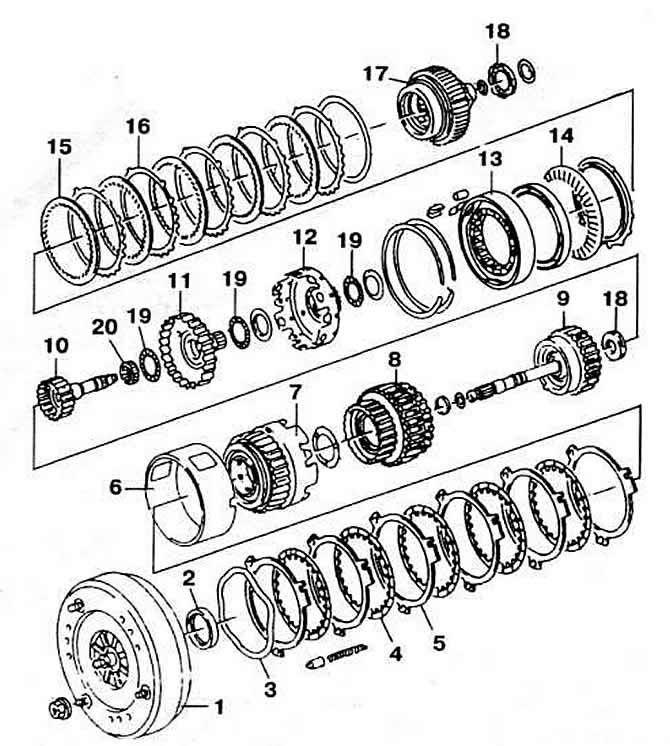

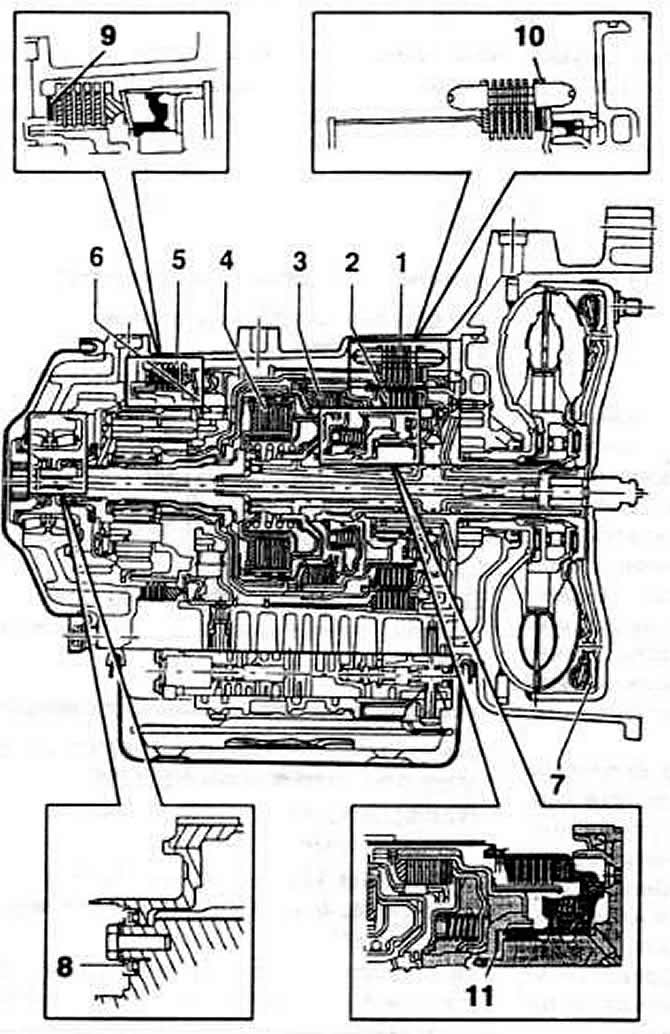

Pic. 4-58. Details of automatic transmission type 01M:

1 - torque converter;

2 - stuffing box;

3 - retaining ring;

4, 15 - disks with internal gearing;

5, 16 - disks with external gearing;

6, 12 - drum;

7 - reverse clutch;

8, 9 - forward clutches;

10 - input shaft;

11 - crown gear;

13 - freewheel 1st gear;

14 - pressure spring;

17 — carriage satellites;

18 - bearing;

19 - thrust needle bearings;

20 - radial needle bearing.

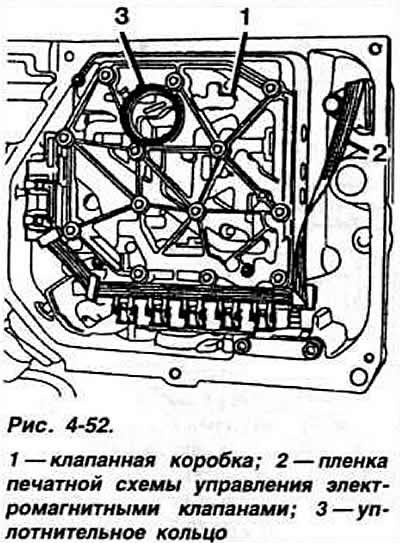

Depending on the information received, the control unit issues commands to the solenoid valves of the valve box (pic. 4-52), electromagnetic selector lever lock (with the ignition on) and starter interlock relay (in any gear).

The control unit works according to fuzzy logic (or with deliberate inaccuracy), i.e. taking into account all intermediate states that occur between the main states (0-1 in binary logic).

Thanks to this, the operation of the hydromechanical gearbox adapts to the driving style. engine characteristics and driving conditions (wheel rolling resistance). Gearbox has no «economical» and «sports» operating modes.

Electronic control unit 68-valve.

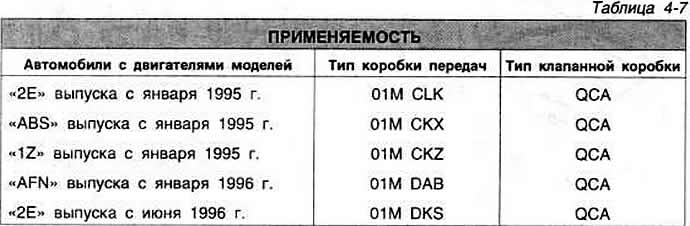

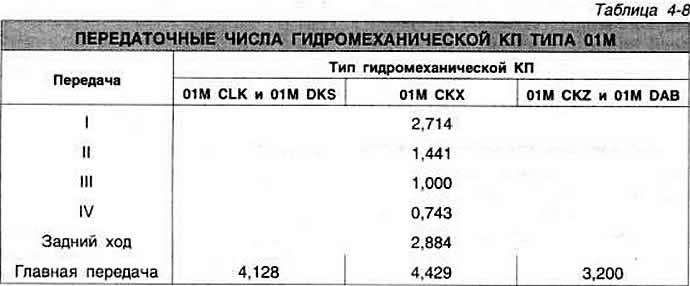

Applicability of gearbox types and their gear ratios are shown in tables 4-7 and 4-8.

Pic. 4-60. Section view of the hydromechanical gearbox type 01M and the installation location of the adjusting rings:

1 - brake II and IV gears;

2 - reverse clutch;

3 - clutch for switching on I, II and III gears;

4 - clutch for inclusion of III and IV gears;

5 - reverse brake;

6 - freewheel;

7 - direct clutch;

8 — an adjusting ring of a cup of satellites;

9 — an adjusting ring of a brake of a back gear F1;

10 - adjusting ring brake II and IV gears F2;

11 - adjusting ring for clearance between clutches E1 and E2.

Visitor comments