Device Features

Pierburg 2ЕЗ brand carburetor is installed on engines «EZ».

The fuel tank is plastic with a capacity of 70 liters. installed under the body floor in front of the rear axle.

Fuel used: Leaded or unleaded grade gasoline «Normal» with an octane rating of at least 95. A Bosch brand fuel filter is installed in front of the carburetor on the fuel supply hose.

Filter change interval: every 20,000 km.

The APG brand fuel pump is mechanical, diaphragm type, driven by an intermediate shaft eccentric. Fuel supply pressure with disconnected fuel drain hose 0.35-0.40 kgf/cm2.

Air filter brand Mann C31 152 with a dry paper replaceable filter element and with a device for heating the incoming air.

Carburetor Pierburg 2ЕЗ emulsion type, two-chamber, with sequential opening of throttle valves.

The carburetor has two main dosing systems of the 1st and 2nd chambers, an idle system of the 1st chamber with a transition system, a transition system of the 2nd chamber, blocking of the 2nd chamber, an economizer of power modes, an econostat, a diaphragm accelerator pump, an automatic device for starting and heating of a mixed type, which uses an electrically heated bimetallic spring and the circulation of heated liquid from the engine cooling system, and uses an air damper pneumatic drive and an electric heating device for the inlet pipeline. The carburetor has a pneumatic actuator of the throttle valve of the 1st chamber, which controls its movement in idle and forced idle modes, as well as a pneumatic actuator of the throttle valve of the 2nd chamber. At forced idle, the forced idle economizer is activated.

From model year 1989, starting with chassis number 31-K-000 001, the carburetor is equipped with a 2nd chamber throttle damper, which ensures that the damper opens only when the engine is hot.

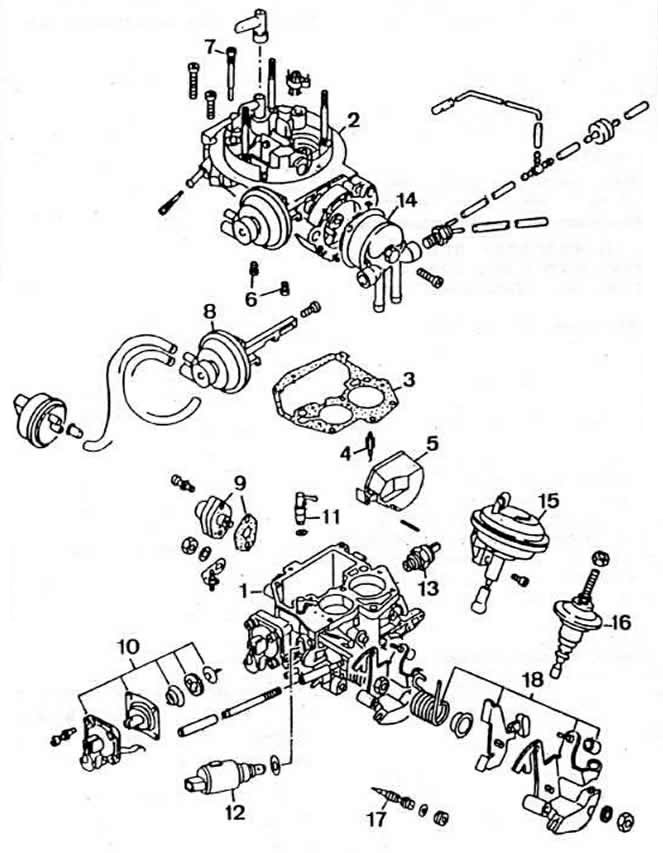

The main details of the Pierburg 2EZ carburetor are shown in fig. 2-33. The elements of the air path of the carburetor engine are shown in fig. 2-44.

Pic. 2-33. The main details of the Pierburg 2EZ carburetor:

1 - carburetor body;

2 - carburetor cover;

3 - cover gasket;

4 - needle valve;

5 - float;

6 - main fuel jets;

7 - idle fuel jet;

8 - pneumatic actuator of the air damper;

9 — economizer power modes;

10 - accelerator pump;

11 - spray accelerator pump;

12 - electromagnetic shut-off valve;

13 - heating block of the idling system;

14 - automatic starting device;

15 — throttle actuator of the 2nd chamber;

16 - throttle damper of the 2nd chamber;

17 - quality adjusting screw (composition) idle mixtures;

18 - details of the throttle actuator.

