Adjustment principle

The distance between the axis of the differential and the end of the drive gear determines the location of the contact patch in the meshing of the final drive gears. When installing the output shaft in the gearbox, this distance affects the degree of wear and noise of the final drive gears. Therefore, it must be adjusted with great care using a special tool.

The initial value for adjustment is the calculated value of the distance between the axis of the differential and the end face of the drive gear (size «Ro, see diagram), corrected by the amendment «G», determined during the manufacture of the drive gear. The adjustment consists in placing the adjusting ring S3 of the required thickness under the outer ring of the rear output shaft bearing to displace the drive gear in the gearbox housing.

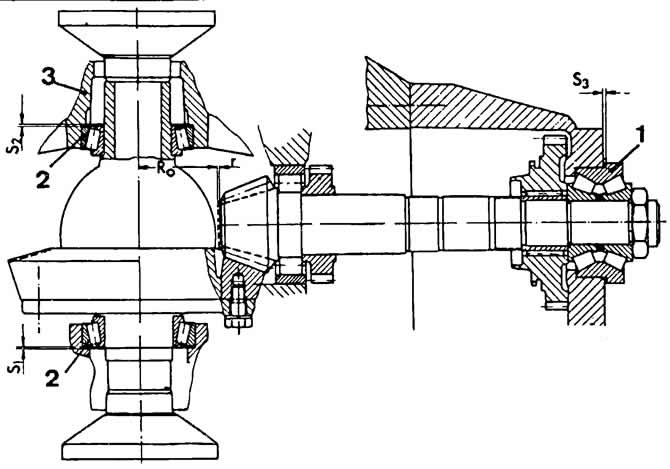

Adjustment and measurement of the distance between the end face of the drive gear and the axle of the differential and the side clearance in the meshing of the final drive gears:

1 - rear tapered roller bearing of the secondary shaft;

2 - differential bearing;

3 - clutch housing;

Ro is the calculated distance between the end face of the drive gear and the axle of the differential;

d - correction to the estimated distance between the end face of the drive gear and the axle of the differential (applied to driven gears supplied as spare parts);

S1, S2 - differential bearing preload adjusting rings;

S3 - adjusting ring for the distance between the end face of the drive gear and the axle of the differential.

Determination of the correction value «G»

Note. This measurement is made if there is no correction mark on the driven gear of the final drive «G» in hundredths of a millimeter from the nominal position of the drive gear, as well as if parts have been replaced / directly affecting the position of the drive gear of the final drive (output shaft rear double row tapered roller bearing, crankcase or transmission rear cover, 1st gear gear bearing).

Remove the gearbox rear cover.

Install a special adjusting washer VW 381/11 and fasten it strictly at a right angle relative to the output shaft by hand-tightening two M8x50 bolts.

Tighten bolts to 2 Nm using a torque wrench.

The drive gear, after tightening the bolts, takes the position that it occupied when the gearbox rear cover was installed. This operation must be carried out very carefully whenever the distance between the end of the pinion gear and the axle of the differential is adjusted.

Remove differential.

Install the measuring mandrel VW 385 in the clutch housing (calibrated for preload 2 mm) on «zero» using the VW 385-30 indicator.

Determine the estimated size «G», which is a deviation from the size «Ro».

When replacing parts by selecting the thickness of the adjusting ring, achieve the maximum possible accuracy of maintaining the resulting size «G».

Selection of the adjusting ring of the rear bearing of the secondary shaft

If the final drive is to be used again, press the rear bearing outer race together with the old adjusting ring into the gearbox housing. If parts have been replaced, install the bearing outer ring without the adjusting ring.

Install the output shaft and press on the second rear bearing inner race.

Tighten the rear end nut of the output shaft to 10.0 kgf·m.

Install the special output shaft preload shim VW 381/11 as described in the previous paragraph.

Install measuring mandrel VW 385 (calibrated and preload 2 mm) on «zero» using the indicator VW 385-30 and measure the value «G», and compare it with the calculated value «G», if the main gear was replaced, or with the value marked on the driven gear when the main gear was replaced. If the resulting value «G» less than the calculated one, then a thicker adjusting ring S3 should be installed, and vice versa. The difference between the received and calculated values «G» indicates by how much to reduce or increase the thickness of the adjusting ring S3.

Remove the gauge set and install the matched adjusting ring S3 under the output shaft rear bearing outer race.

Check for correct adjustment.

Selection of an adjusting ring for differential bearings

The differential bearings must be installed with a preload of 0.40 mm.

Remove the o-rings, press the outer rings of the differential bearings out of the clutch housing and remove the adjusting rings.

