Attention: When the cardan shaft is dismantled, the car must not be moved, because in the absence of axial preload, the hub bearing is damaged. If necessary, install an external joint instead of the cardan shaft.

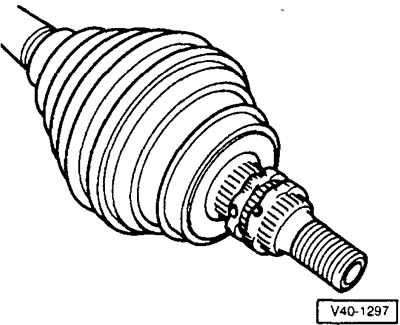

When replacing the cardan shaft, move the vibration damper to the new shaft. Note: Vehicles with 4-cylinder engine and automatic transmission from 2/94 are fitted with CV joint shafts «tripod». To remove the left cardan shaft, it is necessary to suspend the engine and release its supports. The inner cardan joint can only be replaced together with the cardan shaft.

Removing

Loosen the nut securing the wheel hub to the propeller shaft.

Attention: The car must be on wheels. Danger of accident!

Basic undercarriage: remove the washer.

Loosen the wheel bolts and raise the vehicle.

Remove the wheel.

Unscrew the bolts securing the inner hinge with internal slots on the head. To do this, use a key with an interchangeable socket head with external slots, for example, HAZET 990 Lg-8.

Mark the mutual position of the ball joint and the transverse lever, for which, circle the heads of the mounting bolts with a scriber.

Basic undercarriage: fastening bolts (arrows) turn out.

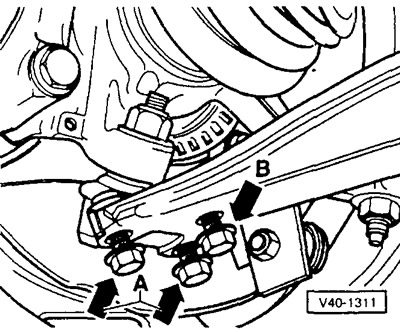

Positive running gear: first remove bolts -A-, then bolt -B-.

Separate the ball joint from the transverse link.

If the propeller shaft cannot be pulled out by hand, press it out of the wheel hub with a suitable puller. The VW workshop uses the VW-3283 puller for this.

Tilt the shock absorber strut outward and pull the driveshaft out of the wheel bearing housing.

If the cardan shaft is to be replaced, remove the vibration damper. To do this, knock out the clamping sleeve and separate the 2 halves of the damper.

Attention: From 8/89 to 9/93 one-piece absorbers were installed. To remove it, you must first press out the internal universal joint of equal angular velocities, and then the absorber.

Installation

If it was removed, replace the vibration damper and drive in a new clamping sleeve. Attention: At the same time, close the shaft so as not to damage the protective packing coating during driving. Before installation, check the effectiveness of the action on the inner diameter of the adhesive tape absorber. If necessary, replace the adhesive tape or apply another adhesive. The adhesive tape prevents the damper from moving axially along the cardan shaft.

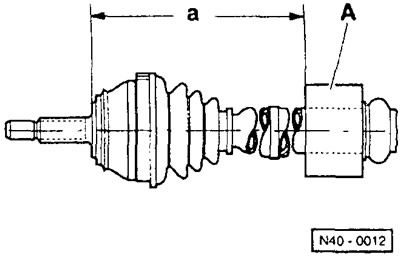

Installation dimensions for vibration damper (all models):

Right cardan shaft: a = 521±1 mm; left propeller shaft (if the damper is installed): a = 264±1 mm.

Attention: For vehicles built before 10/88, see the instructions at the end of the section.

Before installation, clean the splines of the cardan shaft to remove oil and grease with gasoline, and also remove all deposits from the protective coating.

Positive running gear:

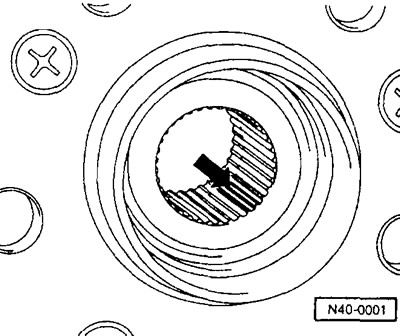

Up to approx. 12/94: Apply VW D185400A2 to the splines as shown in the figure. The cross section of the protective agent layer is approximately 3 mm.

Attention: From about 12/94, a modified wheel hub is installed, the tops of the splines of which are slightly compressed. The new hub can also be fitted to older vehicles. If such a hub is installed, no protective agent is required.

Insert the cardan shaft into the wheel hub and secure with the old nut. Tighten the nut until the axle shaft of the outer joint enters the hub as far as it will go. Do not tighten the nut.

Screw the ball joint to the transverse link to a torque of 35 Nm, while making sure that the bolts are in line with the previously marked marks.

Bolt propshaft to gearbox output flange.

Screw in the head bolts securing the inner joint and tighten them crosswise to 45 Nm. Don't forget to put lock washers under the 6omJ.

Positive undercarriage

From about 12/94 or vehicles with a new wheel hub:

Loosen the nut securing the wheel hub to the propeller shaft.

Lubricate the contact surfaces of the new 12-point nut with oil and tighten it as far as possible.

Lower the car. When doing this, make sure that the wheels do not touch the floor yet, otherwise the hub bearing may be damaged.

Apply brakes (need help).

Tighten the 12-point nut to 200 Nm, then loosen one turn.

Tighten the 12-point nut to 50 Nm.

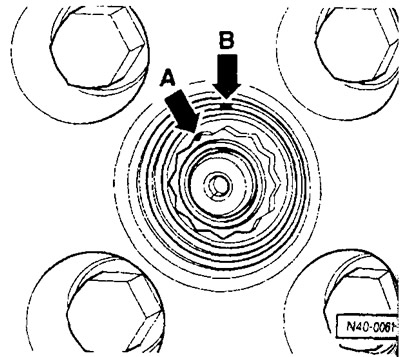

Mark the top of the 12-sided nut with a scriber (arrow A. fig. №40-006).

Second label (arrow B) apply on the edge of the wheel hub opposite the next top of the hex nut.

Note: The angle between two adjacent vertices of a 12-hedron is 30°.

Tighten the 12-point nut to the specified angle until the marked marks match.

Install the front wheel, setting it to its previous position relative to the mark on the hub, lower the car and tighten the wheel bolts in a crosswise manner to a torque of 110 Nm.

Basic running gear: Loosen the nut securing the hub to the cardan shaft and install a new self-locking nut, tightening it to 265 Nm. Don't forget to install the washer.

Positive running gear up to approx. 12/94: Loosen the hub-to-propshaft nut and install a new self-locking 12-point nut. Tighten the nut to 90 Nm and tighten 1/8 turn (45°). Attention: Apply the handbrake. Have an assistant apply the foot brake. When tightening, the vehicle must be on its wheels. Danger of accident!

Install wheel cover.

Check wheel alignment if necessary (workshop work).

Visitor comments