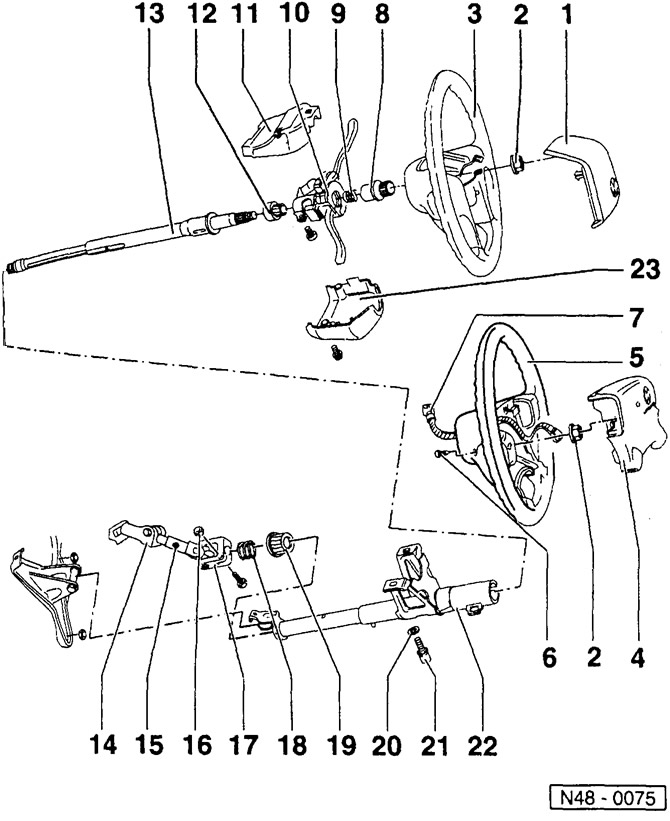

- 1 - cover

- 2 - nut, 50 Nm

On vehicles up to 9/93, together with an additional washer.

- 3 - steering wheel

- 4 - airbag assembly

- 5 - steering wheel for airbag

- 6 — a bolt with an internal hexagon

Replace after removal.

- 7 - plug connector

- 8 - adapter sleeve with slots

Until 1/89, instead of the sleeve, a lock washer was installed, which should always be replaced: remove with tongs, install with a piece of pipe.

- 9 - spring

- 10 - steering shaft bracket

- 11 - top lining

- 12 - support ring

- 13 - steering column

From 1/89 to present, the diameter has been changed from 20 to 22 mm.

- 14 - bolt, 30 Nm

- 15 - nut, 25 Nm

- 16 - nut, 30 Nm

- 17 - cardan joint with a cross

- 18 - spring

- 19 - lower bearing

Knock out with the pipe down, insert with the special tool VW-771 and a large washer.

- 20 - washer

- 21 - shear bolt

- 22 — a pipe of a steering column

- 23 - bottom lining

Steering consists mainly of steering wheel, steering column, steering gear rack and tie rods. The steering wheel is screwed to the steering column, which transmits the movement of the steering wheel to the steering gear. The steered wheels turn to the right or left according to the movement of the steering gear rack. Tie rods, which are attached to the gear rack pivots, transmit the steering force to the wheels through the hub bearing housings.

The rack and pinion steering is maintenance-free, but the seals must be checked for perfect condition.

Depending on the model or equipment, steering is made easier by hydraulic power steering. The hydraulic power steering ensures that the effort required to turn the steered wheels is as low as possible. The power steering consists of an oil pump, oil reservoir and pipelines. The oil pump is driven by a V-belt. The pump takes oil from the reservoir and delivers it under high pressure to a valve located in the steering gear housing. The valve is mechanically connected to the steering column and directs the oil, depending on the position of the steered wheels, into the corresponding chamber of the working cylinder. The oil presses on the rack piston and thereby increases the force exerted by the driver on the steering wheel. At the same time, through the drain groove of the spool valve, the piston squeezes the oil from the other chamber of the working cylinder into the return line and through it back to the oil reservoir.

As an additional equipment, a mechanism for adjusting the steering wheel in height is provided. Thanks to this, the driver has the opportunity to set the steering wheel in a comfortable position. Steering wheel height adjustment is mechanical. After releasing the lever of the mount, the steering column becomes movable relative to the pipe surrounding it. Two return springs pull the steering wheel to its highest position, making it easier to raise the steering wheel in various driver's seat positions. Now the steering wheel can be smoothly set to a comfortable position for the driver. The adjustment path is approximately 60 mm.

After adjustment, the mounting lever must be pushed up to the stop again so as not to unintentionally change the position of the steering wheel in height during the trip. The steering wheel height adjustment mechanism does not require maintenance, the uniform clamping action of the mount is guaranteed for the entire period of vehicle operation.

Caution: Always replace self-locking nuts. Welding and straightening work on steering parts is not allowed.

Visitor comments