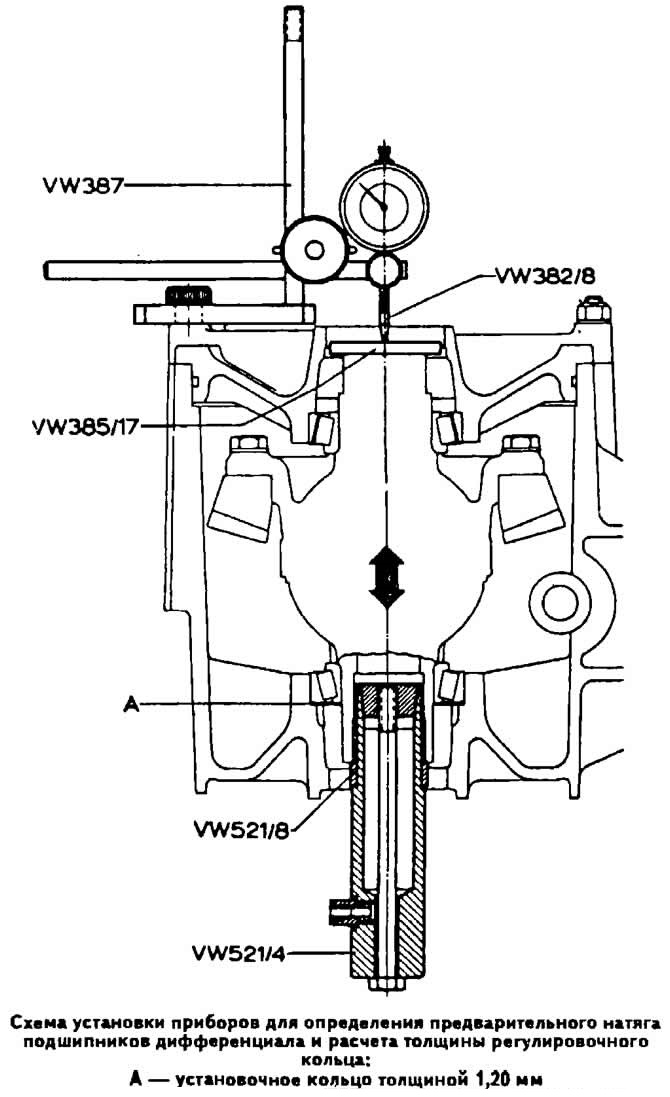

Press in the outer race of the tapered roller bearing from the side opposite the teeth of the driven gear of the final drive, with the setting ring «A» (see diagram) 1.20 mm thick.

Press in the differential bearing outer race on the side of the driven gear teeth without the shim.

Install the differential with press-on inner races without the speedometer drive gear and install the differential cover.

Install the differential so that its axis is in a vertical plane (see diagram).

Install the indicator support mandrel to the differential case.

Fix the indicator with a scale of 0-3 mm using a special tool. Mount the indicator leg on the support mandrel with a preload of 1 mm. In this position, fix the indicator and install it on «zero».

By moving the differential up and down, using, if necessary, bushings VW 521/4 and VW 521/8 (see diagram), determine the axial displacement by the indicator «IN» differential and calculate the thickness «S» differential bearing adjusting ring according to the formula:

S=A+B+C,

Where:

S is the thickness of the adjusting ring;

A - the thickness of the adjusting ring, equal to 1.20 mm;

B - the value of the axial movement of the differential;

C - the value of the preload of the differential bearings, equal to 0.40 mm.

Install adjusting rings of the required thickness under the outer ring of one of the differential bearings and check the backlash in the engagement of the final drive gears. If new bearings are installed, check the moment of resistance to rotation of the differential, which should be equal to 250 Ncm.

Adjustment of the side clearance in the gearing of the final drive gears

This adjustment is necessary when replacing the main gear of the gearbox housing, differential box and bearings, as well as when adjusting the distance between the end face of the drive gear and the differential axle.

Install output shaft and differential.

Rotate the differential a few times to align the bearings.

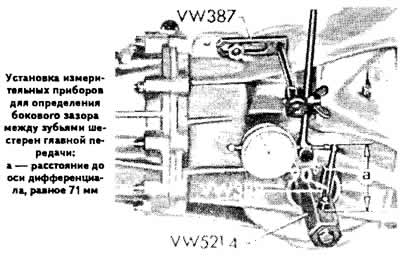

Install instruments for measuring the backlash between the teeth of the drive and driven gears during rotation of the differential and with the output shaft stationary; the measurement is taken along the diameter at a distance of 71 mm from the axis of the differential. The side clearance between the teeth of the driving and driven gears should be within 0.10-0.20 mm.

If the gap is not within the specified limits, move the adjusting rings from one side of the differential to the other until a normal gap is obtained.

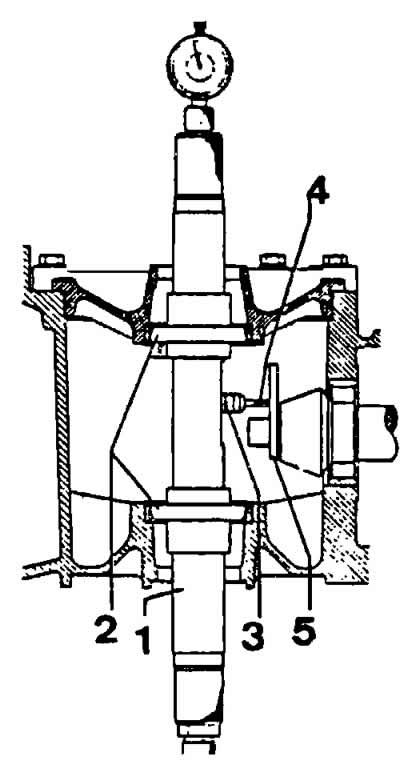

Scheme of installation of measuring instruments for calculating the distance between the end face of the drive gear and the differential axle:

1 - measuring mandrel VW 385/1;

2 - measuring mandrel VW 385/2;

3 - indicator rod VW 385/13;

4 - indicator extension VW 385/16;

5 - support mandrel of the indicator leg VW 385/33.

Visitor comments