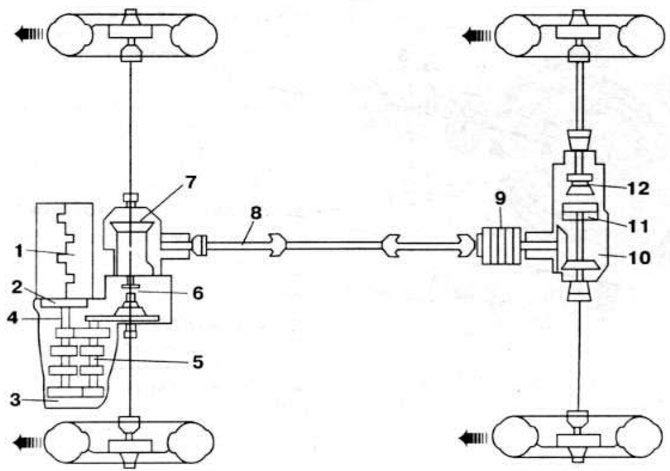

Pic. 18. Kinematic diagram of the car transmission "Passat GT 1.8 G60 Syncro»: 1 - engine; 2 - clutch; 3 - gearbox; 4 - input shaft; 5 - secondary shaft; 6, 12 - differential; 7 - transfer case; 8 - cardan shaft; 9 - viscous coupling; 10 — a reducer of back wheels; 11 - freewheel.

Transfer case oil

Crankcase filling capacity 0.5 l. Applicable oil: transmission oil, viscosity grade SAE 80 or SAE 75W90. quality class API GL 4. During the entire service life, no oil change is required.

Rear axle final drive oil

Crankcase filling capacity 0.7 l. Applied oil: transmission. viscosity grade SAE 80 or SAE 75W90, quality grade API GL 4. No oil change is required during the entire service life.

Tightening torques of the main threaded connections, kgf·m

Bolts for fastening wheel drives to flanges: 4.5.

Bolts for fastening the transfer case to the gearbox: 4.0.

Bolts for fastening the suspension bracket to the transfer case and to the engine: 4.0.

Bolts for fastening the intermediate supports of the cardan shaft to the body: 2.5.

Bolts for fastening the middle part of the cardan shaft to the front and rear parts of the cardan shaft: 4.0.

Bolts for fastening the flexible coupling to the cardan shaft: 4.5.

