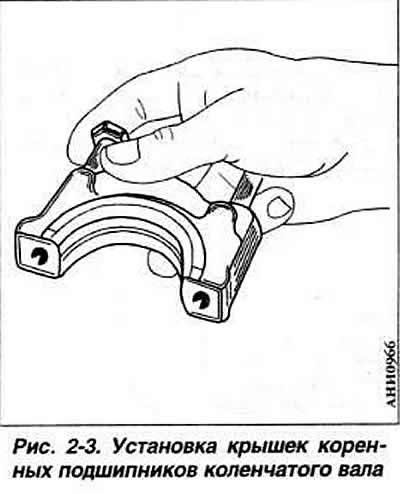

Install a clean cylinder block on the stand. Wipe the bed under the liners in the block and in the main bearing caps with a napkin. Install the liners in the sockets of the cylinder block, after wiping them and lubricating them with engine oil. The 1st, 2nd and 5th main bearing shells do not have oil grooves. The 3rd bearing shells supplied as spares have collars. On the thrust half-rings from the axial displacement of the crankshaft on the side of the cylinder block there is a protrusion directed to the liner. Wipe the main and connecting rod journals of the crankshaft with a napkin, lubricate them with engine oil and install the shaft in the cylinder block. Install the main bearing caps in accordance with the marks on their outer surfaces (pic. 2-3), wrap and tighten the bolts for fastening the covers to a torque of 6.5 kgf·m. Rotate the crankshaft. make sure it rotates freely with little effort.

Check the axial free play of the crankshaft, as indicated in subsection «Crankshaft and flywheel». Install three piston rings into the corresponding grooves in the pistons, placing their locks through 120°. Orient the lock of the upper compression ring in the plane of the axis of the crankshaft. There is a mark on the lower compression and oil scraper rings «Thor» or «Oben» («Top»), which must face upwards when the ring is installed in the groove.

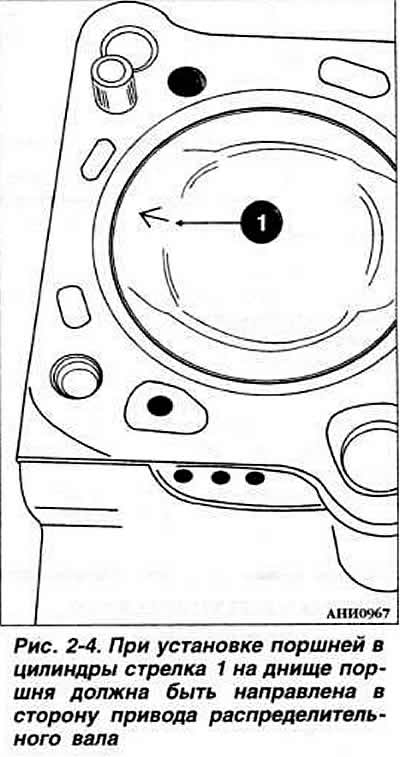

Pick up a finger to the connecting rod. Mating gap «piston pin - connecting rod bushing» - 0.017-0.021 mm. The maximum allowable in operation is 0.03-0.07 mm. Before pressing the pin, heat the piston in a water bath to a temperature of 80°C. install the assembly on the press and, using a mandrel, press the piston pin into the piston and the upper head of the connecting rod. Install the circlips into the grooves of the piston bosses. Install the pistons, orienting the arrow. embossed on the piston crown, in the sides/camshaft drive (pic. 2-4).

Lubricate the pistons and piston rings with engine oil, compress the piston rings in the grooves with a suitable mounting sleeve and insert the pistons with connecting rods into the cylinders, taking into account the instructions in fig. 2-5. Install the liners in the connecting rods and connecting rod caps in accordance with the marks made during disassembly, if worn liners are used. Lubricate with engine oil and insert the upper thrust half rings into the seat of the middle main bearing with an antifriction layer to the cheeks of the crankshaft. Lubricate and install the lower thrust washers with the middle main bearing cap. Install the connecting rods and covers on the crankshaft journals, while the sagging on the covers and the locking tabs on the liners should be directed towards the intermediate shaft. Screw on the nuts of the connecting rod bolts, then tighten them to a torque of 3.0 kgf·m and tighten them by 180°.

Install the rear oil seal holder with a new cardboard gasket. Using tool 2003/1, press the oil seal into the holder. Install the flywheel, ensuring that the surface under the clutch disc protrudes relative to the cylinder block within 30.50-32.10 mm. Tighten the fastening bolts to a torque of 10 kgf·m.

On vehicles manufactured from model year 1991, the flywheel mounting bolts must be replaced each time the flywheel is removed. Locking glue is applied to the threaded part of the bolts, and they are tightened in two steps:

- 1st reception: moment 6 kgf·m;

- Step 2: turn 90°.

On vehicles manufactured from model year 1991, the crankshaft toothed pulley bolt must be replaced with a 12-point bolt if the latter is removed. In this case, the washer is not placed under the bolt. Before installing the pulley, lubricate the threaded part and shoulder of the bolt head with engine oil. Tighten the bolt in two steps:

- 1st reception: 9 kgf·m;

- Step 2: turn 90°.

If necessary, install a spacer between the flywheel and the crankshaft flange. Install the lock washer on the flywheel with the beveled edge toward the flywheel. Apply special glue to the fastening bolts. Install the crankshaft front oil seal retainer with a new cardboard gasket. Press a new oil seal into the holder using drift 3083. Insert the intermediate shaft into the cylinder block. Install the holder with pressed-in oil seal and gasket on the intermediate shaft. Install the oil pump after checking its technical condition. Install the oil pan with a new gasket. Install the cylinder head. Install the camshaft drive belt. Install water pump.

Visitor comments