Remove the clamp securing the protective cover (pic. 4-83). Remove the clamp securing the cover to the shaft and wrap the cover. Remove the hinge cover with a screwdriver or other suitable object inserted under it, acting as a lever. If the cover does not come off, insert a screwdriver from the opposite side and try again. Remove grease from hinge parts. Remove the O-ring from the groove.

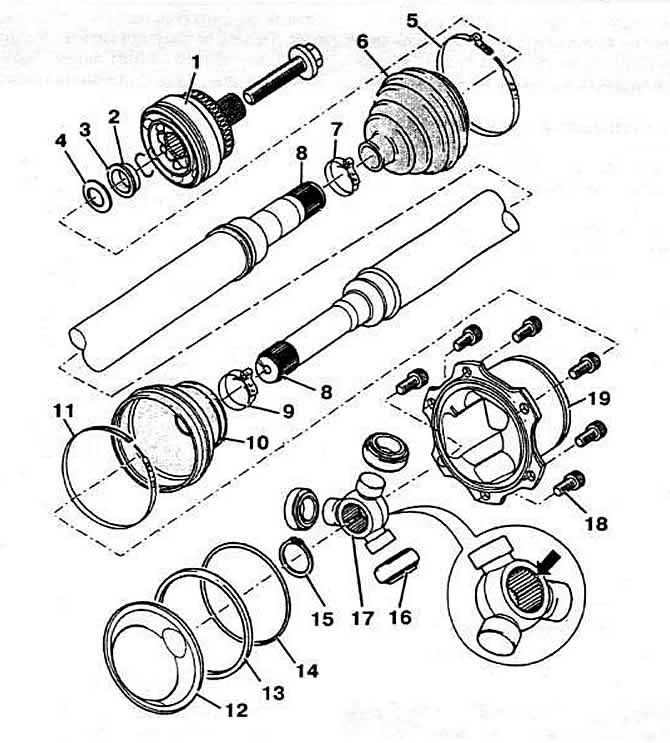

Pic. 4-83. Wheel Drive Shaft Details:

1 - outer hinge;

2 - retaining ring;

3 - support ring;

4 - spring washer;

5, 7, 9, 11 - cover clamp;

6, 10 - protective cover;

8 - wheel drive shaft;

12 - cover;

13 — a sealing ring of rectangular section;

14 — o-ring of circular cross-section;

15 - retaining ring;

16 - rollers;

17 - clip;

18 - bolt with an internal multi-faceted turnkey recess;

19 - hinge body.

When removing parts, put alignment marks on them, otherwise increased noise of the ball joint may occur when driving.

Remove the rubber ring from the groove. While holding the hinge housing, remove the wheel drive shaft from the vise, being careful to remove it. so that the hinge rollers do not fall out of the cage. Keeping the wheel drive shaft in a vertical position with one hand, slowly move the joint housing with the other hand. Use a felt-tip pen to mark the position of the rollers relative to the cage. Remove hinge rollers and place on a clean surface. Remove retaining ring. Install the wheel drive shaft in the press. holding the shaft. compress the hinge clip from it. Remove the hinge housing from the shaft together with the boot. Clean shaft and joint housing.

To assemble, clamp the wheel drive shaft in a vice with soft jaws. Put on the shaft a clamp of small diameter for fastening the protective cover of the hinge. Put a cover on the shaft. Put the hinge housing on the shaft. The chamfer on the hinge cage must face the shaft. Put the hinge holder on the shaft according to the previously applied marks, then press it in until it fails. Install the retaining ring, paying attention to its correct position. Install the rollers on the holder according to the previously applied marks. Put the hinge body on the clip with rollers and hold it. Remove the wheel drive shaft from the vise and clamp the hinge housing with a vise.

Install a new square O-ring from the repair kit into the groove. The tightness of the connection between the hinge and the flange of the differential output shaft is ensured directly by the shape of the rectangular section of the sealing ring. Because of this, the hinge cover does not need to be installed.

Place 90 g of grease for CV joints, which is part of the repair kit, into the constant velocity joint. Apply 90 g of grease to the back of the hinge. Reinstall the hinge cover. Install the flexible boot clamp. Tighten the small diameter clamp with pliers.

Visitor comments