Assembly and disassembly of the transfer case

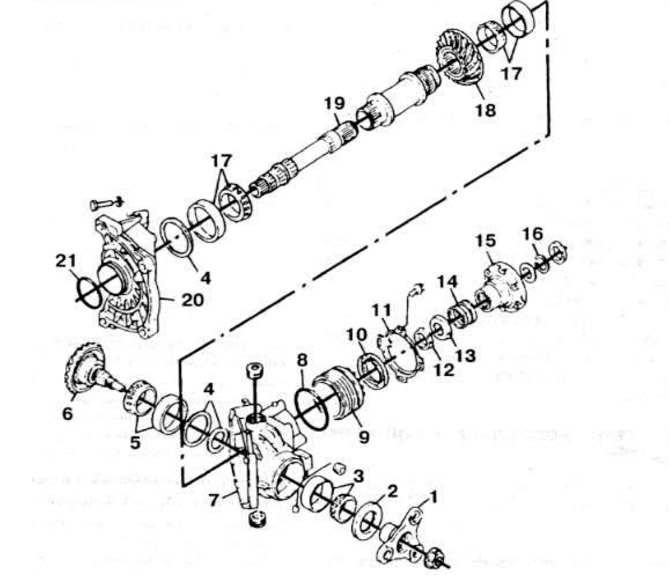

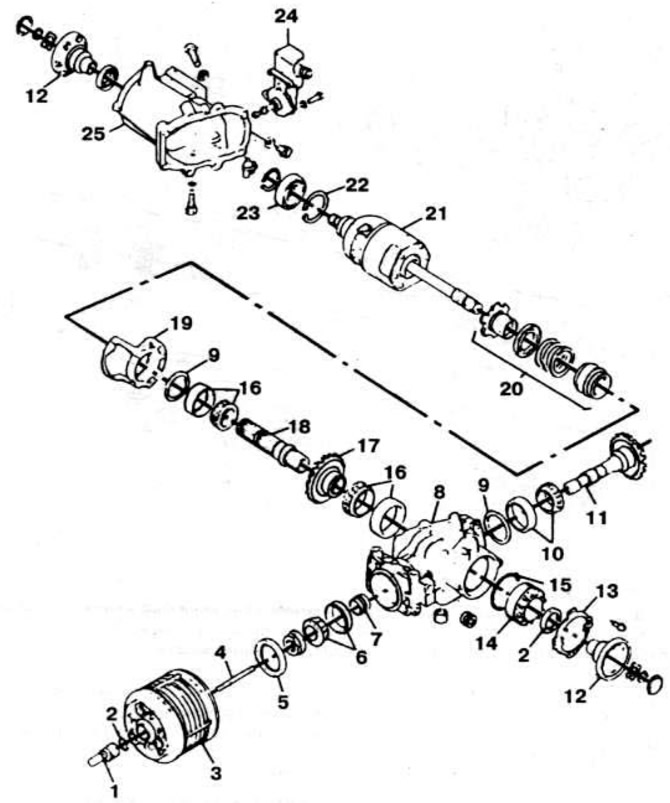

The scheme of the transfer box is shown in fig. 19.

Pic. 19. Transfer box: 1 - drive shaft drive flange; 2, 10 - stuffing box; 3 - rear roller bearing of the driven gear; 4 - adjusting ring; 5 - front roller bearing of the driven gear: 6 - driven gear: 7 - transfer case housing; 8, 21 - sealing ring; 9 - adjusting nut; 11 — a lock ring of an adjusting nut; 12 - conical bushing; 13 - thrust washer; 14 - pressure spring; 15 — a flange of a drive of the right forward wheel; 16 - retaining ring; 17 - tapered roller bearing of the drive shaft; 18 - drive gear; 19 - drive shaft; 20 - crankcase cover.

To disassemble, remove the transfer box. Loosen the propshaft drive flange bolt and remove it. Remove the right front wheel drive flange. Remove the locking ring of the adjusting nut. Unscrew the adjusting nut, noting its position relative to the transfer case body. Loosen the transfer case housing connector bolts. Remove the transfer case drive shaft. Remove drive gear with input shaft. Pull out the driven gear.

To assemble, install the driven and driving gears with the input shaft in the transfer case housing. Install driveshaft drive flange. Lubricate the plane of the crankcase gasket with sealant. Reinstall the crankcase cover and tighten the bolts to a torque of 2.5 kgf·m. Tighten the adjusting nut to the mark made during disassembly. Install the lock ring on the adjusting nut. Install the drive shaft. Install the right front wheel drive flange, cone ring, compression spring and thrust washer. If necessary, use tool VW 391. Install the spring washer and circlip of the right front wheel drive flange. Install the propshaft drive flange bolt with a hex head, lubricating its threads with D6 locking adhesive. and tighten it with a torque of 3.0 kgf·m.

Removal and installation of cardan transmission

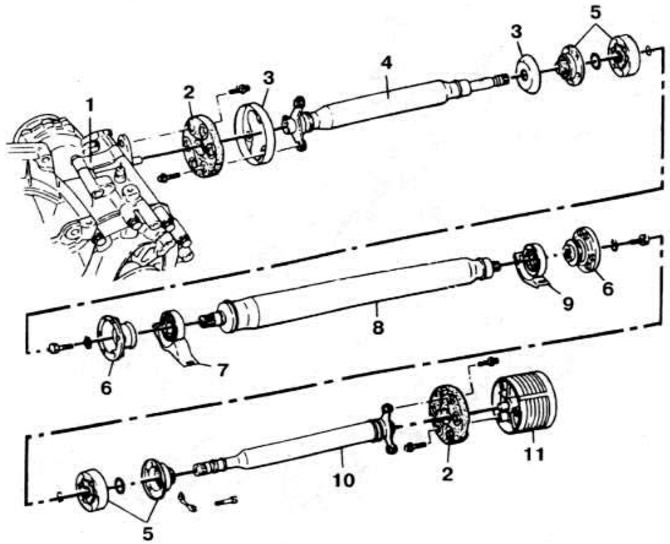

The cardan transmission device is shown in fig. 20.

