Oil is sucked in from the engine crankcase through the oil receiver strainer and pumped by the gear oil pump into the oil filter. The purified oil enters the oil line of the cylinder block and from it is supplied to the main bearings of the crankshaft, to the connecting rod bearings, and through the channels in the cylinder head to the camshaft bearings.

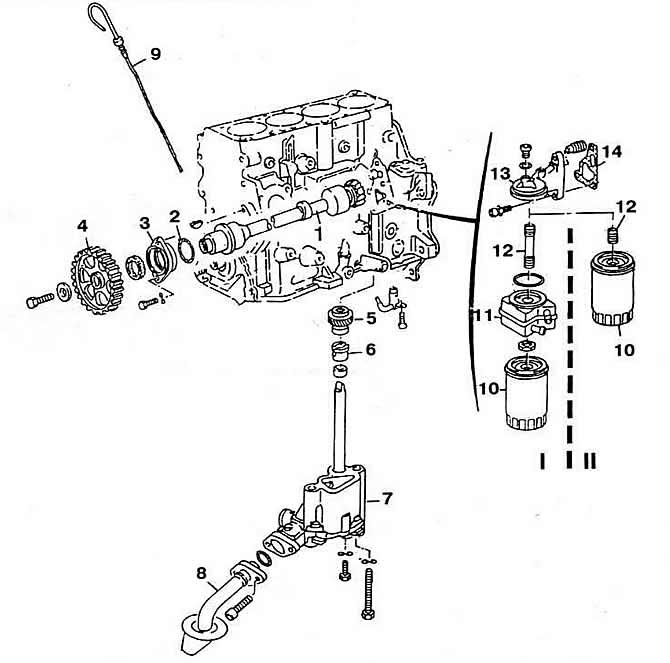

The composition of the lubrication system of engine models «RP». «ABS», «RV» and «2E» oil cooler included (pic. 2-31).

Pic. 2-31. Details of the lubrication system:

I - engine «RV»;

II - engines «EZ» and «YAR».

1 - intermediate shaft;

2 - stuffing box;

3 - guide flange;

4 - a gear pulley of an intermediate shaft;

5 - oil pump drive gear;

6 - sleeve;

7 - oil pump;

8 - oil receiver;

9 - oil dipstick;

10 - oil filter;

11 - heat exchanger;

12 - fitting;

13 - oil filter bracket;

14 - gasket.

The gear-type oil pump is driven from the intermediate shaft gear through a roller located coaxially with the ignition distributor drive shaft. A pressure reducing valve is installed in the oil pump cover.

Oil pressure in the system at an oil temperature of 80°C at idle: minimum 0.3 kgf / cm2, nominal 1.6-2.0 kgf/cm2, for engines «AGG» 1.0-2.0 kgf/cm2; at a crankshaft speed of 2000 rpm: minimum 1.8 kgf / cm2, nominal 2 kgf/cm2. Pressure reducing valve opening 5.7-6.7 kgf/cm2.

An oil filter with a replaceable filter element of the brand Mann W 719/5 is connected in series with the main oil line of the engine. The filter element is replaced at every engine oil change.

The lubrication system includes two oil pressure warning light sensors, one mounted on the cylinder block and the other on the oil filter bracket. On engines «AGG» both sensors are mounted on the heat exchanger bracket. The operation of the sensors is controlled by a special electronic unit. In the event of an emergency drop in oil pressure, an audible signal is activated.

Turn on pressure of oil pressure warning lamp, kgf/cm2:

- sensor with brown insulator when the engine is idling: < 0.3 (for engine «AGG» 0.15-0.45);

- sensor with white insulator at 2100 rpm: < 1.8.

To remove and install the oil pump, drain the oil from the crankcase. Remove the lower clutch housing cover. Install the jack under the subframe. Loosen subframe mounting bolts. Slightly lower the jack. Remove oil sump. Loosen the bolts securing the oil pump to the cylinder block. Remove oil pump.

When installing, make sure that the drive lug engages correctly with the drive shaft. Tighten the oil pump-to-cylinder block bolts. Install the oil sump. Install the lower clutch housing cover. Fill the lubrication system with engine oil.

Note. The oil pump can be removed directly on the vehicle.

Visitor comments