Warning: Light alloy rims are protected against corrosion by clear varnish. Be careful not to damage the lacquer finish. If the coating is damaged, cover the disc with a layer of varnish.

Warning: Zinc plated wheel bolts can only be used on stamped steel rims.

Warning: Light alloy rims are only attached with chrome wheel bolts that have a tapered rotating washer. This washer, mounted under the head of the bolt, protects the disc surface when the bolts are tightened.

Warning: Before screwing in, do not lubricate the wheel bolt threads.

Warning: Standard wheel bolts are M14x1.5x27.5. Turnkey head size 17 mm.

Warning: Tighten the wheel bolts uniformly in several stages in a diagonal sequence.

Warning: Wheel bolt torque 120 Nm.

Order of execution

1. Remove the wheel trim. To do this, use the pry bar and wire clamp from the tool kit. The wire clip is installed on the opening of the cap or on the edge. Pass the pry bar through the bracket and pull the pry bar away from the wheel to remove the cap.

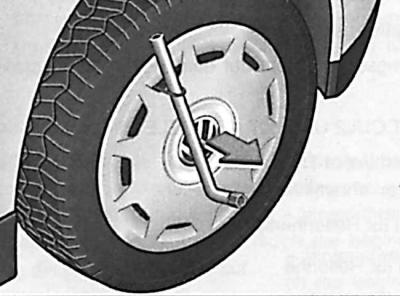

2. With the vehicle on the ground, apply the handbrake and loosen the wheel bolts.

3. Raise the appropriate side of the vehicle and secure it on stands.

4. Remove the top wheel bolt.

5. Screw the dowel pin in its place. The use of a locating pin facilitates the installation of the spare wheel.

6. For exclusion "sticking" wheel discs to the hub, before installing the wheel, apply a thin layer of grease to the shoulder of the hub centering the wheel disc.

Visitor comments