Pic. 20. Cardan gear: 1 - gearbox with transfer case: 2 - elastic coupling; 3 - protective cover; 4 - front propeller shaft; 5 - hinge of equal angular velocities; 6 - flange; 7 - front intermediate support; B - middle cardan shaft; 9 - rear intermediate support; 10 - rear driveshaft; 11 - viscous coupling.

To remove, disconnect the fastening of the front part of the muffler and remove it. Remove heat shield under propshaft. Loosen the propeller shaft rear intermediate support bolts. Mark the position of the rear part of the driveshaft and disconnect it from the constant velocity joint. Unscrew the bolts securing the rear of the cardan shaft to the viscous coupling. Move forward the middle part of the cardan shaft. Remove the rear driveshaft. Loosen the three bolts securing the front driveshaft to the flexible coupling. Unscrew the three bolts securing the flexible coupling to the transfer case flange. Mark the position of the propshaft in relation to the flexible coupling. Loosen the bolts securing the front intermediate support to the body. Slightly pull the cardan shaft and unscrew the bolts securing the cardan shaft to the flexible coupling. Remove the propeller shaft towards the rear of the vehicle, slightly moving the exhaust pipe to the side.

The propeller shaft is installed in the reverse order of removal.

Removal and installation of viscous coupling

When working, be guided by Fig. 20, 21 and 22.

To remove, disconnect the rear part of the cardan shaft, marking its position relative to the middle part. Loosen the viscous coupling centering nut using a spark plug wrench. Hold the viscous coupling with a mounting spatula. Unscrew the stabilizer of the support bracket and press it down. Remove viscous coupling.

To install, tighten the centering nut to a torque of 4.5 kgf·m. Install the rear part of the propeller shaft in accordance with the marks made during disassembly.

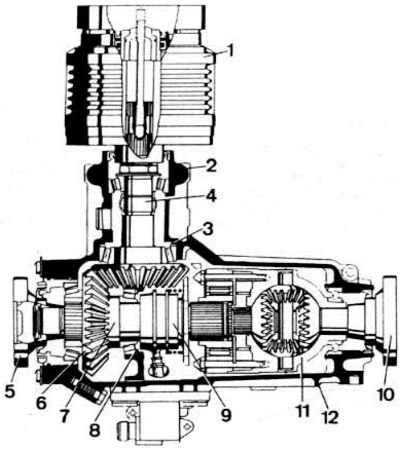

Pic. 21. Rear wheel final drive device: 1 - viscous coupling; 2 - gearbox housing; 3 - adjusting ring of the drive gear; 4 - drive gear; 5 - flange of the left output shaft of the differential; 6 - driven gear of the main gear; 7 - left output shaft of the differential; 8 — an adjusting washer of bearings of the main transfer; 9 - freewheel; 10 - flange of the right output shaft of the differential; 11 - differential.

Pic. 22. Details of final drive and rear wheel differential: 1 - mounting sleeve; 2, 5 - stuffing box; 3 - vkkomufta; 4 - pin; 6 - front roller bearing of the drive gear; 7 - spacer sleeve; 8 - gearbox housing; 9 - adjusting ring: 10 - rear roller bearing of the drive gear; 11 - drive gear; 12 - flange of the left output shaft of the differential; 13 - lock washer; 14 - adjusting nut; 15 - gasket; 16 - roller bearing of the driven shaft; 17 - driven gear; 18 - input shaft; 19 - clip; 20 - mechanism for blocking the freewheel; 21 - differential with freewheel; 22 - retaining ring; 23 - ball bearing differential box; 24 - pneumatic drive for blocking the freewheel; 25 - differential housing.

Replacement of an epiploon of a flange of a drive of a shaft of a forward wheel

Disconnect the front wheel drive shaft from the flange. Remove retaining ring and flange washer. Remove flange. If necessary, use tool VW 391. Use a screwdriver to remove the oil seal. The gland is installed in the reverse order.

Removal and installation of the main transfer and differential of back wheels

The device of the main transfer and differential is resulted on fig. 21 and 22.

Remove the viscous coupling and plug the hole in its housing. Disconnect the right and left rear wheel drive shafts from the flanges. Disconnect the pipe from the freewheel lock pneumatic actuator. Disconnect the rear suspension elements from the gearbox housing. Place a jack under the gearbox housing. Loosen the screws securing the gearbox housing. Lower the gearbox housing by 20 cm and disconnect the pneumatic drive hose. Remove main gear from vehicle.

