Check the vacuum hose to the forced idle switch valve for porosity and cracks, replace the hose if necessary.

Start the engine and increase the engine speed to about 2500 rpm. At this speed, operate the idle switch at the throttle valve, see above.

The engine speed should now periodically drop and rise again (engine «sawing»).

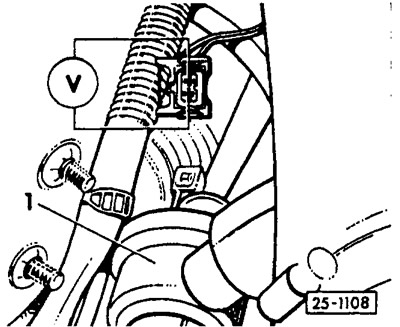

If no change in the engine speed is detected, disconnect the plug from the valve and measure the voltage at the plug contacts with a voltmeter. The prescribed voltage value at idle speed is 0 V (no voltage).

Increase the engine speed to 4000 rpm, then close the throttle abruptly and measure the voltage. As the engine speed drops to approximately 1400 rpm, the voltmeter should indicate approximately battery voltage (12 V).

If the voltmeter shows battery voltage, then the control is in order. Replace the forced idle switch.

If the voltmeter does not show battery voltage, check the parts in the following sequence: throttle angle sensor, temperature sensor, electrical wires and connections, control unit (workshop work). Replace defective parts.

Visitor comments