- if the screw is turned out too far, the free travel of the fuel control lever will increase and the residual supply will become lower than required. This causes interruptions in the operation of the engine during start-up, acceleration and at low speeds, as well as the engine «shakes»;

- if the screw is too tight, the residual feed is too high. This leads to an increased idle speed, which cannot be reduced to normal.

To restore the position of the propeller, it is necessary to warm up the engine (oil temperature not less than 60°C) and turn off consumers. Remove the plug from the adjusting screw 5 (pic. 3-40) or 4 (pic. 3-41) residual feed and loosen the screw locknut.

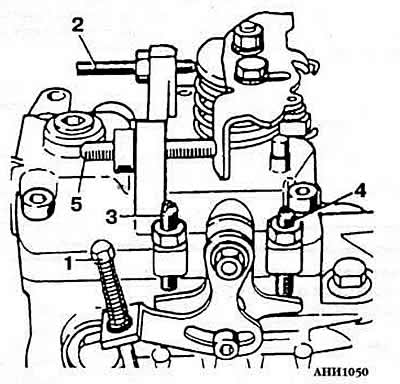

Pic. 3-40. Engine injection pump adjusting screws «1Y», «RA» and «SB»:

1 - idle adjustment screw;

2 - adjusting screw for maximum speed;

3 - restrictive screw of the minimum idle speed;

4 - limiting screw for maximum idle speed;

5 - adjusting screw for residual fuel supply.

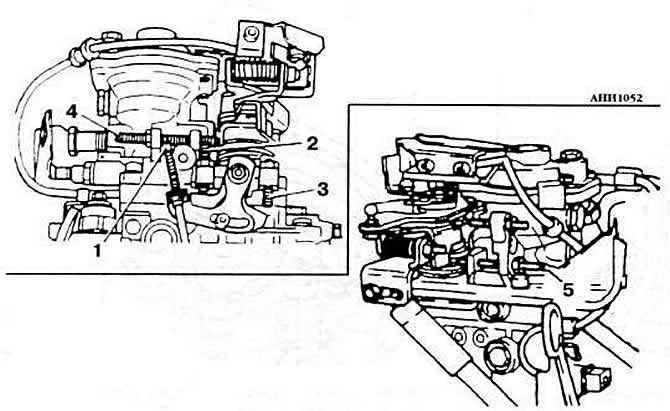

Pic. 3-41. Diesel injection pump adjusting screws «AAZ»:

1 - idle adjustment screw;

2 - restrictive screw of the minimum idle speed;

3 — the adjusting screw of the accelerated idling;

4 - adjusting screw of the residual fuel supply;

5 - adjusting screw for maximum speed.

If the residual flow is too low, tighten the adjusting screw until the crankshaft speed starts to increase, then back off the screw by half a turn.

If the residual feed is greater than normal, turn out the adjusting screw until the crankshaft speed becomes stable, then tighten the screw until the crankshaft speed begins to increase, then unscrew the screw by half a turn. After adjustment, tighten the adjusting screw locknut and install a new plug on the screw.

Visitor comments