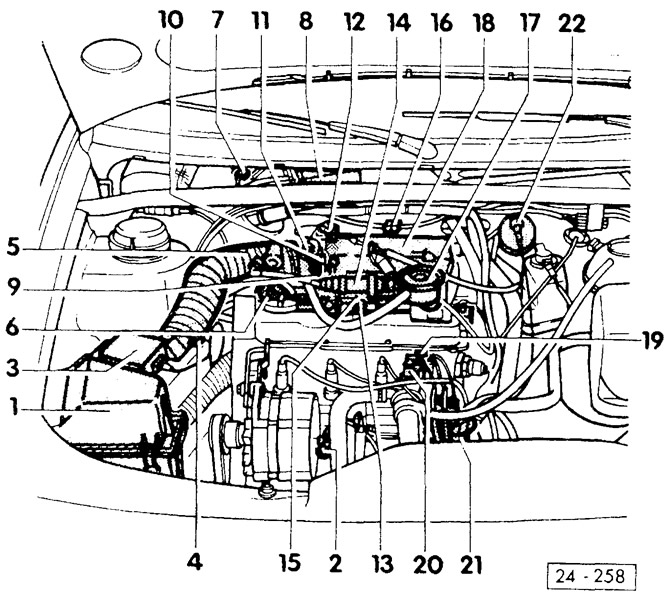

- 1 - air filter

- 2 - knock sensor

- 3 - air flow meter

- 4 - CO content adjustment screw

- 5 - inlet hose

- 6 - pressure regulator

- 7 - TSZ-H system switch

- 8 - control unit of the Digifant system

- 9 - screw for adjusting the crankshaft speed when idling

- 10 - throttle valve

- 11 - throttle switch I

- 12 - throttle switch II

- 13 - valve nozzle (4 pieces)

- 14 - valve of the crankshaft speed stabilization system when the engine is idling

- 15 - fuel distributor

- 16 - plug connector

For oxygen sensor and sensor heating system, only with variable catalytic converter

- 17 - pressure control valve

For crankcase ventilation system

- 18 - intake manifold

- 19 - temperature sensor

For coolant temperature gauge, black insulation.

- 20 - temperature sensor

For Digifant system, blue insulation

- 21 - ignition distributor

- 22 - ignition coil

The Digifant system is an electronically controlled petrol injection system in which fuel is injected intermittently, i.e. cyclically, into the intake manifold under each intake valve. Thus, the Digifant system, unlike the Mono-Motronic system, has a valve injector for each cylinder. The ECM controls the injection system, including idle control, knock-free combustion, activated carbon system, crankshaft speed range, self-diagnosis and ignition system.

Fuel is sucked from the fuel tank by an electric pump and fed through the fuel filter to the dispenser, and from it to the valve injectors. The distributor regulator ensures that the pressure in the fuel system is kept constant at approximately 2.5 bar. The vibration damper in the pressure regulator reduces pressure fluctuations in the fuel return line.

Digifant

Through the air filter, the engine sucks in air, the amount of which is determined by the volume flow meter. In the body of the volumetric flow meter there is a movable damper, which is deflected by the air flow to a certain position and is held in this position. The damper angle is a measure of the amount of air consumed by the engine. With the help of a potentiometer, the corresponding signals from the damper are transmitted to the control unit.

The crankshaft speed stabilization valve, when the engine is idling, regulates the speed, especially during the warm-up period of the engine and when consumers of electricity are connected to it.

The potentiometer is located directly on the throttle shaft. It transmits signals to the control unit about the position of the throttle, primarily at idle and full load. Thanks to this, in particular, the forced idle switch is controlled.

Simos (engines AFT, ADY, AGG)

The amount of fuel entering the engine is determined using a mass flow meter and an intake air temperature sensor, see section below «Motronic injection system». The control unit, in accordance with the signal from the mass air flow meter, regulates the duration of injection, and thus the amount of injected fuehp a longer opening of the valve injector, more fuel is injected. Additional sensors ensure that the amount of injected fuel is measured correctly in any driving situation.

The throttle control unit is located between the intake manifold and the intake air hose. It consists of throttle actuator motor, actuator motor potentiometer, throttle valve potentiometer, idle switch. The throttle valve actuator is a small electric motor with which the control unit sets the throttle valve to the position corresponding to the operating conditions. The actuator motor potentiometer transmits information about the instantaneous position of the motor to the control unit.

Visitor comments