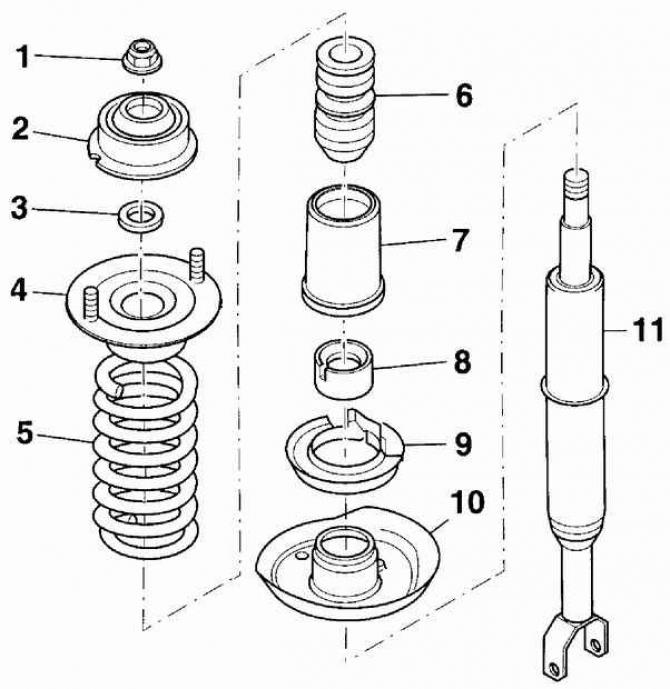

Shock absorber elements

- 1 - collar nut 50 Nm,

- 2 - bearing,

- 3 - washer,

- 4 - upper spring plate,

- 5 - cylindrical twisted spring,

- 6 - emphasis. It is installed in the upper plate of the spring,

- 7 - protective cover,

- 8 - protective cover,

- 9 - spring support,

- 10 - lower spring plate,

- 11 - shock absorber

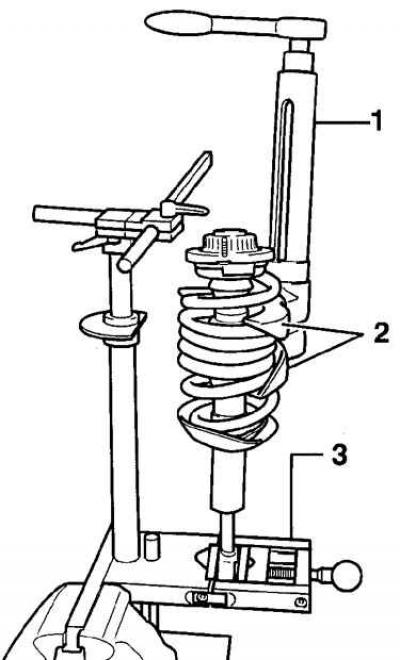

Suspension strut spring compressor

- 1 - a device for compressing the spring,

- 2 - device grips,

- 3 - a device for mounting the shock absorber

Disassembly

1. Secure the front suspension strut in a soft jaw vise and, using the special tool, compress the spring so that it moves away from the top of the strut, see fig. Shock absorber spring compression tool.

When using a special device for spring compression, make sure that the coils of the spring are securely gripped and the spring is compressed from opposite sides. The spring has a very high compression force, so use only a very reliable tool. Never tie the spring with wire.

2. Secure the shock absorber rod against turning with a wrench and, using the second spanner wrench, unscrew the central shock absorber rod mounting nut.

3. Remove the bearing, washer and upper spring plate from the shock absorber rod.

4. Remove the spring together with the spring compressor.

5. Remove the protective cover (1) and spring support (2). Using a plastic hammer, knock the lower spring plate upwards (3).

Installation

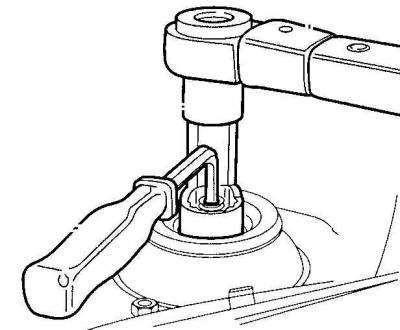

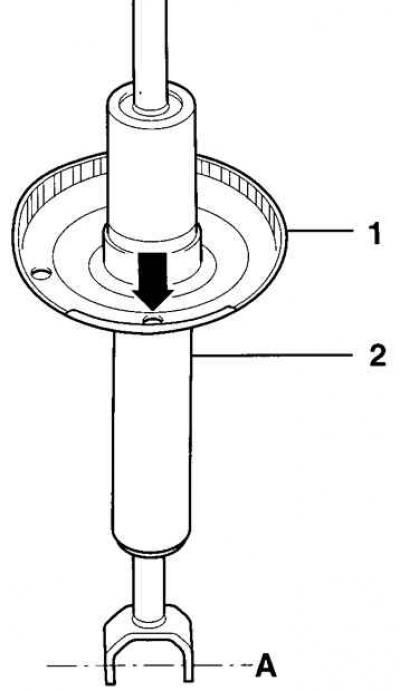

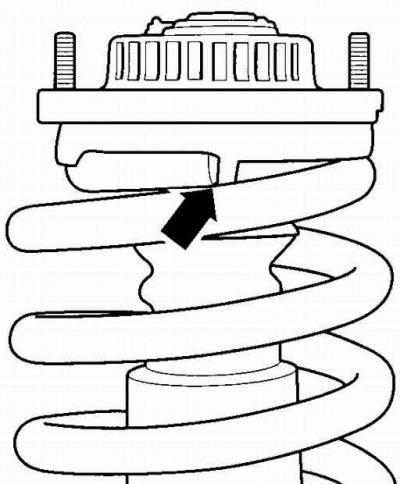

Correct hole position (arrow) when installing the lower spring plate on the shock absorber

