The steering mechanism is installed in the reverse order of removal, taking into account the following:

- attach the steering shaft to the steering mechanism, lifting the power unit with hoists;

- before installing the protective cover of the steering shaft, apply some kind of anti-friction compound to its surface;

- tighten the bolts of the terminal connection of the universal joint of the steering shaft;

- after installing the steering mechanism, check and, if necessary, adjust the angles of the front wheels and the position of the steering wheel.

Adjustment of a backlash between an emphasis and a lath of the steering mechanism

Set the steering mechanism to the middle position corresponding to the position of the rectilinear movement of the front wheels (pic. 6-5). Tighten the rack stop adjusting bolt located on the steering gear case by approximately 20°.

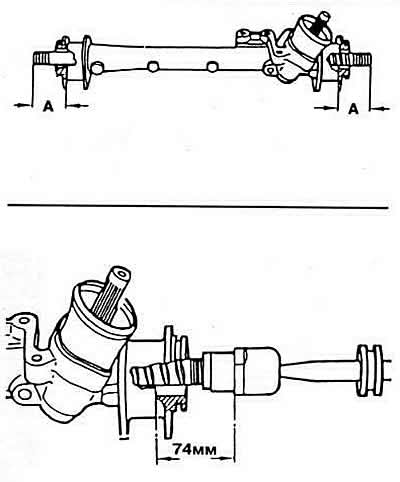

Pic. 6-5. Dimensions for connecting steering rods to the steering rack:

A - dimensions when installing the rail in the middle position; when screwing the tie rod end into the rack hole, observe the dimension 74 mm.

Check steering operation by test drive. Wherein:

- if, after turning the car, the steering does not return to the middle position, slightly loosen the adjusting screw of the rack stop;

- if there is a gap between the rack and stop, lightly tighten the rack stop adjusting bolt.

Adjustment of connection of steering drafts with the steering mechanism

When replacing the steering gear or tie rods, adjust the tie rod to steering gear connection as follows.

Set the rail to the middle position so that the distance «A» between the shoulder of the steering gear housing and the end of the rack (pic. 6-5) it was the same on both sides.

Fully unscrew the locknuts securing the steering rods to the rack.

Screw the tie rods into the rack holes so that the distance between the steering box shoulder and the ball joint shoulder is 74 mm. Tighten the tie rod locknuts.

Visitor comments