General instructions

Replace defective bellows immediately. To replace the covers, the cardan shaft must be disassembled. If dirt has penetrated the grease, wash the joint and fill with new G6 grease. The defect of the hinge balls is recognized by the shock load change during the transition to the engine braking mode and by clicking noises. In this case, replace the joint as a set.

Attention: When the cardan shaft is dismantled, it is impossible to move the car, because in the absence of axial preload, the hub bearing is damaged.

Disassembly

Remove cardan shaft.

Cut the clamps on both hinges with wire cutters and remove. Move hinge covers back.

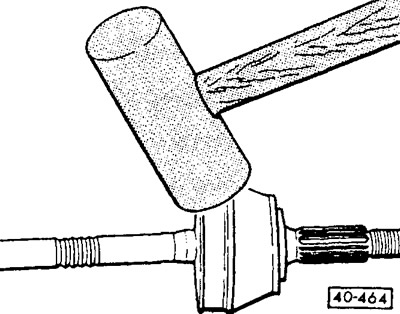

Outer joint: knock the joint off the propeller shaft with strong blows from a light alloy hammer.

Internal hinge: knock the protective cap off the hinge with a suitable rod.

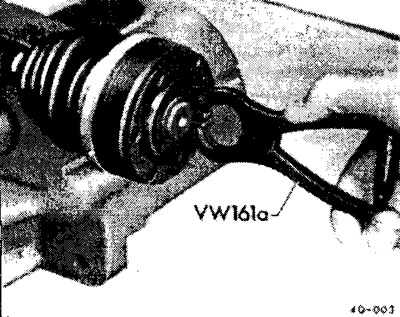

Internal joint: remove the circlip with suitable pliers, eg VW-161a or HAZET 2525K.

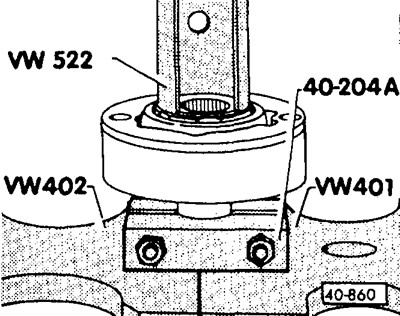

Remove the inner hinge with a suitable press. In doing so, support the hinge hub.

Remove the disc spring and bellows from the cardan shaft.

Inner joint: In vehicles with engines from 90 hp. and on all models from 10/93, remove the additional seal.

Assembly

Replace fragile or defective covers.

To put on a shaft a cover with a collar for the internal hinge.

Inner joint: Slide the disc spring onto the cardan shaft. In this case, the belleville spring should be correctly installed: its large diameter rests on the hinge.

Inner joint: fill the new joint with 110 g of G6 grease. In this case, distribute the grease evenly between the joint and the bellows. If only the bellows are to be replaced, the joint must only be greased.

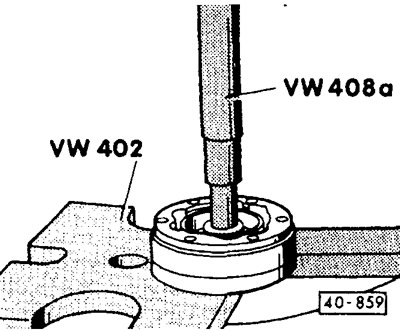

The inner hinge is pressed to the stop using a suitable press.

Note: Chamfer on inner diameter of pivot hub (ring gear) must face the propshaft bearing collar.

Fit a new circlip into the groove of the shaft with suitable pliers!, eg VW-161a or HAZET 2525.

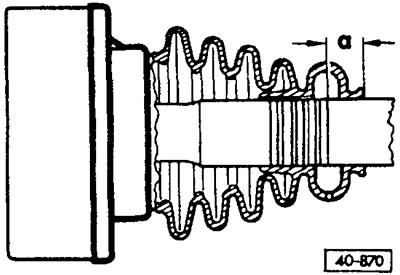

Vehicles with engines from 90 hp and all models from 10/93: mark installation dimension for bellows.

Before installing the bellows on the cardan shaft, mark the installation position with paint or adhesive tape. Do not use: scriber, and do not damage the protective varnish with any other sharp object.

