Removing

Loosen the wheel bolts, raise the car in front, remove the wheels.

Attention: If the brake linings are to be reinstalled, their location must be marked before removal. It is not allowed to change the pads in places, for example, change the outer one from the inner one or rearrange from the right wheel to the left and vice versa. Changing the location of the pads can lead to uneven braking action. It is recommended to use only original VW/AUDI brake pads. Front brake kit included, even if only one lining has reached the wear limit.

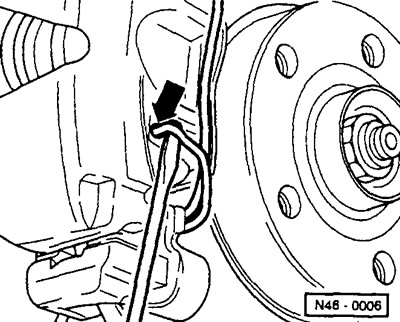

Using a screwdriver, press the spring holding the brake pads out of the caliper housing and remove it.

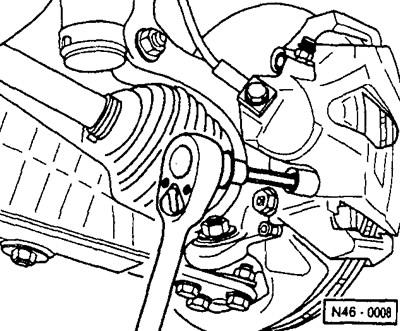

Remove the protective caps and unscrew both guide pins of the caliper housing.

Pull the caliper body upwards and lay it down so that the brake hose is not strained or damaged.

Take out the brake pads.

Installation

Caution: Do not depress the brake pedal when the brake pads are removed, otherwise the piston will be pushed out of the caliper body.

Attention: From 7/95, brake pads are installed that are oriented relative to the movement. Accordingly, an arrow is marked on the reverse side of the inner brake lining, which should point downwards when the lining is installed.

Clean the guide surfaces or pads in the pads with a suitable soft metal brush or wipe with a cloth soaked in alcohol. Do not use solutions containing mineral oils or sharp-edged tools.

Before installing the pads, examine the brake discs to the touch with your fingers for the absence of recesses. Notched discs can be turned (workshop work), depending on whether they have sufficient thickness. Always turn discs on both sides and pay attention to whether sufficient wear reserve remains after turning.

Measure the thickness of the brake discs, see below.

Check dust caps for cracks. Replace damaged caps immediately, as penetrating dirt will quickly break the tightness of the caliper. In this case, the caliper must be removed and disassembled (workshop work).

Bring the piston of the brake cylinder back into the cylinder with a return tool. You can also use a hardwood rod for this (hammer handle), however, pay particular attention to ensure that the piston is not distorted and that the piston surfaces and the dust cap are not damaged.

Attention: When installing the piston in the cylinder, the brake fluid is squeezed out of the brake cylinder into the compensation tank. Monitor the fluid level in the tank and, if necessary, suck out excess fluid with a siphon.

For suction, use a bottle that was used to remove air from the hydraulic system, or a plastic bottle that previously only came into contact with brake fluid. Do not use bottles intended for drinking liquids! Brake fluid is poisonous and must never be sucked out by mouth through a hose. Use a siphon. The brake fluid flowing out of the reservoir gets under the main brake cylinder, destroys the varnish coating and leads to corrosion.

Attention: If the brake linings are heavily worn, check that the piston can move freely. To do this, insert a wooden block into the caliper and ask an assistant to slowly depress the brake pedal. The piston of the brake cylinder should be easily squeezed out and re-entered. During the check, another caliper must be installed in its place. Make sure that the piston is not completely pressed out. If the piston stroke is heavy, the caliper must be repaired (workshop work).

Attach the inner brake lining with retaining spring to the piston of the wheel brake cylinder.

Attention: If there are overlays oriented relative to the movement, the arrow on the back of the overlay must point downwards.

Insert the outer brake lining into the brake shield and remove the protective film from the back of the lining.

Insert the piston housing and tighten it to the brake plate using guide pins to a torque of 25 Nm. Replace damaged guide pin caps (are included in the repair kit).

Insert both protective caps and the retaining spring into the caliper body.

Screw on the wheel. Lower vehicle and tighten wheel bolts crosswise to 110 Nm.

Caution: Depress the brake pedal strongly repeatedly until strong resistance is felt. In this way, the brake linings are centered and positioned appropriately for the operating conditions.

Check the level of brake fluid in the expansion tank and, if necessary, top up the tank to the mark «MAX».

Carefully run in the new brake pads, for which you repeatedly slow down the car by lightly pressing the brake pedal. Allow the brakes to cool down between braking.

Visitor comments