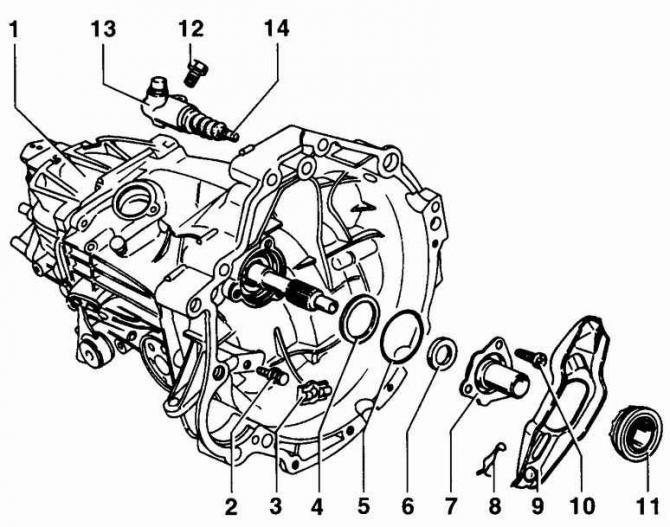

- 1 - gearbox,

- 2 - stud with a ball tip,

- 3 - intermediate element,

- 4 - disc spring,

- 5 - sealing ring,

- 6 - sealing ring of the input shaft of the gearbox,

- 7 - release bearing guide sleeve,

- 8 - spring,

- 9 - clutch release lever,

- 10 - self-locking bolt,

- 11 - release bearing,

- 12 - bolt, 20 Nm,

- 13 - clutch slave cylinder,

- 14 - pusher,

- 15 - flywheel,

- 16 - clutch disc,

- 17 - pressure plate,

- 18 - bolt, 25 Nm

Warning: Stud 2 ball end is lubricated with molybdenum disulphide grease.

Warning: Stud 2 tightening torques:

- in the gearbox housing made of aluminum alloy 25 Nm,

- in the gearbox housing made of magnesium alloy 20 Nm.

Warning: The convex side of the spring 4 must point towards the guide bush.

Warning: When installing o-ring 5, a new o-ring must be used.

Warning: Installation of the sealing ring 6 is carried out up to the stop.

Warning: Spring 8 is attached to the clutch release lever.

Warning: Tightening torques for self-locking bolt 10:

- to the gearbox housing made of aluminum alloy 35 Nm,

- to the magnesium alloy gearbox housing 25 Nm.

Warning: Do not wash the release bearing 11 in solvent, as the grease will be washed out of it.

Warning: Bearing 11, which makes noise when rotating, must be replaced.

Warning: Pusher head 14 is lubricated with molybdenum disulphide grease.

Warning: If the car is equipped with a flywheel 15, consisting of two sections, then the clutch disc 16 is installed without vibration damper springs.

If the flywheel 15 consists of one piece, then the clutch disc 16 is installed with vibration damper springs, and the springs must be on the side of the pressure plate.

Warning: Lubricate the splines of the clutch disc 16 with a thin layer of grease G000100. The lubrication layer must be thin and even, otherwise, during clutch operation, excess lubricant will be thrown onto the working surfaces of the clutch, which can disrupt its operation.

Warning: Tighten bolts 18 gradually and evenly in a diagonal sequence.

Visitor comments