Attention: A defect in the preheating system causes difficulties when starting a cold engine, especially at ambient temperatures below +10°C.

Checking the supply voltage

Test prerequisites: Engine cold (has ambient temperature), the battery is charged (voltage not less than 12 V).

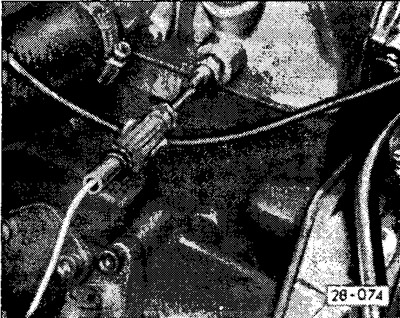

Connect voltage tester to cylinder 4 glow plug and ground (-).

Turn the ignition key to position «Vorgluhen» - preheating (ignition on).

If the indicator does not show voltage, then it is necessary to check the plate fuse (80 A) glow plugs for damage (microcracks), installation strength and contact quality. If necessary, clean the contacts, tighten the fastening or replace the fuse. The blade fuse is located in the fuse box.

Load current test

In order to check the load current of an individual glow plug, a workshop uses a DC clamp ammeter, such as the VAG-1315A. The clamp is connected to an insulated cable and the current value is measured through induction.

If there is a clamp, connect it to the glow plug supply wire.

Turn on the ignition, warm up the glow plugs, start the engine and let it idle.

During the post-heating of the glow plugs (up to 120 s) determine the value of the load current when the engine is running:

Each glow plug draws approximately 8 A. If the measured load current is approximately 32 A, then the glow plugs are OK.

- At a current of 32 A, all candles are in order

- At a current of 24 A, 1 candle is faulty

- At a current of 16 A, 2 candles are faulty

- At a current of 8 A, 3 candles are faulty

- At a current of 0 A, all candles are faulty

Attention: When current flows through a glow plug, its performance cannot be ascertained by sovereignty. Carrying current candles may also be faulty,

Finding a Faulty Glow Plug

Remove all injectors see below.

Pull out the heat shield seals.

Turn on the ignition and «Vorgluhen».

Observe through the holes of the injector nozzles which glow plugs are glowing or, conversely, have a defect.

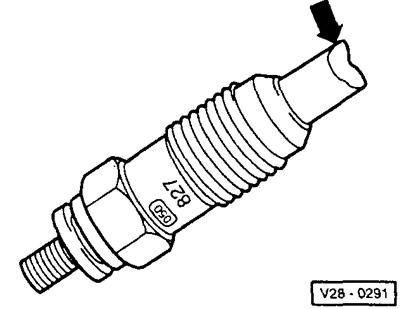

Glow plugs with burnt pin

Burnt glow plug pins are often the result of malfunctioning injector nozzles. This type of damage cannot be attributed to flaws inside or outside the glow plug.

If such a candle is found in the event of a claim (arrow), then it is insufficient to replace such a candle only. It is necessary to check the injector nozzles for injection pressure and tightness (workshop work).

Diesel engine with gas turbine supercharging

Prerequisites for verification:

- The battery is charged, the battery voltage is at least 11.5 V.

- The diesel injection system control unit is OK.

- Ignition off.

Examination

Check glow plug fuse plate for damage (fine cracks), installation strength and contact quality. If necessary, clean the contacts, tighten the fastening or replace the fuse. The blade fuse is located in the fuse box.

Disconnect the coolant temperature sensor connector. This simulates the cold state of the engine. The temperature sensor is located on top of the coolant connection on the left side of the cylinder head.

Disconnect plugs from glow plugs.

Connect a voltmeter between the glow plug plug and vehicle ground.

Turn on the ignition. The voltmeter should show battery voltage for about 20 seconds. Check all connections in the same way.

If there is no voltage, check the electrical wires according to the wiring diagram.

Checking glow plugs

Ignition off. Disconnect plugs from glow plugs.

Connect a test lamp on semiconductor diodes to the positive pole of the battery (+) and connected in series to each glow plug.

If the control lamp lights up, the glow plug is OK.

If the control lamp does not light up, replace the glow plug. Screw tightening torque: 15 Nm.

Connect the plugs of the glow plugs.

Visitor comments