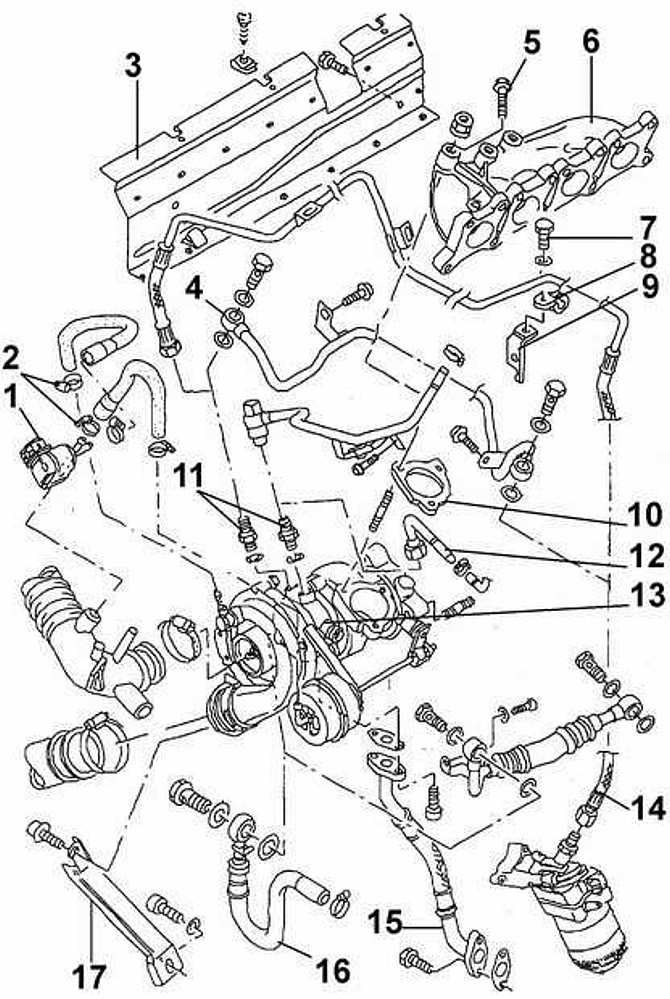

1.8-I AEB engine turbocharger

- 1 - valve,

- 2 - collar,

- 3 - air deflector,

- 4 - oil supply pipeline,

- 5 - bolt M10x50,

- 6 - exhaust manifold,

- 7 - bolt M6x12,

- 8 - clamp,

- 9 - plate,

- 10 - gasket,

- 11 - fitting,

- 12 - pipe for coolant,

- 13 - turbocharger,

- 14 - oil supply pipeline,

- 15 - oil return pipeline,

- 16 - pipe for coolant,

- 17 - bracket

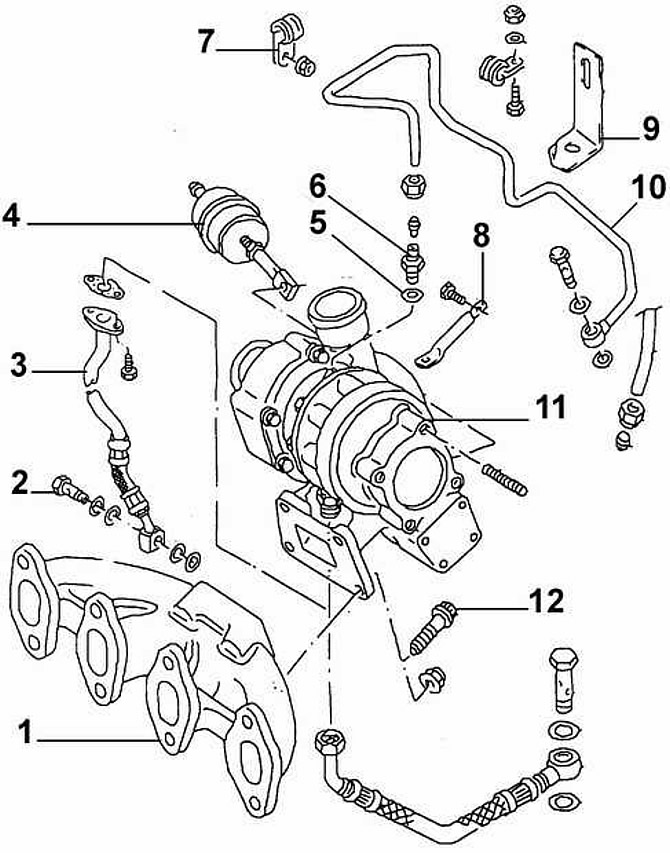

Diesel Turbocharger 1.9 AHU

- 1 - exhaust manifold,

- 2 - connecting bolt,

- 3 - oil return pipeline,

- 4 - pressure valve,

- 5 - sealing ring,

- 6 - fitting,

- 7 - clamp,

- 8 - bracket,

- 9 - plate,

- 10 - oil supply pipeline,

- 11 - turbocharger,

- 12 - bolt

On diesel engines and four-cylinder gasoline engines with a power of 150 hp turbocharger installed, see fig. Turbocharger engine 1,8-I AEB.

The power that an engine can develop depends on the amount of air and fuel that enters the engine's cylinders. To increase engine power, it is necessary to increase both the amount of air supplied and the fuel. Supplying more fuel will have no effect until there is enough air for combustion, otherwise there will be an excess of unburned fuel, which leads to overheating of the engine, which also smokes a lot. To increase the amount of air supplied to the engine, a turbocharger is used, which compresses the air supplied to the combustion chamber.

The turbocharger consists of a centrifugal air pump and a turbine connected by a common rigid axis to each other. Both of these elements rotate in the same direction and at the same speed. The energy in the exhaust gas flow, which is not used in conventional engines, is converted here into torque, which drives the turbocharger. Exhaust gases leaving the engine cylinders are at high temperature and pressure. They accelerate to high speed and come into contact with the turbine blades, which converts their kinetic energy into mechanical energy of rotation. This energy conversion is accompanied by a decrease in the temperature of the exhaust gases and their pressure. The turbocharger sucks air through the air filter, compresses it and delivers it to the engine cylinders. The amount of fuel that can be mixed with air can be increased, allowing the engine to develop more power.

To lubricate the turbocharger, engine oil is supplied under pressure through a special pipeline.

Since the turbocharger operates at high speeds, care and cleanliness must be observed to prevent contaminants from entering the turbocharger and damaging it.

Warning: Before disconnecting any elements from the turbocharger, thoroughly clean them of dirt. To protect against contamination, place the elements removed from the turbocharger in a sealed container. To prevent dirt from entering the turbocharger, close the air passages of the turbocharger.

A heat exchanger is installed between the turbocharger and the intake manifold, which reduces the temperature of the air supplied to the engine. Cooling the air increases the power of the engine, as the oxygen content in cold air increases due to its higher density.

On vehicles with AFN and AHH engines, engine power is increased by using a controlled turbocharger. The controlled turbocharger has adjustable guide vanes which are controlled by a solenoid valve and a vacuum unit. In this regard, in all operating modes of the engine, the turbocharger creates an optimal boost pressure, which increases the engine torque.

Visitor comments