Left cardan shaft: dimension a = 17mm

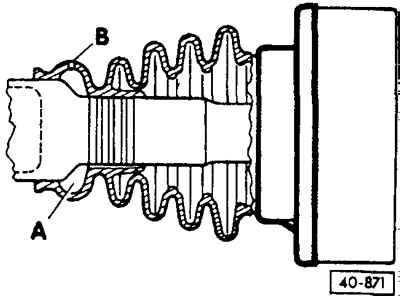

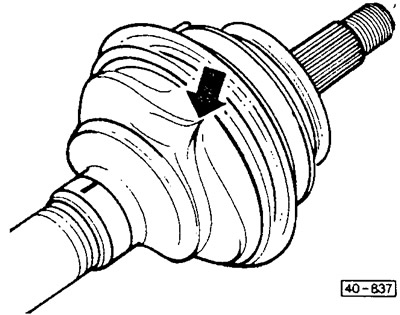

Right propshaft: the large diameter ventilation chamber -A- must be pushed onto the large diameter shaft tube. B - ventilation hole.

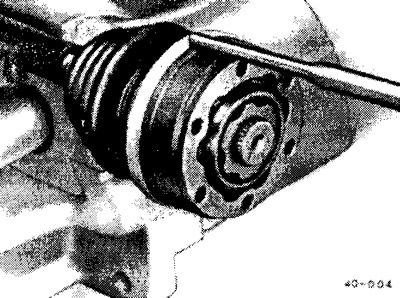

Internal joint: Lubricate the clean end of the cap of the joint boot with VAG-D3 repmetic. Put the cap on the hinge body.

Put on the shaft a corrugated cover for the external hinge together with a clamp and a clamp.

Outer hinge: Fill new hinge with 110 g of G6 grease. In doing so, distribute the grease evenly between the hinge and the bellows. If you are only replacing the bellows, only add grease to the hinge.

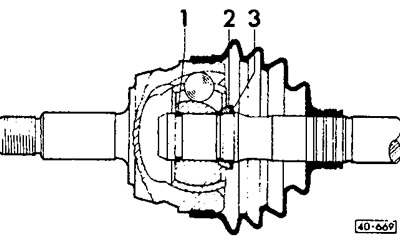

Fit disk spring -3- and spacer -2- onto propshaft. In this case, the Belleville spring should be correctly installed: its large diameter rests on the spacer washer. The spherical surface of the distance washer faces the hinge.

Insert a new circlip into the shaft groove. Drive the retaining ring onto the shaft with a rubber mallet until it locks into the groove.

Push the cardan joint of equal angular velocities onto the shaft with blows of a plastic or light metal hammer.

Position the bellows in the correct position and secure collar.

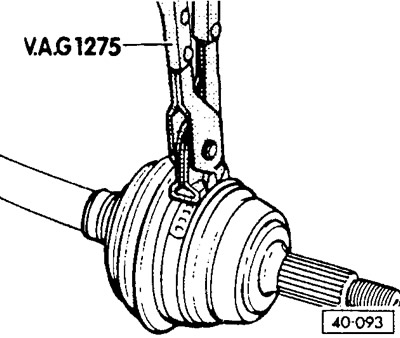

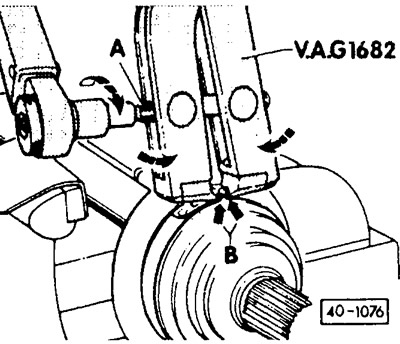

1.6 liter petrol and supercharged diesel engines: Vehicles with these engines have improved bellows on the outer driveshaft joints from 1/90. In connection with the more durable material of the covers, new alloy steel clamps are also installed. These clamps can no longer be tightened with the old VAG 1275 pliers. The pliers shown in the figure must be used. The cutters of the pliers should be in contact with the corners (arrows B) collar. In this position, tighten the bolt -A- with a torque wrench to 25 Nm and thus tighten the clamp. The tightening of the clamp on the small diameter of the corrugated cover is performed in a similar way.

Attention: The cover often shrinks when installed on the hinge body. As a result, under the cover there is a rarefaction of air, which during operation draws the cover inside. Therefore, after mounting the cover, you need to slightly lift its edge with a screwdriver on the side of the small diameter and thereby ensure pressure equalization.

Inner joint: In vehicles with engines from 90 hp. and on all models from 10/93, glue a new seal into the hinge, having previously removed the protective film from it.

Visitor comments