Operating principle

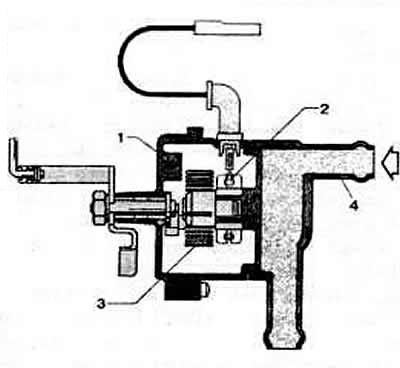

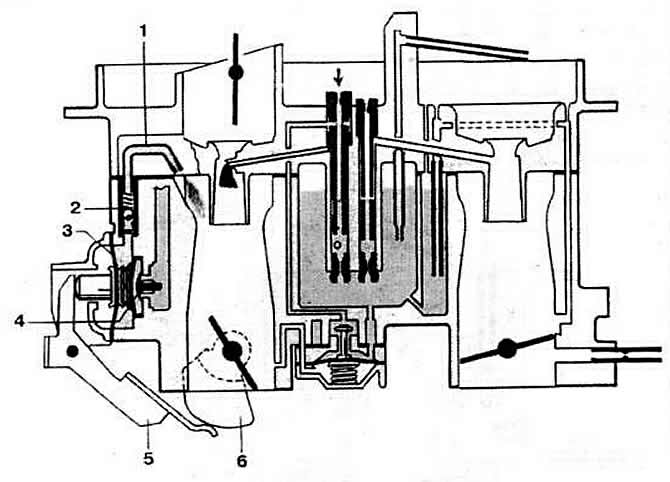

Automatic starter (pic. 2-34). Scheme of operation of the carburetor When starting a cold engine, pressing the accelerator pedal turns on the automatic starter. Initially, the air damper is completely closed. After the ignition is turned on, the heating circuit of the bimetallic spring located in the body of the automatic device is closed, and the spring begins to heat up.

Pic. 2-34. Section of the body of the automatic starter:

1—body of the automatic starting device;

2 - heating element;

3 - bimetallic spring;

4 - pipe for supplying coolant.

When starting the engine under the air damper, a significant vacuum is created. The axis of the air damper is displaced, therefore, after starting the engine, under the action of vacuum, the air damper opens slightly by a certain amount, depending on the counteracting force of the bimetallic spring. Immediately after starting the engine, in order to prevent the over-enrichment of the combustible mixture due to a pressure drop in the float chamber, the air damper is slightly opened by a certain amount by the pneumatic drive rod. This places the engine in fast idle mode, and the adjusting screw is installed on top of the profiled throttle control cam.

As the engine warms up, the engine speed decreases as follows. By briefly pressing the accelerator pedal, the fast idle adjusting screw, which is mechanically connected to the throttle valve, releases a profiled cam, which moves under the action of a bimetallic spring. After releasing the accelerator pedal, the fast idle adjusting screw is installed on the intermediate part of the profiled cam, as a result of which the throttle valve is covered and the engine speed is reduced.