The unit is installed in the reverse order.

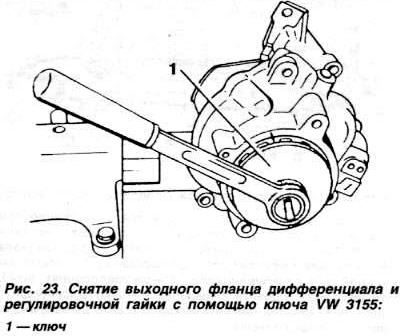

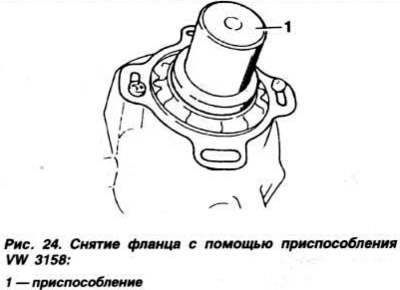

Dismantling and assembly of differential of the main transfer of back wheels

For disassembly, install the unit without viscous coupling on a stand. Drain oil from crankcase. Loosen the fixing of the reducer pneumatic actuator, turn it by 90°and remove it from the reducer housing. Remove the flange of the left differential output shaft (pic. 23) from the adjusting nut. Remove the lock washer of the adjusting nut. Unscrew the adjusting nut, having previously marked its position relative to the housing. Loosen the crankcase mounting bolts. Remove the rear differential housing. Remove the input shaft with the driven gear, making sure that the retainer balls do not fall out.

Assembly is carried out in the reverse order of disassembly.

Assembly is carried out in the reverse order of disassembly.

Removal and installation of the freewheel

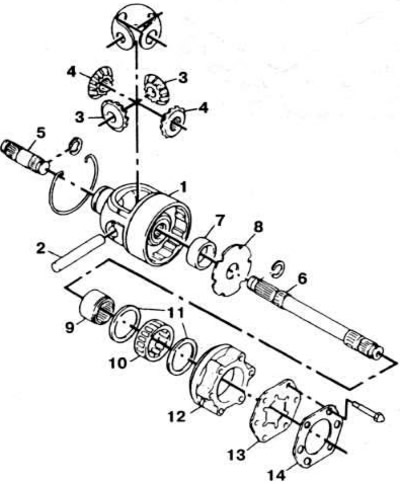

The freewheel device is shown in fig. 25.

Pic. 25. Parts of rear wheel differential and freewheel: 1 - differential box; 2 - axis of the satellites; 3 - satellites; 4 - side gears; 5 - right output shaft of the differential; 6 — left output shaft of the differential; 7 - spacer sleeve; 8 - disk with external gearing; 9 - freewheel hub; 10 - roller cage freewheel; 11 - thrust washer; 12 - freewheel housing; 13 - disk with internal gearing; 14 - locking plate.

To remove, secure the differential housing in a vice with soft jaws. Remove the retaining ring using a lever. Remove the freewheel lock plate by unscrewing the bolts first. Remove the internal gear. Remove freewheel. Remove the left differential output shaft, external gear and spacer. Remove thrust washers. Remove the freewheel hub by turning it to the right. Remove the freewheel lock housing.

To install, place the lock mechanism housing into the freewheel housing. Install the freewheel hub by turning it to the right. Install thrust washers. Install the spacer and external disc, aligning the holes in it with the threaded holes in the differential housing. Install left differential output shaft. Reinstall the freewheel, secure the disc with internal gearing. Install a new lock plate and bend its two tabs onto the disc with internal engagement. Tighten the lug bolts to a torque of 2.0 kgf·m. Install retaining ring.

Checking the freewheel

Raise the vehicle. Slowly turn the rear wheels in the forward direction. The wheels must turn freely. without noticeable resistance. Rotate the rear wheels in the direction of travel to the rear. In this case, the transmission must set the front wheels in motion.

Freewheel Lock Check

Run the engine for about half a minute. Raise the vehicle. Switch on the ignition, engage reverse gear and depress the clutch pedal. Rotate rear wheels in forward and reverse direction. In this case, the wheels should rotate with noticeable resistance and the transmission should rotate the front wheels while turning the rear wheels in both directions.

Visitor comments