K-Jetronic, engine with KR designation

Attention: On a KE-Motronic engine with the designation 9A, the idle speed is only checked, not adjusted. In addition, before checking, it is necessary to interrogate the memory device of the control unit, for which you should contact the VAG workshop. The prescribed values are: for the idling speed of the crankshaft - 800±100 1 / min, for the CO content measured through the selection tube in the engine compartment - 0.2-1.2% by volume. Conditions for checking and adjusting (4 subsequent paragraphs) as with the K-Jetronic system.

Warm up the engine to an engine oil temperature of at least +80°C.

Turn off all electrical consumers, including the air conditioning system.

If the fuel lines have been disconnected or replaced, then before checking the engine shaft must be brought to a speed of 3000 1 / min several times, and then for at least two minutes the engine must be left to idle.

Check ignition timing, see chapter «Ignition system».

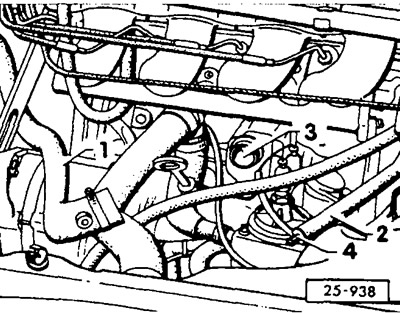

Detach hoses -1-and-2- for crankcase breather from breather housing and lay in such a way that only fresh air can be sucked in. Loosen hose clamps first. The connecting piece -4- with the calibrated hole must remain in the hose -2-.

The control valve of the engine idle speed stabilization system should vibrate and buzz. If necessary, check the stabilization system, see below.

Attention: Only connect devices with the ignition switched off.

Connect a tachometer and a CO meter in accordance with the service manual, paying attention to the precautions when working with electronic ignition systems, see chapter «Ignition system».

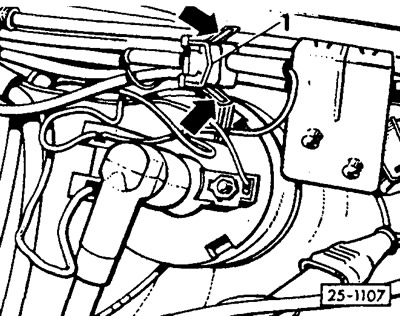

Unplug electrical connector -1- next to ignition coil.

Caution: The cooling fan must not rotate during inspection and adjustment work.

Check the engine speed when idling. Prescribed value: 1000±50 1/min.

Check CO content. Prescribed value: 1.0±0.5% by volume.

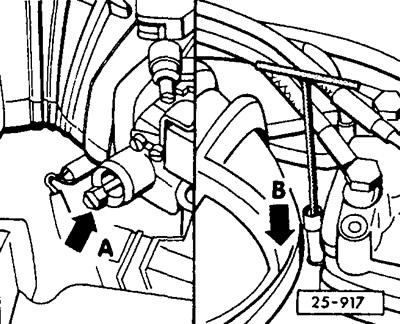

If necessary, alternately turn the idling speed adjusting screws -A- and the CO content -B- to adjust the above parameters.

Pull out the protective cap of the CO adjustment screw. To do this, drill the cap with a drill with a diameter of 2.5 mm, and screw in a screw with a diameter of 3 mm into the drilled hole. Using pliers, pull out the cap by the screw.

Adjust the CO content with a 3 mm Allen key (arrow), for example, HAZET 4516.

Attention: When adjusting the CO content, do not press the adjusting screw down with a wrench or, accordingly, do not raise it. Do not apply gas with the adjusting key inserted (bending hazard).

After each adjustment, immediately remove the adjusting key and give gas briefly.

Attention: If the engine speed is not regulated to the prescribed value, check the idle speed stabilization system.

After adjusting, insert a new safety cap using the pin.

Reconnect the high voltage wire next to the ignition coil.

Connect the crankcase ventilation hoses to the cylinder head and secure with clamps.

Attention: If the CO content has now increased, then the reason is not an incorrect adjustment, but an enrichment of the combustible mixture due to the intake of gasoline vapors from the crankcase, where gasoline enters mainly when traveling short distances.

During long continuous trips, the proportion of gasoline in the engine oil decreases, and the CO content in the exhaust gases returns to normal. It can also happen quickly after a 30-minute drive or another oil change.

Switch off measuring devices with the ignition off.

Visitor comments