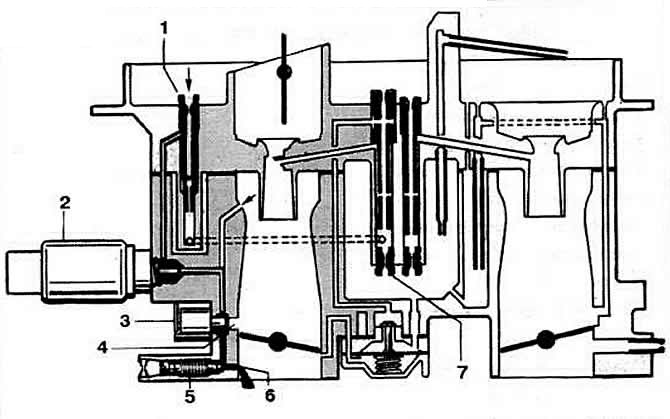

As the temperature of the heating element of the bimetal spring and the coolant rises, the tension of the bimetal spring weakens and the air damper gradually opens. When the coolant warms up to a temperature above 65°C, the power circuit of the electric mixture heating unit and the automatic starting device is opened by a thermal switch located in the inlet pipeline. At the same time, the choke valve is fully open, the fast idle adjusting screw no longer rests on the profiled throttle control cam, and the throttle valve of the 1st chamber is in the position corresponding to the normal idle mode. Idle system (pic. 2-36). When the engine is idling, the throttle valve of the 1st chamber is held in a slightly open position. Fuel from the float chamber enters through the main fuel jet of the 1st chamber into the well of the emulsion tubes and is fed to the idle fuel jet. At the outlet of the jet, the fuel mixes with the air passing through the idle air jet. The pre-prepared fuel-air mixture passes through a channel with an electromagnetic shut-off valve and is additionally mixed with air coming from the transition system channel. The finally prepared emulsion exits under the throttle valve through the hole regulated by the quality screw (composition) mixtures. The block of electric heating of the carburetor excludes its icing under adverse weather conditions.

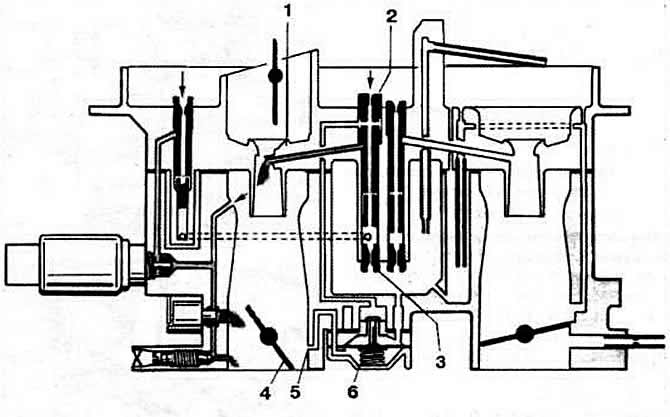

Pic. 2-36. Scheme of the idle system and the transition system of the 1st chamber:

1 - idle air jet;

2 - electromagnetic shut-off valve;

3 - carburetor electric heating unit;

4 - slot of the transition system;

5 - quality adjusting screw (composition) mixtures;

6 - outlet of the idle system;

7 - main fuel jet.

Transitional system of the 1st chamber. When you press the accelerator pedal, the edge of the throttle valve forms a crescent-shaped gap in the zone of the gap of the transition system located above the outlet of the idle system. Under the action of rarefaction, an additional amount of the fuel-air emulsion enters the first chamber through the slot of the transition system, which ensures the normal operation of the carburetor during the transition from idling to load modes.

accelerator pump (pic. 2-37). As soon as the throttle valve of the 1st chamber moves away from the idle position, the spring takes the diaphragm of the accelerator pump back, which leads to filling the pump cavity with fuel. When the throttle valve is opened, the profiled cam acts on the pump drive lever, which compresses the pump diaphragm. The inlet valve closes and the diaphragm through the ball valve and the atomizer pumps fuel into the main mixing chamber, enriching the combustible mixture.

Pic. 2-37. Accelerator pump diagram:

1 - atomizer

2 - ball discharge valve

3 - diaphragm

4 - inlet valve

5 - pump drive lever

6 - profiled pump drive cam

The performance of the accelerator pump is regulated by changing the position of the profiled cam of the pump drive.

Operation of the main dosing system of the 1st chamber at partial load (pic. 2-38). When the throttle valve of the 1st chamber is opened, the main dosing system of the 1st chamber is switched on under the action of vacuum. From the float chamber, under the action of rarefaction, the fuel through the main fuel jet of the 1st chamber enters the well of the emulsion tube, where it mixes with air leaving the main air jet opening. The resulting emulsion is sprayed by an air stream passing through a small and large diffuser. At the same time, an additional amount of the working mixture enters the mixture formation zone through the slot of the transition system of the 1st chamber and the outlet of the idle system.