- 1 - lower spring plate,

- 2 - shock absorber,

- A - the axis of the fork of the lower mounting of the shock absorber

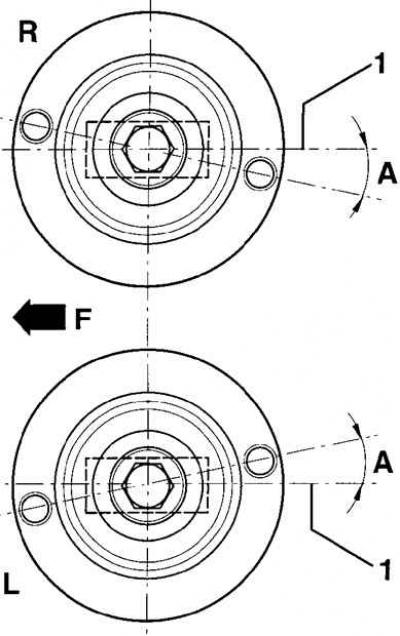

The correct location of the upper spring plate

- F - in front of the car,

- R - right suspension strut,

- L - left suspension strut,

- A - 11°±2 minutes,

- 1 - axis of the lower mounting of the shock absorber

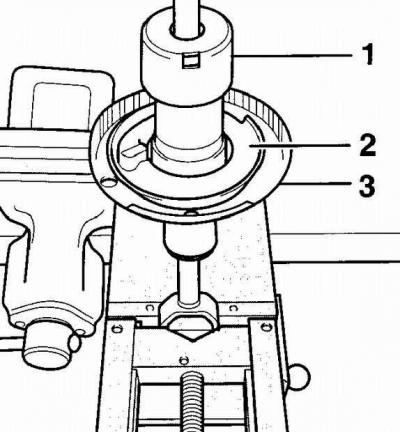

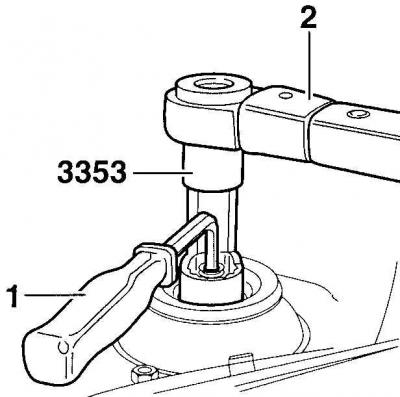

Tightening the shock absorber rod nut

- 1 - key to hold the shock absorber rod from turning,

- 2 - torque wrench for tightening the shock absorber rod mounting nut

Warning: When installing, it is necessary to use springs with the same technical characteristics on the same axle of the car (with the same color marking).

1. Check the shock absorber for signs of damping fluid leaks. Check the entire length of the damper rod for pitting. Check the shock absorber housing for mechanical damage. Set the shock absorber to a vertical position and check its operation by moving the shock absorber rod through its full stroke. Also check the operation of the shock absorber by moving the shock absorber rod up and down a distance of 50–100 mm. In all cases, the shock absorber rod should move smoothly with perceptible resistance. If the shock absorber rod moves jerkily or there are mechanical damages, the shock absorber must be replaced.

2. Fix the shock absorber in a vice with soft jaws.

3. Install the lower spring plate on the shock absorber, while the hole in the spring plate should be perpendicular to the hole in the shock absorber lower mounting yoke (see fig. Correct hole position (arrow) when installing the lower spring plate on the shock absorber). The deviation of the hole in the lower plate of the spring from the perpendicular position should be no more than±2°.

4. Install the spring support and protective cover.

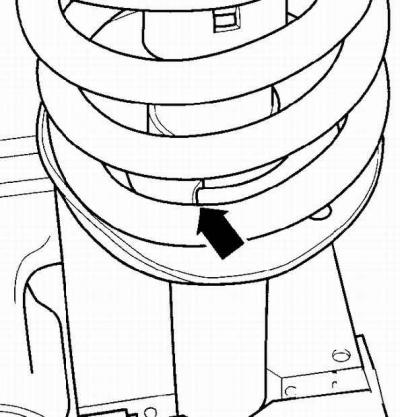

5. Install the coil spring so that its lower end is correctly located in the lower spring plate.

6. Install the upper spring plate in such a way that the axis passing through the mounting threaded holes is located at an angle of 11°with respect to the axis of the lower suspension strut mounting (see fig. The correct location of the upper spring plate). Keep in mind that the mounting of the upper spring plate for the left and right shock absorber struts are different.

7. While holding the shock absorber rod from turning, screw on a new shock absorber rod collar nut and tighten it to 50 Nm, see fig. Screwing the shock absorber rod nut.

8. Carefully remove the spring compressor.

9. Check that the upper coil of the spring is correctly located on the upper spring plate.

10. Install the suspension strut in the car.

Visitor comments