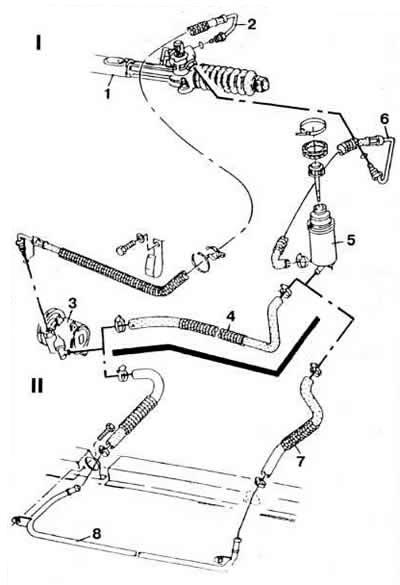

Pic. 6-6. Details of power steering system:

I - cars with gasoline engines

II - cars with diesel engines

1 - steering rack

2 - high pressure hose

3 - hydraulic booster pump

4.7 - suction hoses

5 - hydraulic booster reservoir

6 - drain hose

8 - working fluid cooler

Removal and installation of the steering mechanism

To remove, disconnect the suction hose from the power steering pump and drain the working fluid from the hydraulic system. Using a universal ball joint puller, disconnect the tie rods from the steering box. Unscrew the bolt of the terminal connection of the universal joint of the lower steering shaft with the drive gear of the steering mechanism. Sling the power unit with hoists. Remove the protective cover of the steering shaft from the seat on the housing of the steering mechanism. Loosen the engine mount subframe bolts.

Slowly lower the power unit with the hoists. In this case, the steering shaft should be easily disconnected from the steering mechanism. Disconnect the two hydraulic hoses from the steering gear housing and plug the openings of the housing and hoses.

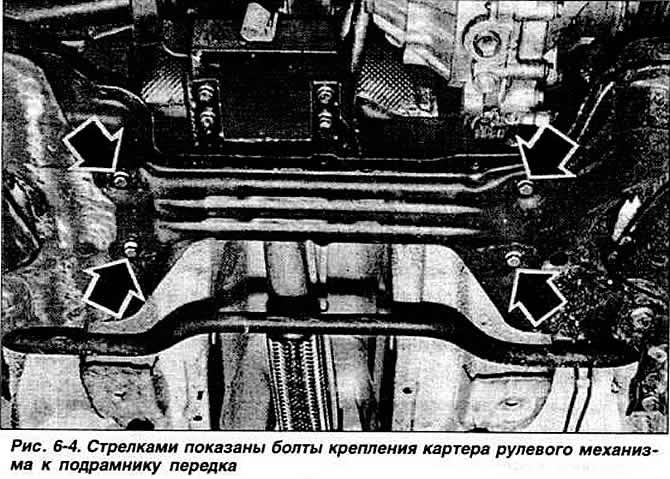

Unscrew the four bolts securing the steering gear housing to the front subframe (pic. 6-4).

Remove the steering gear by moving it towards the rear of the vehicle.

Installation of the steering mechanism is carried out in the reverse order of removal, taking into account the following:

- attach the steering shaft to the steering mechanism, lifting the power unit with hoists;

- before installing the protective cover of the steering shaft, apply some kind of anti-friction compound to its surface;

- tighten the bolts of the terminal connection of the universal joint of the steering shaft;

- pour working fluid into the power steering system and remove air from it by turning the steering wheel several times;

- after installing the steering mechanism, check and, if necessary, adjust the angles of the front wheels and the position of the steering wheel.

Adjustment of a backlash between an emphasis and a lath of the steering mechanism

This adjustment is made with the steering gear removed from the vehicle. Loosen the lock nut of the rack stop adjusting screw and tighten the adjusting bolt so that the steering gear can be turned by hand with some effort without jamming.

Removal and installation of steering drafts

This operation is performed with the steering gear removed from the vehicle so as not to damage the drive gear and gear rack.

Remove the protective boot clamp from the desired side of the steering gear housing and slide the protective boot. By rotating the steering gear. fully extend the rack in the direction of the tie rod to be removed. Clamp the rail in a vice with soft lining. Loosen the tie rod.

If it is intended to reuse the removed tie rods, drive the threads of the tie rod hole with an M14x1.5 tap, then flush the threads with a suitable compound.

Before installing the left tie rod, check the dimension «A» (pic. 6-7) between the connecting surface of the link with the rail and the axis of the pin of the outer ball joint of the link. Size «A» =395 mm must remain constant. Toe adjustment of the front wheels should be done only by turning the right steering rod.

Apply a thin coat of locking adhesive to the tie rod threads.

Screw the steering rod into the rack socket and tighten the lock nut to a torque of 5.0 kgf.m. Give the steering rod the working position and slide the rack protective cover into place without twisting it. after making sure that it does not have breaks and signs of wear. Fasten the protective cover with a new clamp.

Removal and installation of the hydraulic booster pump

Removal and installation of the power steering pump is not particularly difficult. When installing a new pump, fill it with automatic transmission oil and turn the pump rotor several times by hand. Each time the pump is removed, replace the gaskets and self-locking mounting bolts, check the correct position of the pump pulley relative to the crankshaft pulley and adjust the drive belt tension.

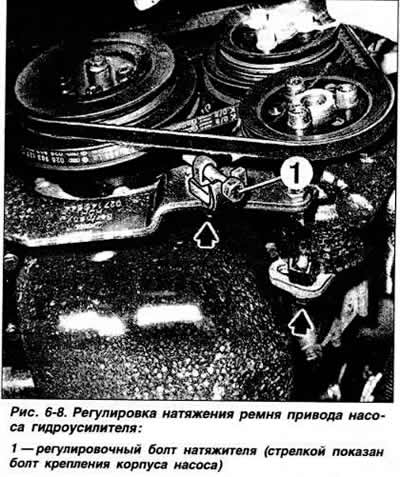

Adjusting the tension of the power steering pump drive belt

Loosen the pump housing bolt (pic. 6-8). Turn the adjusting bolt of the tensioner to achieve the desired belt tension. The deflection of the belt when pressing with your thumb on the middle of the branch between the pulleys of the pump and the crankshaft should be 5 mm.

Tighten the pump housing bolt and check the belt tension again.

Checking the discharge pressure of the hydraulic booster pump

This check is carried out using the VAG 1402 tool, which consists of a pressure gauge, a tap and a connecting hose.

Disconnect the high pressure hose from the pump and connect the hose of the VAG 1402 tool in its place through the VAG 1402/1 adapter A. Connect the high pressure hose of the hydraulic booster system to the VAG 1402 tool through the VAG 1402/2 adapter. Start the engine, check and, if necessary, restore the fluid level in the hydraulic booster reservoir. Close the valve of the VAG 1402 device and after 5 s check the pump discharge pressure on the pressure gauge. If the pressure value is beyond 75-82 kgf / cm2, replace the power steering pump. Close the tap on the pressure tester. Turn the steering wheel all the way to the left, then all the way to the right, checking the pressure on the pressure gauge in both extreme steering positions.

If the pressure does not correspond to the specified limits, at least in one of the extreme positions of the steering, replace the steering mechanism.

Visitor comments