Fasten the stand with the indicator to the clutch housing (pic. 4-34) and install the indicator leg on the end of the output shaft.

Moving the secondary shaft up and down in the axial direction and without turning it, note the axial movement on the indicator «X» secondary shaft.

Calculate required thickness «T» adjusting ring according to the formula: T \u003d 0.65 + 0.20 + X, where 0.20 mm is the value of the required bearing preload.

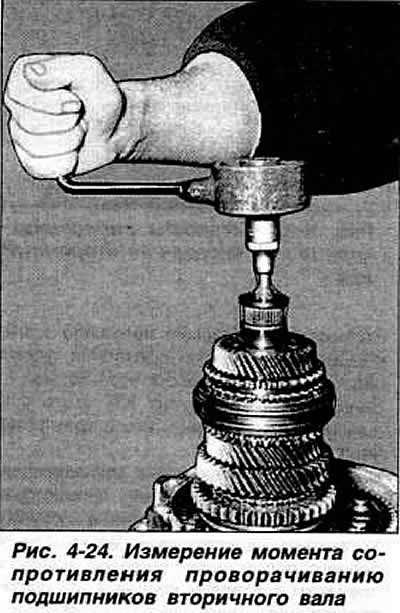

Install an adjusting ring of the thickness found in this way under the outer ring of the bearing, install the output shaft with bearings, pre-lubricating them with oil, and check the moment of resistance to turning the output shaft bearings (pic. 4-24), which should be 0.3 kgf·m for run-in bearings, and 1.3-1.8 kgf·m for new bearings.

Visitor comments