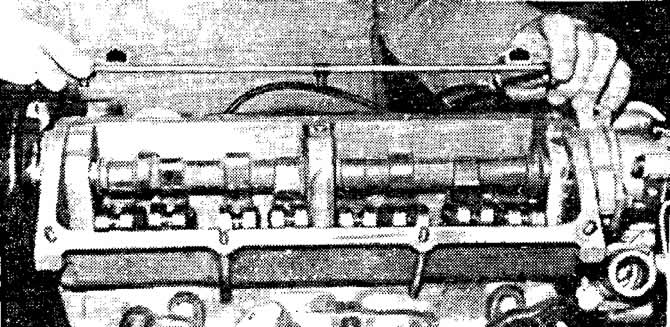

Remove oil line.

Remove the camshaft from the cylinder head bearings.

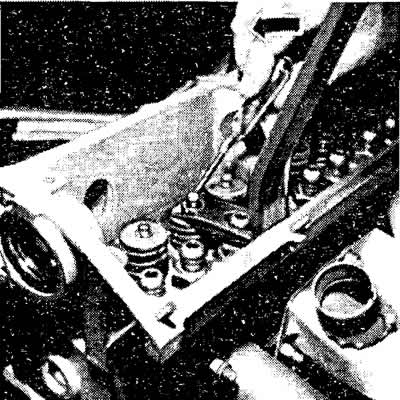

Compressing the valve springs with a special tool, release the valves from crackers and remove the valves.

Remove springs with plates.

Remove valve stem seals and spring washers using pliers 10 218.

If the removed parts do not need to be replaced, lay them out in order so that they can be installed in their original place during assembly.

Wash all removed parts.

Check valve guides for wear (See subsection for dimensions «Design and specifications»).

Measure the clearance between the valve stem and guide bushing using an indicator stand. To do this, insert a new valve into the guide sleeve so that its stem is at the level of the sleeve edge. Install the indicator foot on the valve head and measure the clearance.

Replace the guide bushings if the clearance exceeds the maximum allowable limit of 1.0 mm for intake valves and 1.3 mm for exhaust valves.

Using a ruler, check the flatness of the mating surface of the cylinder head and grind it if necessary.

Check the condition of the valve springs and valves.

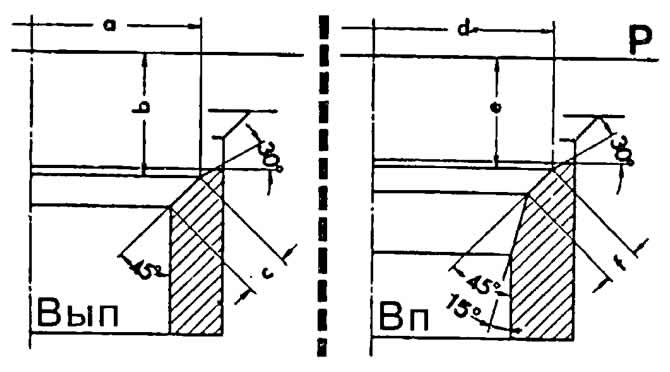

Check the condition of the valve seats and grind them if necessary. Grinding should be carried out only with the help of special equipment and in compliance with the dimensions specified in subsection «Design and specifications».

If necessary, grind the working chamfers of the inlet valves. The working chamfers of the exhaust valves are not subject to grinding. Lapping of exhaust valves is allowed, in other cases they must be replaced.

Thoroughly clean the cylinder head before assembly.

Assembly

Install the valve spring support washers, insert the valves into the guide bushings.

Using a VW 10 204 mandrel, press new valve stem seals onto the guide bushings, then put the protective bushings of the valve stem seals on the valve stems.

Install valve springs and spring plates. Install the cotters using the valve spring compressor.

Lubricate the bearing journals and camshaft cams with engine oil and install it together with the oil seal.

Install the levers on the adjusting bolts.

Install the retaining arms by sliding them into the grooves of the adjusting bolts so that the springs rest on the arms.

Note. If the thread of the adjusting bolt bushing is damaged, you can use a plug-in threaded bushing type «Heli-Coil» or SEDC

Using drift 10 203, press in camshaft oil seal.

Install the camshaft pulley and tighten its fastening bolt to a torque of 8 kgf.m.

Removing the oil line

Removing valve cotters

Dimensions for grinding valve seats:

Vp - inlet valve seat;

Vyp - exhaust valve seat;

R - mating surface of the cylinder head;

and - outer diameter of the working chamfer of the valve seat;

b and e - sinking of the working chamfer of the valve seat;

c and f - width of the working chamfer of the valve seat

Pressing in the camshaft seal

Visitor comments