Removing

Remove gearbox, see chapter «Transmission».

Loosen the clutch pressure plate mounting bolts sequentially, depending on the circumstances, by 1 or 1.5 turns until the clamping effect of the pressure plate is weakened.

Attention: If the bolts are released immediately completely, the diaphragm spring may be damaged.

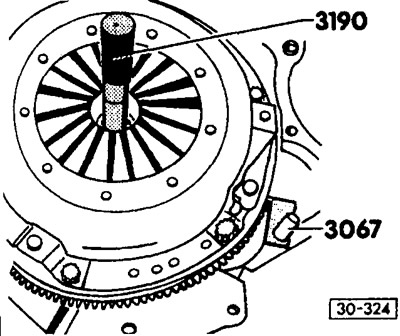

To prevent the flywheel from turning when the bolts are loosened, lock it either with VW 3067 or with a screwdriver and a pin.

After that, unscrew the bolts completely.

Remove the clutch pressure and driven discs.

Attention: Do not drop the discs when removing, otherwise, after assembly, difficulties may arise associated with pulling the clutch and separating the discs.

Remove the clutch release bearing from the guide bush.

Attention: only wipe the bearing, but do not rinse.

Wipe the flywheel with a gasoline-soaked rag.

Examination

Check the clutch pressure plate for roughness and burn cracks.

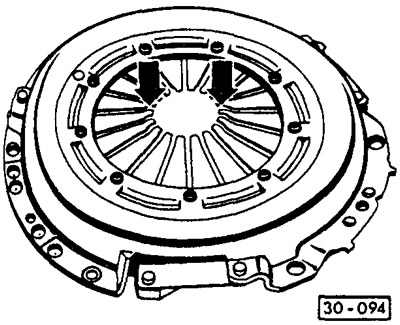

Examine the diaphragm spring for damage (arrows). Traces of running-in are allowed at the ends of the diaphragm spring to a depth of up to 0.3 mm.

Check the spring connections between the pressure plate and the cover for cracks, the strength of the rivet connections and the tightness of the installation. Replace clutch with damaged or loose rivets.

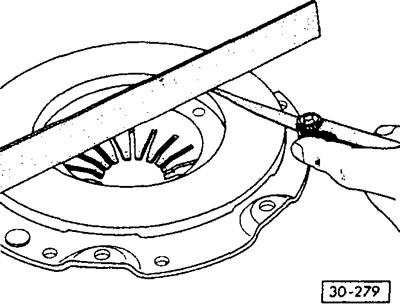

Check the contact surface of the pressure plate for cracks, burns and wear. Pressure plates with an inward deflection of up to 0.2 mm can be installed again. Checking is carried out with a metal ruler and a probe.

Check the flywheel for cracks from burns and bumps.

Replace the clutch disc with traces of oil and grease, as well as with mechanical damage.

Check the driven disk for a sufficient thickness of the linings and the absence of cracks on them.

In the workshop, the driven discs can be checked for runout. The maximum allowable lateral runout can be 0.8mm (2.5 mm when measured by outer diameter).

Attention: This check is only necessary if the old driven disc has to be reinstalled and the clutch was previously disengaged incorrectly. If necessary, the driven disk can be carefully straightened.

Check the clutch release bearing by hand. To do this, the bearing is easy to compress and rotate. The bearing must rotate easily, otherwise it must be replaced.

When installed, a defective clutch release bearing is noticed by the noise it makes when the clutch pedal is depressed. In this case, replace the bearing.

Installation

Attention: If new parts are installed, be sure to check the clutch pressure and driven plates with the designation and engine number against the spare parts catalog to exclude the installation of non-standard parts.

Before installing a new pressure plate, remove anti-corrosion grease only from the working surfaces of the clutch release bearing.

Check the alignment pins on the flywheel for firm seating.

Install the clutch disc and pressure plate to the flywheel. Place the pressure plate on the appropriate guide pins. The driven disk must be centered with a suitable pin (e.g. HAZET), or using an old gearbox input shaft.

Remove rust from the splined joint of the driven disk and lubricate with the thinnest layer of MoSg anti-friction grease. VAG workshops use G 000100 grease. After that, move the clutch disc back and forth along the gearbox drive shaft until the hub easily walks along the shaft. Excess grease must be removed.

When installing the driven plate, make sure that the spring cages face the pressure plate.

Screw in the pressure plate mounting bolts and sequentially tighten 1-1.5 turns in a crosswise manner until the disc is firmly tightened. Tightening torque: 20 Nm. Do not warp the pressure plate, otherwise the centering holes of the pressure plate and the centering pins of the flywheel will be damaged.

Then remove the center pin (old gearbox drive shaft).

Install gearbox, see chapter «Transmission».

Visitor comments