Pic. 2-38. The scheme of operation of the main dosing system of the 1st chamber at partial load and the economizer of power modes:

1 - small diffuser;

2 - main air jet;

3 - main fuel jet;

4 - throttle valve;

5 - economizer vacuum intake hole;

6 - economizer power modes.

Economizer of power modes. The main dosing system of the 1st chamber includes an economizer for power modes, which operates at a certain vacuum behind the throttle valve of the 1st chamber. Fuel is taken from the float chamber through a diaphragm valve. Until. as long as the diaphragm is held by vacuum in the intake manifold, the valve is closed. At a certain opening of the throttle valve, the vacuum drops and, under the action of a spring, the valve diaphragm opens. An additional amount of fuel enters through the channels into the emulsion tube of the main dosing system of the 1st chamber. At the same time, the supply of additional emulsion through the slot of the transition system and the outlet of the idle system is gradually stopped. Transitional system of the 2nd chamber. The 2nd chamber throttle remains locked until the 1st chamber throttle opens to a certain angle. At the same time, under the action of rarefaction, the rod of the pneumatic actuator of the throttle valve of the 2nd chamber moves, providing its opening. The transition system works until the main dosing system of the 2nd chamber is turned on. Main dosing system of the 2nd chamber and econostat (pic. 2-39). As the vacuum decreases in the zone of the small diffuser, the amount of fuel-air emulsion formed in the main dosing system of the 2nd chamber increases. Full load at high speeds. close to the maximum, when the throttle valves are fully open, the econostat is turned on. Fuel from the float chamber enters the fuel pipe through the econostat jet and is sucked through the injection pipe into the secondary mixing chamber, enriching the working mixture.

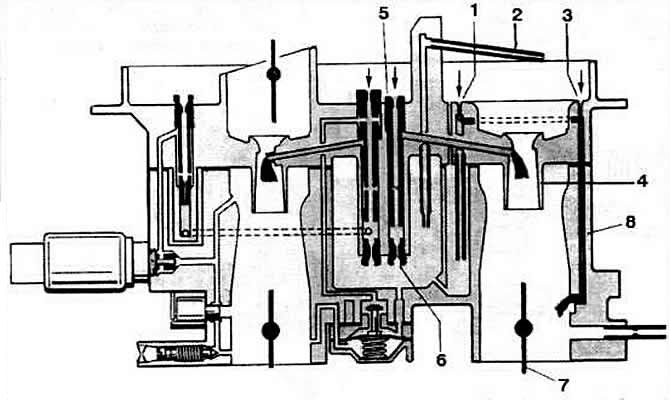

Pic. 2-39. Scheme of operation of the main dosing systems at full load and econostat:

1 - ventilation hole;

2 - econostat injection tube;

3 - air jet of the transition system of the 2nd chamber;

4 - small diffuser;

5 - main air jet of the 2nd chamber;

6 - main fuel jet of the 2nd chamber;

7 - throttle valve of the 2nd chamber;

8 - channel of the transition system of the 2nd chamber.

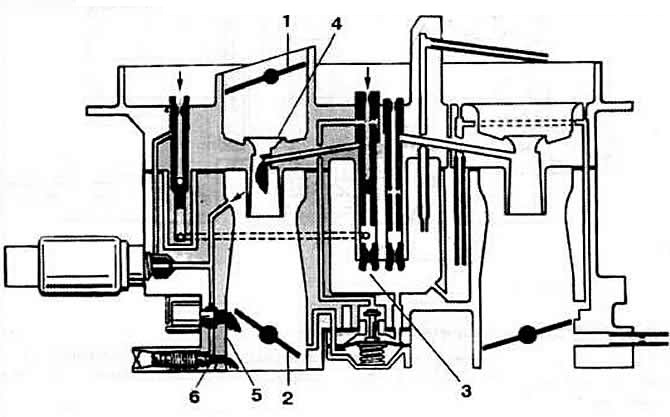

Pic. 2-35. Scheme of the carburetor when starting a cold engine:

1 - air damper;

2 - throttle valve;

3 - main fuel jet of the 1st chamber;

4 - small diffuser;

5 - slot of the transition system;

6 - the outlet of the idle system.

Visitor comments