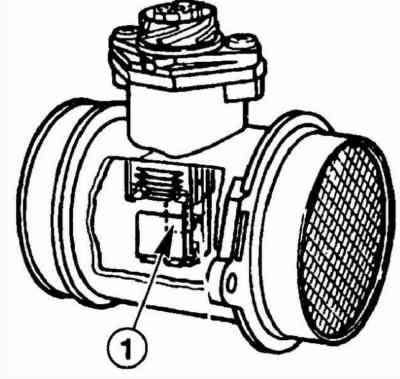

Conductor strip location (1) in the air flow meter

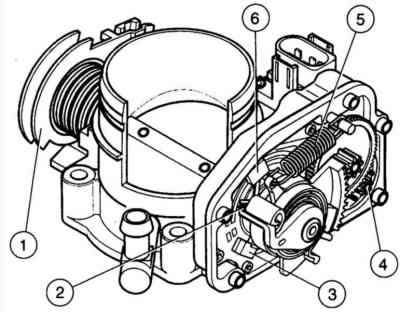

Throttle Controls

- 1 - throttle control lever;

- 2 - idle switch;

- 3 - throttle position potentiometer. The potentiometer tells the control unit about the throttle position;

- 4 - throttle servomotor;

- 5 - spring. When the power supply is interrupted, the spring moves the throttle valve to the main position. In this position, the accelerator cable does not move the throttle;

- 6 - throttle actuator position potentiometer. The throttle valve position potentiometer reports the position of the throttle valve actuator to the control unit.

The engine management system is a combined ignition and fuel injection system.

The fuel pump, immersed in the fuel tank, supplies fuel to the fuel line through the fuel filter. The fuel pressure in the system is controlled by a pressure regulator. The regulator allows excess fuel to return to the fuel tank when the pressure in the fuel system is exceeded. The fuel line is a reservoir for four fuel injectors that inject fuel into the intake ports of the engine cylinders. A sequential fuel injection system is used, in which the injectors inject fuel independently of each other. The control unit controls the fuel injector by changing the pulse width, that is, the length of time when the injector is open, to provide a richer or leaner fuel mixture.

The air passes through the air filter, air flow meter and throttle valve to the cylinder intake ports. The air flow sensor is a tape conductor that is energized (1), see fig. Conductor strip location (1) in the air flow meter. The constant temperature of the tape is maintained by electric current, which varies depending on the mass of passing air. The current that must be supplied to maintain a constant temperature of the tape is proportional to the mass of the air flow. Based on information from the air flow meter and other sensors, the control unit regulates the time and amount of fuel injected according to the measured amount of air and the engine speed. The longer the injector is open, the more fuel is injected.

Additional sensors transmit information to the control unit about the temperature of the coolant, the temperature of the air entering the engine, and on models with a catalyst about the oxygen content in the exhaust gases.

The activated carbon filter prevents harmful fuel vapors from escaping from the fuel tank into the atmosphere. Fuel vapors accumulate in a container with activated carbon and, when the engine is running, are burned in the engine cylinders.

The memory device in the control unit recognizes the malfunction that has occurred and records it. If an important sensor fails, the control unit switches to an emergency program so that the engine continues to run, albeit with less efficiency.

Visitor comments