If the clutch is to be used again, mark the position of the clutch cover on the flywheel.

Loosen the bolts securing the clutch cover to the flywheel and remove the cover assembly with the driven disk. This releases the clutch disc. Thoroughly clean clutch parts. Using a straightedge and a feeler gauge, check the flatness of the working surface of the pressure plate.

Check the degree of wear of the pressure spring in the place of contact with the clutch release bearing. Using an indicator, check the degree of wear of the friction linings of the driven disk at a distance of 2.5 mm from the circumference of the disk. Clean the friction surface of the pressure plate. Cleaning of other parts of the clutch is not required, because. they are protected from corrosion.

Check the condition of the splines in the hub of the driven disk and on the input shaft of the gearbox, clean the splines and lubricate with a thin layer of grease based on molybdenum disulphide.

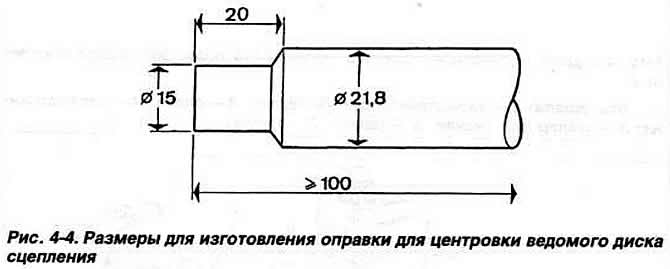

Install the clutch, positioning the driven disc with the protruding part of the hub towards the pressure plate, and center the disc relative to the flywheel with a mandrel (pic. 4-3 and 4-4), simulating the splined end of the input shaft of the gearbox.

Tighten the clutch cover mounting bolts crosswise to 2 kgf·m. Remove trim. Check the condition of the clutch release bearing and replace it if necessary.

Apply a light coat of grease to the sliding surface of the clutch release bearing in the guide bush. Install the gearbox as indicated in the subsection «Removal and installation of a transmission».

Note. On an AFN engine, when replacing the driven plate or clutch cover, change the position of the part 3067 support.

Visitor comments