The front wheels are equipped with a disc brake, which in models with engines from 107 hp. for better heat dissipation, it is cooled from the inside with air. Braking of the rear wheels, depending on the model, is carried out by self-adjusting shoe or disc brakes in models with engines from 107 hp

Above the master brake cylinder in the engine compartment is a compensation tank with brake fluid. Hydraulic clutch (not installed on all models) is supplied with brake fluid from the same tank. The pressure in both brake circuits is created by the brake master cylinder when the brake pedal is actuated.

The brake booster is driven by air vacuum. Thanks to the presence of a corresponding valve, the braking force generated by the brake pedal is increased if necessary with the help of a vacuum. Vacuum is taken from the intake manifold of the engine. Diesel engines have a special vacuum pump flanged on the side of the engine that creates vacuum for the brake booster.

Manual braking is carried out by acting through the cable on the brake pads of the rear wheels.

VW PASSAT vehicles are operated with disc brake calipers manufactured by various companies: Girling, Ate or VW-II. Therefore, when changing the brake linings, different work steps are required.

Cleaning the brakes raises brake dust, which can cause health hazards. Therefore, when cleaning the brake system, care must be taken to ensure that this dust is not inhaled.

Brake linings are covered by an operating permit - ABE (Allgemeinen Betriebserlaubnis), in addition, they are designed by the factory for the corresponding car model.

Therefore, it is recommended to use brake linings only from VW or approved by the Federal Motor Transport Authority - KVA (Kraftfahrtbundesamt). These brake linings have the appropriate KVA approval number.

Work on the brake system requires extreme cleanliness and precise working methods. If the necessary work experience is not available, work on the brakes must be carried out in a specialized workshop. Note: On roads that are very wet from rain, it is necessary to brake from time to time during the journey in order to free the brake discs from deposits. Due to centrifugal forces, water is discharged from the brake discs, but a thin silicone film, rubber wear products, grease and other contaminants remain, which reduce the effectiveness of the brake.

If the car is parked after a trip on a wet road, especially in winter, when the streets are covered with salt, it is advisable to brake by lightly pressing the pedal until it comes to a complete stop. In this case, the brake discs dry out and are less susceptible to corrosion.

Attention: If a change in brake pedal travel is detected after a turn, then the lateral runout of the brake discs on the outer diameter must be checked, if necessary, the brake disc must be replaced.

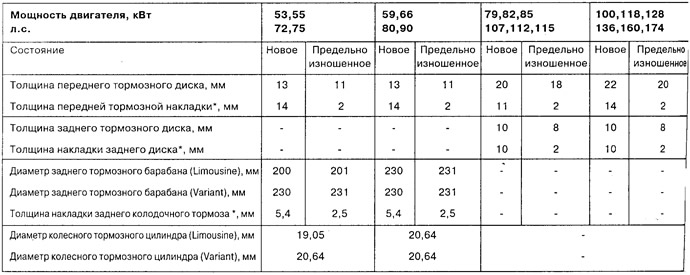

Specifications of the brake system

Car models up to 9/93

1) - excluding reverse side.

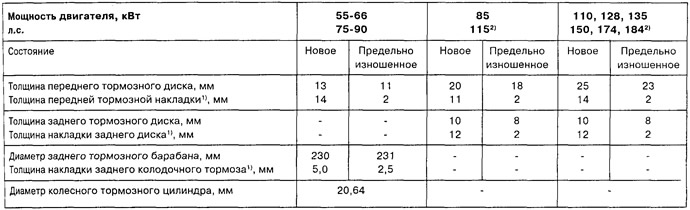

Car models since 10/93

1) excluding reverse side;

2) including version with synchronizer (all wheel drive).

Visitor comments